Key terms

Normal range, large range, small range, design range management, and design limits components play a prominent role in adjusting the computer capacity to properly model all elements at their real size.

- Design Range Definition

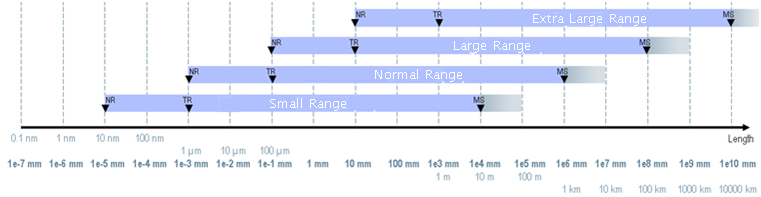

- The following figure illustrates the design range system expressed in metric units of

measure:

- Design Range Management

- Covers the usage of normal, small and large range. You can

combine normal and large range, or normal and small range options for various

objects within the same product structure to ensure the object model is

consistent with the real physical model you envision. The specification vary

from model to model depending on the industry. As an example, a bridge product

is created in large range and the pillar parts of the bridge in normal range.

The design range option is stored at the product or representation level

(Physical Product, Product, 3D Shape).

Handling multiple design ranges involves modifying the design range either at creation of an object or in the Design Limits tab that can be accessed through in Parameters and Measures sub-category.

- Design Limits

- A determined range system in which you can create products in the 3DEXPERIENCE platform. The lower and upper bounds vary from small to large range. Normal range is the default option and is sufficient in the majority of cases. Design limits are relevant in specific situations and accounted for in the calculation.

- Tolerant resolution (TR)

- Maximum size of gap for tolerant modeling.

- Model size (MS)

- Maximum coordinate value of topological elements.

- Small range

- Enables to create objects ranging from 0.00001 mm to 0.01 km.

- Normal range (NR)

- Enables to create objects ranging from 0.001mm to 1km. This standard design range is selected by default when you create an object.

- Large range

- Enables to upscale dimensions of models by creating objects from 0.1mm to 100 km.

- Extra large range

- Enables to upscale dimensions of models by creating objects from 10mm to 10.000km.