Strategy Parameters | ||

| ||

![]()

Strategy Parameters

- Strategy data window

-

This describes the Sequential Turning 1. Data window that stores: Rank, Status Type, Name, Tool Compensation, Feed Rate, Spindle Speed.

Right-click on any motion in the dialog box section to access the context menu.

- Column Order: Allows you to change the header column order with Up and Down commands.

- Column Filter: Allows you to filter the header columns.

- Properties: Allows you to modify the selected motion.

- Delete: Removes the selected motion.

- Cut: Cut the selected motion.

- Copy: Copy the selected motion.

-

Properties

Properties

- Edit the selected motion.

-

Delete

Delete

- Delete the selected motion.

-

and

and

- Change the rank of the selected motion.

-

Go

Go

- In

Go motion, the program positions the tool

with respect to one or two

check elements.

- Geometry tab

- First/Second Check Modes

- The tool is positioned with respect to each check

element depending on the

To,

On, and

Past mode:

- To: The position of the tool nose is tangent to the near side of the selected element with a possible offset.

- On: The position of the tool nose is on the selected element, with a possible axial or radial offset since normal offset, collision avoidance, and safety angles are not applicable.

- Past: The position of the tool nose is tangent to the far side of the selected element with a possible offset.

- Check Element

- The first check element is point, line, curve, or edge type elements. If it is a point, no second check element is selected. Otherwise, the second check element is line, curve, or edge type elements. When only one check element is selected, the tool is projected onto the check element. When two check elements are selected, the tool is positioned with respect to the two check elements.

- First/Second Check Limit

-

- Extended: When check limit mode is set to Extended, a virtual tangent element is added to each extremity of the check element before it is actually taken into account as a check element. Therefore, if there is no intersection between the drive and check elements, the final tool position may be located at the intersection of the drive curve and a tangent of the check element.

- Actual: When check limit mode is set to Actual, no virtual tangent element is added. Therefore, the final tool position is located on the check element.

Furthermore, control over geometric extrapolation is not controlled in the Follow motion but on the preceding motion that positions the tool on the drive element. Collision avoidance is taken into account for positioning in On mode, and that left and right safety angles are only considered in collision avoidance mode.

- Reference Point

- For the first

Go motion of an operation, you can

define a chosen direction of motion by means of a reference point. This

reference point is used in determining the exact tool position considering the

check modes, offsets, and so on.

Reference Point in the First Go Motion of the Operation: The tool positioning for the first motion of a Sequential Turning operation with respect to To, On, and Past mode is specified according to a reference point. This point is derived from the previous operation or is selected using the Reference Point symbol in the dialog box.

Reference point definition is optional. If a reference point is not defined, the tool is positioned by default with respect to the check elements depending on the To, On, and Past mode setting.

Click point symbol

in the

Geometry tab of the dialog box and

then select the required point or right-click the symbol to display the

following

context menu

commands:

in the

Geometry tab of the dialog box and

then select the required point or right-click the symbol to display the

following

context menu

commands:

- Select: Pick a point as a reference from the work area.

- Initialise from Previous: Automatically take a reference point that has been initialized from the previous machining operation or tool change. If the current Sequential Turning Operation immediately follows a tool change, then Initialise from Previous takes the tool change point as reference point. Otherwise it is the last point of the previous Machining Operation (which is the end point of the retract motion, if a retract motion is present on the previous Machining Operation ).

- Analyze: Visualize the reference point in the work area.

- Remove: Reject the previous selection and make a new selection.

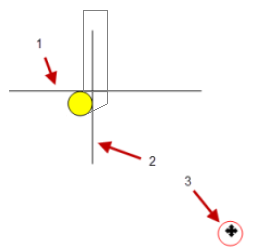

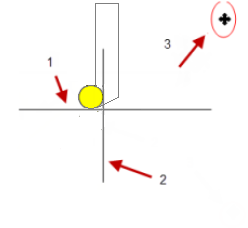

To illustrate reference point behavior, the figures below have identical check modes on both check elements. The only difference is the position of the reference point. Notice how a change in reference point affects the tool position.

1 is 1st Check Element

2 is 2nd Check Element

3 is Reference Point

The configuration is First check mode - TO, Second check mode - PAST

With a new reference point position:

Note: For reference points positioned on an intersection of check elements, use the ON mode to generate the toolpath. Otherwise, the toolpath is not correctly generated. - Offsets

- Specifies axial, radial, and normal offsets with

respect to each check element.

Note: The positioning mode (To, On, Past) and offsets are not applicable when the tool is positioned on a point.

- Strategy tab

- Feedrate mode

- Specifies

feedrate mode as:

- Machining

- Lead-In

- Lift-Off

- RAPID

- Other value

- Air cutting feedrate

- Local Feedrate

- Specifies local feedrate only when feedrate mode is Other value.

- Local spindle mode

- Specifies spindle speed.

- Collision avoidance for Check/Drive

- Collision avoidance for each check element when the tool is positioned in To or Past mode.

- Left and right safety angles

- Specifies left and right safety angles.

Available when Collision avoidance for Check check box is selected.

- Machining tolerance

- Specifies machining tolerance.

- Tool compensation

- Specifies tool compensation.

- Geometry tab

-

Go Delta

Go Delta

- In

Go Delta motion, the tool move is based on

the current position of the tool. The

To,

On, and

Past mode is not proposed.

- Geometry tab

- Delta check mode

- The following options are available when right-clicking

in the Delta check mode:

- Distance between two points: Select two points in the work area.

- Line and distance: Select line and distance in the work area.

- Angle and distance: Select angle and distance in the work area.

- Axial and radial: Select axial and radial offsets in the work area.

- Strategy tab

The following options are available:

- Feedrate and spindle speed

- Machining tolerance

- Tool compensation

- Geometry tab

-

Go InDirv

Go InDirv

- In

Go InDirv(Go in Direction Vector) motion,

the tool moves in a given direction up to the selected check curve. The tool is

positioned with respect to the selected element depending on the

To,

On, and

Past mode.

- Geometry tab

- Check Mode

- Specifies check mode as:

- To: The position of the tool nose is tangent to the near side of the selected element with a possible offset.

- On: The position of the tool nose is on the selected element, with a possible axial or radial offset since normal offset, collision avoidance, and safety angles are not applicable.

- Past: The position of the tool nose is tangent to the far side of the selected element with a possible offset.

- Drive Element Type

- Specifies drive element type as Line or Angle. Also specifies Angle of drive, if drive element type is Angle.

- Drive Direction

- Specifies drive direction as Same or Inverted.

- Check Limit

- Specifies check limit as Extended or Actual.

- Offset

- Specifies axial, radial, and normal offsets with respect to the check element.

- Strategy tab: The following options are

available:

- Feedrate and spindle speed

- Collision avoidance when the tool is positioned in To or Past mode.

- Left and right safety angles: Available when Collision avoidance for Check check box is selected.

- Machining tolerance

- Tool compensation

- Guiding Point, if you use a square or grooving insert.

- Geometry tab

-

Follow

Follow

- In

Follow motion, the tool follows a drive

element up to a check element. The check element is to be clicked the

Follow motion and is an edge, line, a curve,

or a point.

- Geometry tab:

The drive element is a curve on which a preceding motion positions the tool Therefore, the preceding motion must be a Go, Go InDirv, or Follow motion. A Go to a point or a Go Delta cannot precede a Follow motion.

- Drive direction

- Specifies

Same or

Inverted.

This is useful in the particular case when two positions are reachable.

- Offset

- Specifies axial, radial, and normal offsets with respect to the check element.

- Control over Geometric Extrapolation of Check Limit

-

If the preceding motion is a Go motion, the first selected check curve is used as drive curve for the Follow motion.

If the preceding motion is a Go InDirv motion, the selected check curve is used as drive curve for the Follow motion.

If the preceding motion is a Follow motion, the check element of the preceding Follow motion is used as drive curve. This occurs when this check element is not a point and the Change Drive option of the preceding Follow motion is set. Otherwise, both consecutive Follow motions share the same drive curve.

Notes:- The offsets applied to follow the drive element are also based on the same preceding motion. When the drive and check curves are tangent, any offset values on the check curve must be the same on the tangent drive curve.

- The collision avoidance and the control over geometry extrapolation on drive curve are also based on the same preceding motion.

- Check mode

-

The tool follows the drive element up to the check element. The final tool position is determined by the To, On, and Past mode.

- To: Tool nose tangent to the drive element and before the check element with a possible offset.

- On: Tool nose tangent to the drive element and on the check element, with a possible axial or radial offset since normal offset is not applicable.

- Past: Tool nose tangent to the drive element and after the check element with a possible offset.

- Strategy tab: The following options are

available:

- Feedrate and spindle speed

- Collision avoidance for Check.

- Left and right safety angles: Available when Collision avoidance for Check check box is selected.

- Machining tolerance

- Tool compensation

- Guiding Point, if you use a square or grooving insert.

- Geometry tab:

-

GoTo Point

GoTo Point

- With

GoTo Point motion:

- If the motion is the first in the sequence, the tool moves from the last point defined in the previous operation, to the point defined in the GoTo Point motion.

- In other cases, the tool moves from the last point defined in the previous motions, to the point defined in the GoTo Point motion.

- Offset

- Specifies axial and radial offsets with respect to the check element.

-

PP Word

PP Word

- Inserts a tool motion defined by PP word statements (access to a PP word table is available if one is defined on the machine of Part Operation).

Sequential Turning Behavior Based on Guiding Point

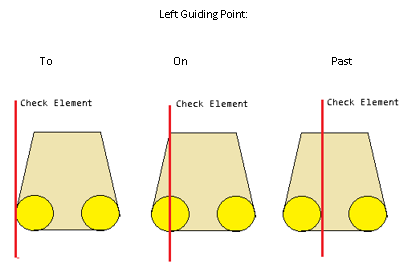

- Left Guiding Point

- Left Guiding Point positions the insert

based on the left radius of Insert, such as the P9 compensation point. The

following pictures show the behavior for a groove insert:

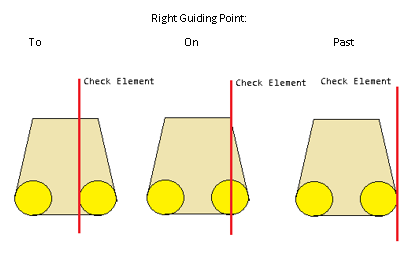

- Right Guiding Point

- Right Guiding Point positions the insert

based on the right radius of insert, such as the P9R compensation point. The

following pictures show the behavior for a groove insert: