This focuses on the generation of the following weld-based features in Flat

In-Process Model during Update In-Process Model execution on Simplified

Plate data. This includes the Attachment Line, Positive Margin, and Edge

Preparation.

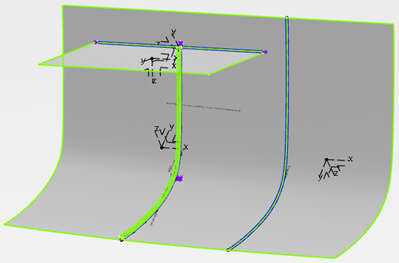

Manufacturing features generate under the Curved and Flattened In-Process Model (IPM) for a

Curved Plate Process. The features under Curved IPM are intermediate features, which help

feature generation in Flat IPM. The features generated in Flat IPM are of real use since

workshop documents generate based on them.

The features in Curved IPM are the intermediate featured. As a part of support for the

Simplified Plate data model, features generate only in the Fabricate In-Process Model (Flat

IPM). This reduces the time and resource spent in generating intermediate features.

Based on the Design Data the behavior is as follows

For Flat Plate: There are no changes in weld-based manufacturing

feature creation. It behaves as normal mode

For Curved Plate:

- There is no change in Weld-based feature generation in Normal mode.

- For Simplified mode:

- In-Process Models (Resulting products of manufactured parts)

- As per the simplified model, there are no feature containers (3D Shape, so

called MfgRep) under In-Process Models of the manufactured part.

- Therefore, there are no manufacturing features created as intermediate

features.

- Flattened In-Process Models (Resulting products of fabricate items)

- All Weld based features create directly under this object.

- Weld based features representing Flat results create without intermediate

features.

- All weld-based features supported in normal mode are the same in Simplified

Mode.

The Simplified model supports only a new fastener model. Therefore, the Weld-based feature

generation completes based on the new fastener model only.

Following are the weld-based features:

- Attachment line

- Attachment line generation on Joined part.

- Alignment line generation on Joined and Pilot Part.

- For the Butt case: Only the Alignment line generates on Joined and Pilot

Part.

- For the Lid case: Only the Attachment line generates on Joined Part.

- Margin generation:

- For Tee Weld joint: Positive margin feature generates on the Pilot Part.

- For Butt Weld joint: Positive margin feature generates on Pilot and Joined

Part.

- Edge Preparation feature

- For Tee Weld joint: Edge preparation feature generates on Pilot Part.

- For Butt Weld joint: Edge preparation feature generates on Pilot and Joined

Part.

These weld-based features are rule driven features. Corresponding rules define in the

PRM.

Supports all weld-based feature generation for all existing weld types for the Simplified

data model.

Following is the behavior of weld based features defined:

For Part Planning in Normal Mode

In In-Process Models, there are intermediate Weld based features represents features in

the formed design model. In Flattened In-Process Models use manufacturing features,

In-Process Models to position correctly in the Flattened Plate.

For Joined part:

For Pilot Part:

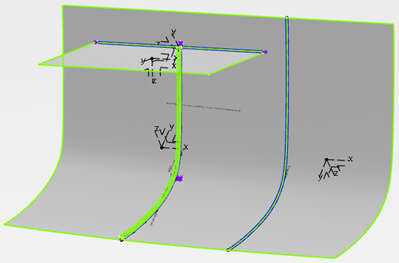

For Part Planning in Simplified Mode

-

Weld based manufacturing features in Flattened In-Process

Models are created directly without intermediate features creation. Thus, there are no

manufacturing features created under In-Process Models.

- Feature support - Supports all the Weld based manufacturing

features in normal mode is the same in Simplified Mode.

For Joined part:

For Pilot Part:

For Lid Plate:

- For Joined Part: Attachment line creates.

- For Pilot Part: Edge Prep and Margins create.