Error Margin

When declaring the weight of a part, you have the option of defining the error margin applicable to the declared weight. Also, when computing the weight of a part, the error margin defined in the settings is taken into account. As a result, when computing the global weight of the assembly, the error margin applied to each part is then taken into account to compute the global error margin.

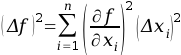

The following formula is used for the computation, where f is a function which depends on independent variables xi (where xi represents the parts):

Example

In an assembly containing:

- two instances of the part

x1, where the part has an error margin of 3g, - and one instance of the part

x2, where the part has an error margin of 10g,

the terms of the formula are:

Then, the formula becomes:

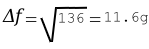

Which gives the following result: