About Drop-Off | ||

| ||

A drop-off can be defined by:

- A drop-off curve, a slope, and a height:

- The drop-off curve is the reference curve driving the drop-off. It must be parallel to the reference surface. This curve is the top or the bottom of the ramp, if identified.

- The slope is the angle or drop-off ratio (for example 1:20) of the ramp with respect to the reference surface.

- The height is the height of the bottom curve. This parameter is associated with the slope to create the bottom curve.

- Or a drop-off curve and a bottom curve (Slope and height are not required).

- A ply border. If the top drop-off curve does not exist, you must identify a ply border that drives the drop-off. As a consequence, an offset of (thickness at top - thickness at geometrical level x) is required as input as well as the slope and height to compute the whole ramp from top to bottom.

If required, you can modify the limits of the drop-off:

- Start and end limits of drop-off curve allow an extrapolation of the drop-off curve to generate a greater surface.

- Left and right limits allow to relimit the ramp surface in width and to position it along its width (particularly valued to a tolerance to avoid gaps while intersecting the ramp with the context surfaces).

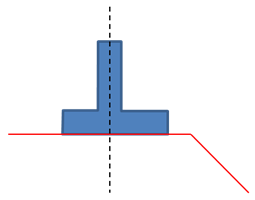

Centered Ramp Support

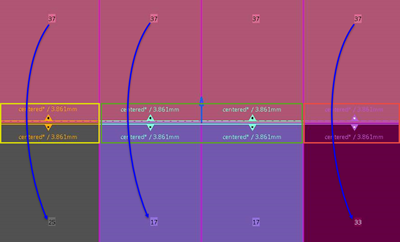

This option is proposed in Grid Panel when defining the staggering for structural reference elements or groups.

By default, the ply drop-off is placed after the structural element:

If you select Centered Ramp Support, the clearance distance of the

corresponding ramp supports is automatically computed to center the ramp supports under the

reference element. It applies to all reference elements. The clearance distance is defined

as a formula using the number of ramp support curves and the step between those

curves.

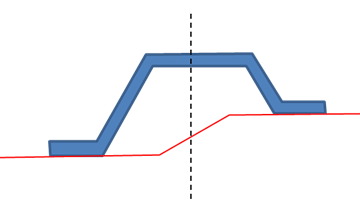

Centered Ply Drop (at Plies Generation)

This option is proposed in Grid Ramp Support and in Grid Panel when defining the staggering for structural reference elements or groups.

Centered Ply Drop (at Plies Generation) is another option proposed while defining the staggering.

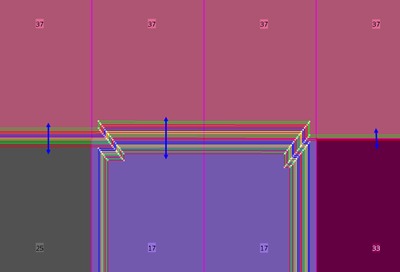

When plies are generated, ramp supports are created for each sub-staggering definition.

- The number of curves is computed from the number of plies to be dropped from cells on one side of the staggering definition scope to the other side.

- The clearance value is specified, or updated for existing ramp supports, using the computed

number of plies to be dropped.

The formula is - (#of plies - 1) x offset / 2: The bottom of the ramp is taken into account to center the ply drop.

- The clearance value is updated (if required) at each plies generation.

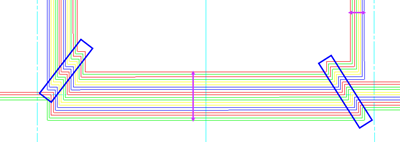

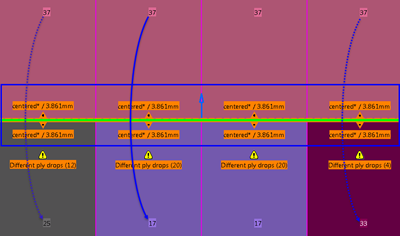

- It ignores the "steps" introduced in the ply contours by staggering definition change and/or

weight saving. In the image below, the double-headed arrows indicate a centered ply

drop. The blue squares indicate steps where the ply drop is not centered.

Steps are centered only when the ply drops before and after a staggering change are identical. In the image below

- The solid arrow stands for the first staggering definition.

- The dashed arrow stands for the second staggering definition.

- The ply drops before and after the staggering change are identical, the ply drop is centered (under double-headed arrow).

- If the ply drops between cells are different within a staggering definition, the largest ply drop is taken into account by the centering.

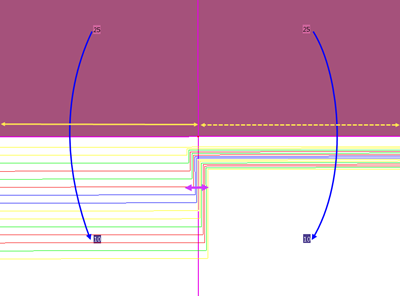

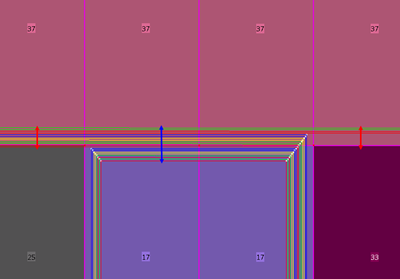

In the image below, there is one single staggering definition, resulting in three different ply drops, the largest one being in the middle.

The ply drops shown by the red double-headed arrows are not centered. The largest ply drop shown by the blue double-headed arrow is centered.

To center the ply drop along the whole structural reference element, define three sub-staggerings (one per ply drop - shown in yellow, green and red) instead of a single one.

The three resulting ply drops (blue double-headed arrows) are centered.

- Only ply drops from one cell to the other are taken into consideration.

- Unless the ply drops before and after a staggering definition change are the same, steps resulting from a staggering definition change or weight saving are not taken into account.

- If the ply drops between cells are different within a staggering definition, the largest ply drop is considered for centering.

Centered Ply Drop

This option is proposed in Grid Ramp Support.

When this option is selected:

- The distance of the first curve is computed from a formula based on the Curves count and the definition of the Slope value:

- For Step: F(x) = - ('Curves count' - 1) x 'Step' / 2

- For Rate: F(X) = - ('Curves count' - 1) x 'Rate' x 'Material thickness' / 2

- For Angle: F(X) = - ('Curves count' - 1) x ('Material thickness' / tan ('Angle')) / 2

- The ramp support is centered on the reference element.

- The plies drop-offs that use this ramp support are globally centered on the reference element.

- If ramp supports with the Centered ply drop check box selected exist on both sides of the reference element, they overlap.

Manage Drop-Off

This command interactively changes default plies drops with instant feedback on changes.

By default, ramp support curves are used from 1 to n: The first ply uses the first curve, the second ply uses the second curves, and so on. However, in some cases, mainly when the ply drop is driven by layer levels (Main Stacking Sequence), you may need to override the drop-off order (order in which the ramp support curves are used).

Another case is when you need to drop plies two by two. In this case, you can reduce the number of generated curves by specifying that the first curve is used by the first and second plies, the second curve is used by the third and fourth plies, and so on.

Manage Drop-Off

- Not only changes the order of ramp support curves of the plies contour, but also stores the

related drop-off order information on the corresponding ramp support.Note: The ramp support associated with the first ramp curve selected for the section identifies the ramp support drop order to consider.

- Keeps the drop order in design at plies generation update: Any drop order change is taken into account at the next plies generation.

- Consists in a local swap of edges in contour geometries and a change on drop-off order on ramp support curves used in stacking.

- Interactive changes are kept (Main Stacking Sequence).

- As a consequence, drop-off changes are applied to plies using curve of a same ramp support, associate with a single staggering definition on reference element (default or sub-staggering).