About Joints | ||||

|

| |||

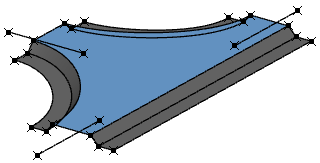

Just like concept surface, joints are composed of Sections, Link Outputs, and Face Outputs. You can modify a joint by adding sections or by modifying the support sketches. The modification of sketches is adopted by the joint and its Link Outputs and Face Outputs.

The joint creation is done in three main steps:

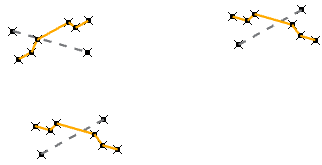

- In the first step, sections are assembled to a Joint element, which initially contain only the selected sections.

- If free sections are selected, for each section a guide curve is created. The sections are moved to the Joint element.

- If sections associated with concept surfaces are selected, copies of the sections are added to the Joint element. The guide curves of the support concept surfaces are also used for the joint creation.

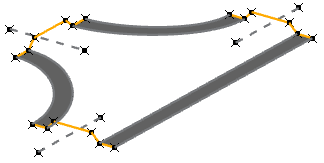

- In the second step, first connections are created with two curves selected on two different sections. The resulting faces are surfaces of the type Guided Loft

.

.

- In the third step, the connections are created for which more than two section curves for each face are selected. The resulting faces are surfaces of the type Fill Surface