-

From the Producibility section of action bar,

click Producibility for Forming

. .

-

Select a plies group.

The plies are listed in the same order as in the plies group. Rows named Die,

Interface, and Punch are added to visualize results such as sliding (Sliding is a

property of interfaces between plies). -

Select a ply in the dialog box and specify its reference point.

- Selection: Select an existing point.

- Indication: Pick a point location in the 3D area.

- Automatic: The reference point is the geometric center of

the ply.

-

Specify the step length used in the simulation mesh.

- Scaled: The step length is a ratio computed from the size

of each ply.

- Explicit: You enter a value.

-

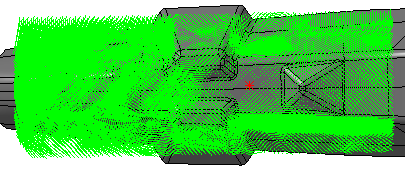

Click Preview.

- The simulation is run separately on each ply.

- The maximum shear and maximum deviation are listed for each ply.

-

Select the Results

tab and

select a ply under Selection.

This starts the post-processing of the selected ply.

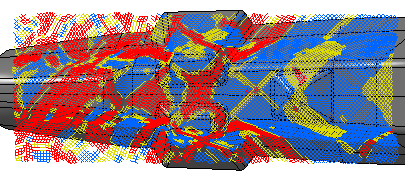

- Select Shearing angle from the list, and Producibility Mesh under Display Geometry to analyze the amount of shear resulting from the forming simulation.

- From the list, select Deviation to analyze the amount of deviation between the actual and the theoretical fiber direction.

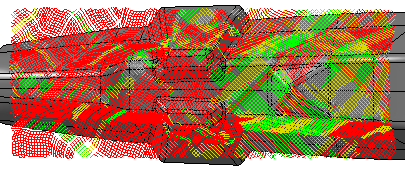

- Select an Interface between two plies, Sliding from the list, and Vectors under Display Geometry to analyze the amount of sliding that occurs during the forming process.

-

Validate to store the forming simulation (Forming under the

plies group).

- After a modification of the model shape, double-click Forming.

- Click Preview to update the simulation.

- Review the model as you did previously.

|

.

.