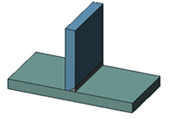

The affected representations are now prepared for the welding.

The bevel-butt weld appears in the tree:

- Its supports and their external references appear under the

bevel-butt weld.

- External references appear under the

External References node too.

- The weld preparation appears as

Assembly features

.

. - The welded 3D shapes are prepared.

- An assembly protected weld preparation is created and appears under the

Assembly features

node.

node.

- The welded 3D shapes are prepared.