Using Knowledge in Machining Processes | ||

| ||

Knowledge Expressions in Machining Operations in a Machining Process

You can associate Knowledge expressions to Machining Operations within a Machining Process. These expressions have the the form of Formulas and Checks, and Tool Queries, and allow establishing relations on data such as features, machines, and tools that are not yet known at the Machining Process build time. For example, you can use this capability to determine the depth of cut from the hole depth.

In addition, you can use f(x) capability to link the various parameters of Machining Operations. For example, for a Machining Process where a rework phase follows a roughing phase, the offsets of the rework is determined from the offsets used in the roughing step.

Apply Machining process on User Defined Features

During the definition of Machining Process, you are able to set links between the Machining Operation and the Geometry through the User Defined feature.

At Machining process application time, the geometrical links are replaced by same links referencing the selected User Features. It is possible to group User Defined features as a single feature for the same machining operation which provides a better automation of the Machining Program definition for the same family of parts. See Using User Defined Functions

Parameters on Machining Operations and Features

Parameters is added in Machining Operations and features in the Knowledge Advisor Application.

In this case, the Machining Process View displays a generic node named Parameters under the machining object node. Under this generic node appears the parameter node with its name, its value and/or its Formula (depending on the Knowledge parameter display setting).

Hole.Hole type = "Tapered"

Knowledge Check in a Machining Process

As for Machining Operations, you can associate a Check to a Machining Process to constrain the domain of app of the Machining Process.

Formula Editor, Checks Editor, and Tool Query Dialog Boxes

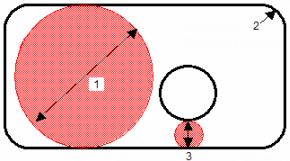

The Formula Editor, Checks Editor, and Tool Query dialog boxes have several common areas.

- All the expressions of the current entity (Tool Query or Machining Operation for a Machining Process, and for a Machining Operation, either Formulas or Checks).

- Commands list

- Area for editing the current expression with restrictions and help for using Operator, Function and Unit lists.

- All the possible attributes that you can use in an expression,

according to the Knowledge description:

- The different KnowledgeWare Packages which group

a set of object types. Note: The Machining Resources, Machining Features, and Machining Activities packages are always available.

- The object Type list for the selected package.

- The Attribute list for a selected type: select an attribute to insert it in the expression.

- The different KnowledgeWare Packages which group

a set of object types.

- For the Tool Query dialog box, a fifth area allows you to define the tool type and tool repository.

Feature Attributes for Checks, Tool Queries, and Formulas

The dialog box that appears for Tool Queries, Checks, and Formulas allows you to access to the list of feature attributes with their type. Below are some examples.

Hole Features

Hole type attribute for Checks:

-

Hole.Hole type = "Simple"(simple hole) Hole.Hole type = "Tapered"(taper hole)Hole.Hole type = "Counterbored"(counterbore hole)Hole.Hole type = "Countersink"(countersunk hole)Hole.Hole type = "Counterdrilled"(counterdrilled hole)

Limit type attribute for Checks:

Hole.Limit type = "Blind"Hole.Limit type <> "Blind"Hole.Limit type = "Up_To_Last"-

Hole.Limit type = "Up_To_Next" -

Hole.Limit type = "Up_To_Surface"

Bottom type attribute for Checks:

Hole.Bottom type = "Flat"Hole.Bottom type = "V_Bottom"

Threaded and Tap side attributes for Checks:

Hole.Threaded = trueHole.Threaded = falseHole.Tap side = "Right_Threaded"Hole.Tap side = "Left_Threaded"

SemanticDimtabValue attribute for tolerance Checks:

Hole.Diameter.SemanticDimtabValue="H7"Note: You must select theDiameterattribute before entering theSemanticDimtabValue="H7"string.

ToleranceMax and ToleranceMin attributes for tolerance Formulas or Tool Queries (example):

Diameter = Hole.Diameter+(Hole.Diameter.ToleranceMax-Hole.Diameter.ToleranceMin)/2Note: You must select theDiameterattribute before entering theToleranceMinorToleranceMaxstring.

Machinable Axial Features

Hole type attribute for Checks:

Machinable Axial Feature.Hole type = 0(simple hole)Machinable Axial Feature.Hole type = 1(taper hole)Machinable Axial Feature.Hole type = 2(counterbore hole)Machinable Axial Feature.Hole type = 3(countersunk hole)Machinable Axial Feature.Hole type = 4(counterdrilled hole)Machinable Axial Feature.Hole type = 5(Unknown)

Hole Extension attribute for Checks:

Machinable Axial Feature.Hole Extension = 1(blind)Machinable Axial Feature.Hole Extension = 2(through)

Hole bottom type attribute for Checks:

Machinable Axial Feature.Hole bottom type = "Flat Bottom"Machinable Axial Feature.Hole bottom type = "V Bottom"

Hole bottom angle attribute for Checks (examples):

Machinable Axial Feature.Hole bottom angle = 0degMachinable Axial Feature.Hole bottom angle = 120deg

Threaded and Thread direction attributes for Checks:

Machinable Axial Feature.Threaded = trueMachinable Axial Feature.Threaded = false-

Machinable Axial Feature.Thread direction = "0"(Right threaded) Machinable Axial Feature.Thread direction = "1"(Left threaded)

IsToleranced and ToleranceType attributes for tolerance Checks (examples):

Machinable Axial Feature.IsToleranced = trueMachinable Axial Feature.ToleranceType("Diameter") = "H7"

ToleranceMax and ToleranceMin attributes for tolerance Formulas or Tool Queries (example):

Machinable Axial Feature.Diameter+(Machinable Axial Feature.Diameter.ToleranceMax-Machinable Axial Feature.Diameter.ToleranceMin)/2Note: You must select theDiameterattribute before entering theToleranceMinorToleranceMaxstring.

Prismatic Machining Areas

There are three dedicated length attributes for Formulas, Tool Queries, and Checks:

- Maximum channel width

- Minimum corner radius

- Minimum channel width

Maximum channel width attribute (examples):

Prismatic machining area.Maximum channel width<=100mmPrismatic machining area.Maximum channel width>48mm

Minimum channel width attribute (examples):

Prismatic machining area.Minimum channel width<=20mmPrismatic machining area. Minimum channel width>10mm

Minimum corner radius attribute (examples):

Prismatic machining area.Minimum corner radius<=8mmPrismatic machining area.Minimum corner radius>6mm

Tool Queries using geometrical attributes

Cutter diameter:

Nominal diameter>=Hole.Diameter-0.1mmNominal diameter<=Hole.Diameter+0.1mm

Cutting length:

Cutting length>=Hole.Depth*1.2Cutting length<=Hole.Depth*2

Tool Queries using technological attributes

Way of rotation:

Way of rotation=RIGHT_HAND

Cutting material:

Tooth material desc.=COATED_HIGH_SPEED_STEEL

Check for Type of Feature

Standard hole:

Hole.Diameter.SemanticDimtabValue<>"H7"Hole.Threaded=false

Hole with fitting:

Hole.Diameter.SemanticDimtabValue="H7"Hole.Threaded=false

Threaded hole:

Hole.Diameter.SemanticDimtabValue<>"H7"Hole.Threaded=true

Diameter attribute before entering

the SemanticDimtabValue="H7" or

SemanticDimtabValue<>"H7" string.Check for Size of Feature

Hole diameter:

Hole.Diameter>4mmHole.Diameter<=20mm

Hole depth:

Hole.Depth<=Hole.Diameter*3.5

Formula

Formulas are used to compute parameters (mainly parameters of a Machining Operation) with a Formula containing feature attributes.

Diameter attribute before entering

the ToleranceMin or ToleranceMax string.