Part Planning - Simplified Mode | |||||

|

| ||||

From the Authoring section of the action bar,

select Part Planning

![]()

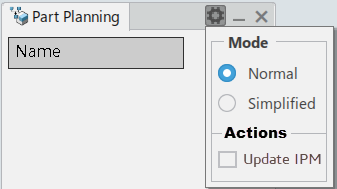

The Part Planning panel appears.

Select Settings ,

,

- Simplified mode:

- For flat parts (plate/profile), does not create the fabricated process.

- For curved parts (plate profile), only the fabricated process creates and the formed process does not create.

- Normal Mode: In this mode, all processes create as done previously.

By default, Normal mode is enabled.

Simplified model for Plate.

Simplified model for Profile.

This also supports the following Manufacturing Aids;

Launching the Synchronization Manager

![]() , it displays only the flattened IPMs of plate/profile with the required features for the

simplified models.

, it displays only the flattened IPMs of plate/profile with the required features for the

simplified models.

Click Compute to confirm the status and then click Synchronize to synchronize the features.

In the Update In-Process

Models

![]() this generates manufacturing features directly in the flattened part when part planning is in

Simplified Mode:

this generates manufacturing features directly in the flattened part when part planning is in

Simplified Mode:

For flat plate design objects, the manufacturing features generate in the In-Process Model as before.

For curved plate design objects:

- All manufacturing features create directly under the manufacturing representation of the flattened In-Process Model.

- Manufacturing features representing the flattened results create without any intermediate features.

- All the features supported in normal mode support in simplified mode.