B-Axis Management

A Tool Axis symbol on the turning operation's Strategy tab allows the B-axis orientation to be set and eliminates the need for a tool change activity.

Tool Axis for Turning Operation

Tool axis is defined on turning operations linked to a mill turret (managing a B-axis). Information that B-axis is managed on turret is defined on the machine.

Turret type is defined as Mill Turret on the NC machine.

No tool axis is defined on turning operations that gave rotary turret defined. Tool axis is defined according to the spindle axis system.

A spindle axis system is defined on each spindle. Tool axis is defined on the main spindle axis.

For all Machining Operations affected to the counter spindle, the tool path computation is always done according to the main spindle axis system. If capability to compute coordinates in the counter spindle is provided, the tool axis of Machining Operation affected to the counter spindle is defined in the counter spindle axis system.

Tool axis is defined by geometry selection or manually (by component values or angle value). Angle orientation is defined from the radial axis to the axial axis of the spindle axis system. See Defining the Tool Axis

Tool Path Replay

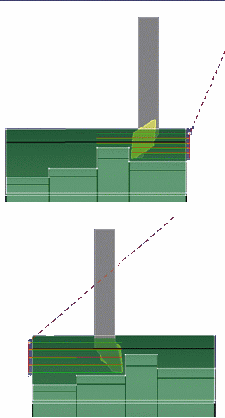

For turning operation defined on a mill turret (on which B-axis is defined), the tool is displayed according to the orientation defined by the tool axis. The tool axis specified by you is displayed on the Simulate or Display dialog box and is generated in the APT output.

B axis = 0 degrees

B axis = 90 degrees

For turning operation defined on another turret (not a mill turret), the tool axis is vector normal to the turning plane.

Output File Generation

BAXIS NC command is output at the beginning of Machining Operation defined on a mill turret.

$$ OPERATION NAME : Rough Turning.1 $$ Start generation of : Rough Turning.1 $$ FEDRAT/ 0.3000,IPR SPINDL/ 70.0000,RPM,CCLW BAXIS/1.000000, 0.000000, 0.000000 GOTO / 58.63072, 0.00000, 136.34210 GOTO / 58.63072, 0.00000, 134.34210 FEDRAT/ 0.4000,IPR GOTO / 58.63072, 0.00000, 81.85882 FEDRAT/ 0.8000,IPR GOTO / 58.84286, 0.00000, 82.07095

This syntax contains valuation of I, J, K coordinates of the operation tool axis (defining the B-axis orientation). Coordinates are defined in the machining axis (spindle axis). For example: BAXIS/1,0,0.

Turret axis orientation components (I, J, K) are generated in the output file according to the options set in Tool Motions in the NC Output tab of Machine Editor dialog box.

TLAXIS syntax (that is output for a machine axis change) is not modified: coordinates of TLAXIS statement are the components of the vector normal to the turning plane.

For the following statement the output depends on the options set in Tool Motions:

- GOTO statement

- TLAXIS (output for machine axis change)

- BAXIS to indicate B-axis orientation.

Operation Defined on a Mill Turret

NC data format statement = (X,Y,Z):

X, Y, Z

BAXIS/I,J,K

TLAXIS/Inormal, Jnormal, Knormal (components of the normal to the turning plane)

NC data format statement = (X,Y,Z,I,J,K):

X, Y, Z, I, J, K

Operation Defined on Another Turret

NC data format statement = (X,Y,Z):

X, Y, Z

TLAXIS/Inormal, Jnormal, Knormal (components of the normal to the turning plane)

NC data format statement = (X,Y,Z,I,J,K):

X, Y, Z, Inormal, Jnormal, Knormal

Inormal, Jnormal, Knormal are the components of the axis vector normal to the turning plane. I, J, K are the components of the tool axis orientation vector that define the B-axis position.

Machine Simulation

B-axis move is simulated according to the tool axis defined on the turning operation.

APT Source File Import

Import of APT source file on which I, J, K coordinates are defined; tool axis is defined with the I, J, K coordinates.

At replay and simulation, if tool axis is not correct (not in the turning plane) then radial axis is used for tool assembly orientation.

BAXIS syntax is correctly interpreted by APT import functionality only when the syntax is defined with a known order of parameters. The required parameters of the syntax must respect the default syntax. Tool path is correctly replayed only when:

- All the required parameters are set

- The parameters are set in the specified order.

Major word and parameters must be set as follows:

BAXIS,/%MFG_MILL_TURRET_I_AXIS, %MFG_MILL_TURRET_J_AXIS,

MFG_MILL_TURRET_K_AXIS

Change in Machining Operation Status

If you change the turret assigned to a machining program from one turret type to another type. That is, from Rotary to Mill Turret or vice versa. The Machining Operation status becomes Not up to date.

If you cut, copy, and paste a Machining Operation related to one turret type to another turret type (for example, from Rotary Turret to Mill Turret or inversely), the Machining Operation can have status Not up to date.