About Machining Batches | ||

| ||

For more information on using the batch monitor, see Accessing the Batch Monitor.

For more information on running a batch, see Run a Batch Directly from the Batch Monitor.

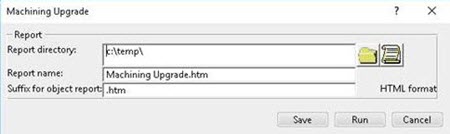

Machining Upgrade

This batch allows you to migrate Machining data created in V5. As PLM data model has changed, previous data created before V6R2013x must be upgraded. This batch:

- Creates an NC assembly under the machining cell and instantiates product assembly children under the NC assembly and sets the position matrix.

- Reroutes the link between the part operation and NC assembly.

- Migrates geometrical links.

- Generates a final report on data migrated and errors encountered.

Machining Resource Management

This batch allows you to:

- Use Replace Resource to replace resources that are duplicated during File-based Design Import. For example, when two V5 processes containing similar resources are imported in 3DEXPERIENCE.

- Use Transition List to apply a specific maturity to imported resources. This helps to control sharing and ability to reuse the imported resources.

This batch uses the results generated by Machining File-based Design Import. For more information, see Machining File-based Design Import.

This batch generates a final report on data migrated and errors encountered.

Machining Update NC Resources

This batch allows you to migrate all resource data in a database from one version to another. For example, from 3DEXPERIENCE R2017x to 3DEXPERIENCE R2018x.

This batch generates a final report on data migrated and errors encountered.