Assigning a Pin Jig Resource | ||

| ||

Click Play to watch the video:

-

From the

Authoring section of the

action bar,

click

Manage Structure Resources

.

.

-

In the

tree,

select a plate assembled item.

The Manage Structure Resources panel appears.Note: You can create a simplified process structure, thus minimizing the number of processes created using Part Planning - Simplified Mode.

-

Click

,

then select Pin Jig from the table.

Note: The existing Pin Jig resource works on an Assembly of Plates. As per a new Panel model, this treats the Panel as an assembly of plates. Thus the support of a Pin Jig Resource extends to a New Panel model as well since considers it as an assembly of plates.

,

then select Pin Jig from the table.

Note: The existing Pin Jig resource works on an Assembly of Plates. As per a new Panel model, this treats the Panel as an assembly of plates. Thus the support of a Pin Jig Resource extends to a New Panel model as well since considers it as an assembly of plates. -

Select;

- Catalog Browser

, the text appears Select or search an

object or Press ESC to exit. In the

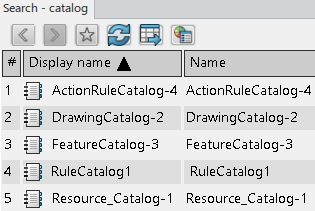

Search window, select

Catalog from the list window. Type your catalog

name or type catalog.

, the text appears Select or search an

object or Press ESC to exit. In the

Search window, select

Catalog from the list window. Type your catalog

name or type catalog.

All of the catalogs appear in the search tab window.

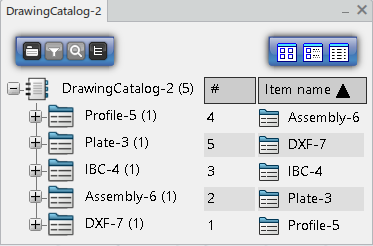

Double-click a catalog, example DrawingCatalog-2, this opens the catalog.

A Catalog is a tree structure consisting of the following elements:

- Chapters: A chapter references other chapters or items. Use to classify items by category.

- Items: An item is a reference to an external document or PLM Object. Items describe them with keyword values.

- Keywords: A keyword is an attribute describing a chapter or item. The Librarian can associate keywords to a chapter or item, and assign keyword values to each item. Search by keyword values to filter its content.

Libraries classify standard objects according to user-defined attributes. A Library consists of Classes, which categorize the objects in the Library hierarchy. Items are the actual objects that they manage.

Library to navigate, search, and select an item with better view and performance. The Library has a class and a description by an item.The keyword in the catalog replaces by an attribute in the library and the filter updates accordingly.

After a resource selection, the positioning information and auxiliary viewer updates with the resource and selected manufacturing assembly.

- Catalog Browser

-

Select

Compute Best Fit.

The best fit position calculates for the plate assembly.

-

Clear Automatic, then select a plane that is parallel to

the pin jig base-plane in the auxiliary viewer.

The plate assembly moves accordingly, and the pin height recomputes. The name of the selected plane is displayed in Support Base Plane.

-

Click

Modify Orientation.

The screen splits and a 3D viewer show the pin jig and plate assembly.

- Modify the position of the plate assembly as required using the Robot and click OK.

-

Click

Open resource in new tab

.

A new tab appears with the resource. The part body contains the plate assembly, and a new node creates for each of the pin jig resource that contains the pins.

.

A new tab appears with the resource. The part body contains the plate assembly, and a new node creates for each of the pin jig resource that contains the pins.