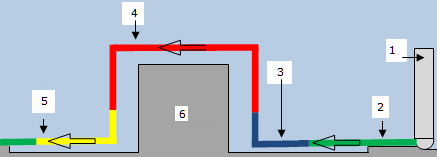

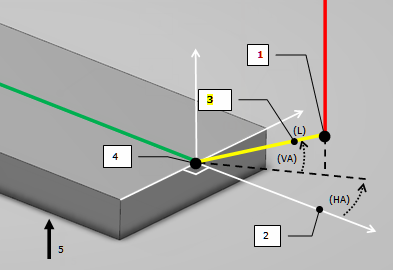

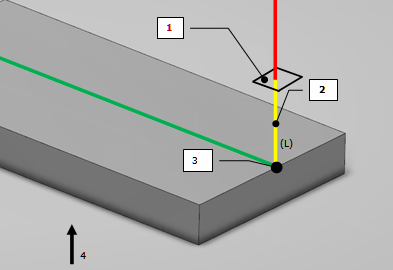

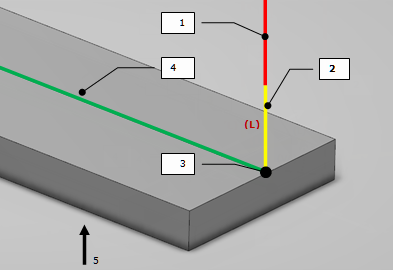

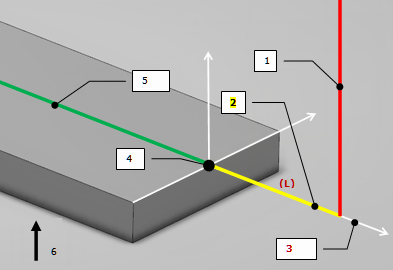

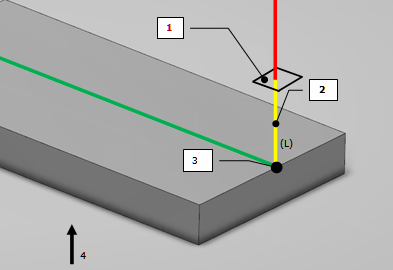

Axial Motion

This motion is a linear motion, built with:

- Length (L), defined along Tool Axis direction.

This motion is always collision free. Then it is the last solution when all NC Macro modification strategies have failed.

- Linking motion

- Axial motion

- Macro point

- Machining motion

- Tool axis

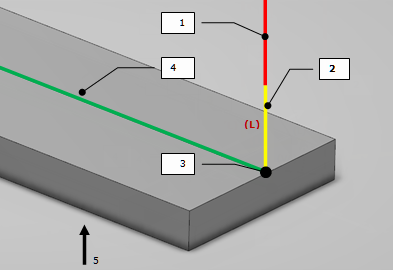

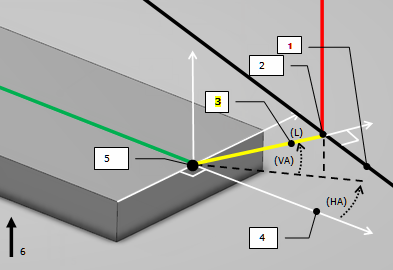

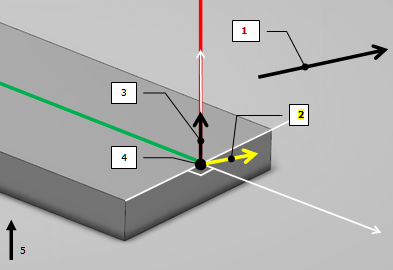

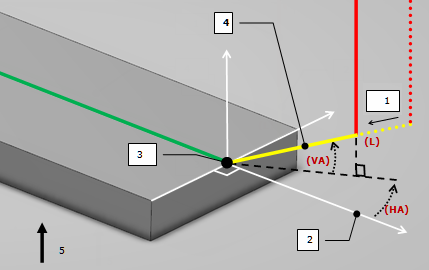

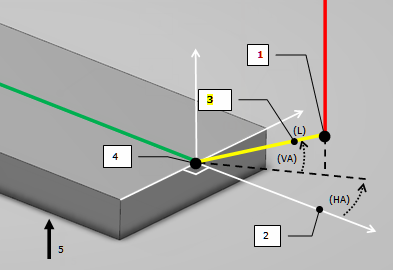

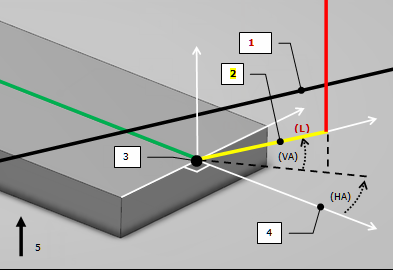

Horizontal Motion

This motion is a linear motion, built with:

- Horizontal angle (HA).

- Vertical angle (VA).

- Length (L).

In case of collision, the first step is to:

- Reduce macro length (L); the residual length, in plane, must be greater than tool diameter.

If no solution is found, a new strategy is applied:

- Horizontal angle (HA) varies around its initial value.

- If required, vertical angle (VA) is increased (up to Tool Axis).

- And length (L) can be reduced as described.

If no solution is found again, a last strategy is applied.

Axial motion is called with the following parameters: length (L) value.

- Macro reduction due to collision detection

- Tangent vector

- Macro point

- Horizontal motion

- Tool axis

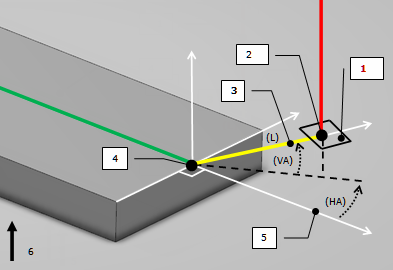

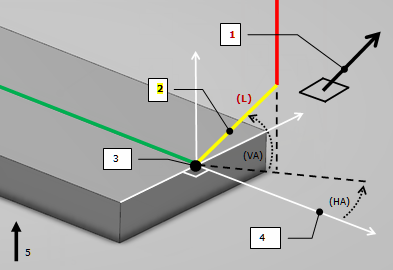

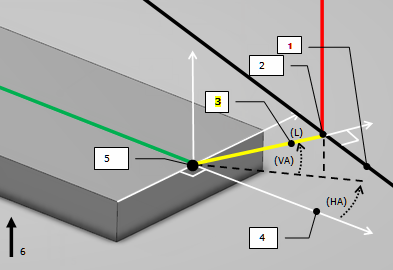

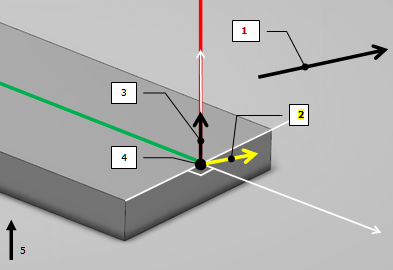

Tangent Motion

This motion is a linear motion, built with:

- Tangent Vector (tangent to trajectory on macro point)

- Length (L)

If collision is detected, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) = 0 rad.

- Vertical angle (VA) = 0 rad.

- Length (L) does not change.

- Linking motion

- Tangent motion

- Tangent vector

- Macro point

- Machining motion

- Tool axis

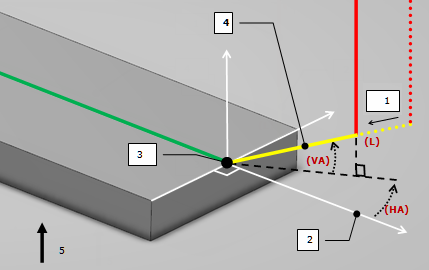

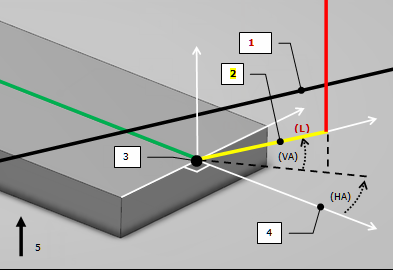

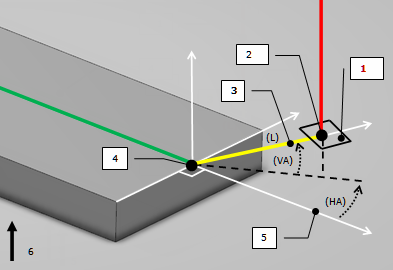

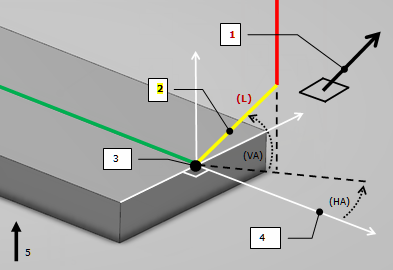

Motion to a Point

This motion is a linear motion, built with:

If collision is detected, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) see picture.

- Vertical angle (VA) see picture.

- Length (L) distance between Macro point and Selected Point.

- Selected point

- Motion to a point

- Tangent vector

- Macro point

- Tool axis

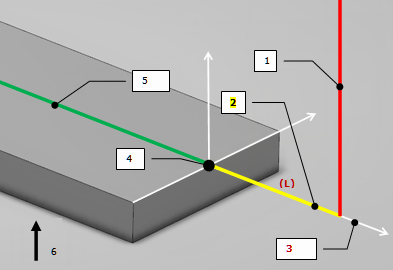

Motion to a Line

This motion is a linear motion, built with:

- Selected Line on which the Macro point will be

projected.

If collision is detected, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) see picture.

- Vertical angle (VA) see picture.

- Length (L) distance between Macro point and projected point

- Selected Line

- Projection of macro point on the selected line

- Motion to a line

- Tangent vector

- Macro point

- Machining motion

- Tool axis

Motion Perpendicular to a Plane

This motion is a linear motion, built with:

- Selected Plane on which the Macro point will be projected.

If collision is detected, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) see picture.

- Vertical angle (VA) see picture.

- Length (L) distance between Macro point and projected point

- Selected plane

- Projection of macro point on the selected plane

- Motion perpendicular to a plane

- Macro point

- Tangent vector

- Tool axis

Distance Along a Line Motion

This motion is a linear motion, built with:

- Selected Line that gives a direction.

- Length (L), to reach.

If collision is detected, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) = 0 rad.

- Vertical angle (VA) = 0 rad.

- Length (L) does not change.

- Selected line

- Distance along a line motion

- Macro point

- Tangent vector

- Tool axis

Axial Motion up to a Plane

This motion is a linear motion, built with:

This motion is always collision free.

- Selected plane

- Axial motion up to a plane

- Macro point

- Tool axis

Tool Axis Motion

This motion is a linear motion, built with:

If collision is detected, Tool Axis motion varies between the selected axis and initial

tool axis to find a position without collision.

If no position is found, macro is not applied.

Note:

This behavior is the current one.

- Selected axis

- Tool axis motion

- Initial tool axis

- Macro point

- Tool axis

Normal Motion

This motion is a linear motion, built with:

- Selected Normal to a Surface

- Length (L)

If collision is detected, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) see picture.

- Vertical angle (VA) see picture.

- Length (L) does not change.

- Selected normal to a surface

- Normal motion

- Macro point

- Tangent vector

- Tool Axis

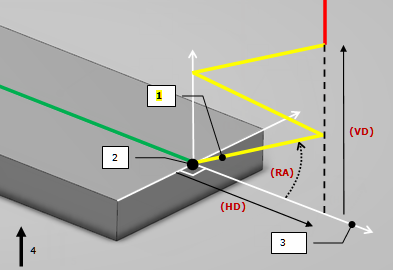

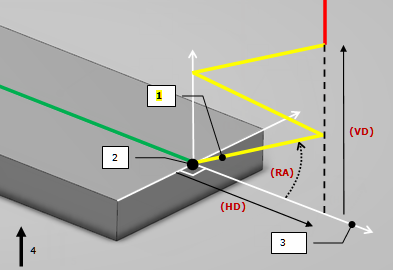

Ramping Motion

This motion is a linear motion, built with:

- Horizontal Safety Distance (HD).

- Vertical Safety Distance (VD).

- Ramping Angle (RA).

If collision is detected, a new strategy is applied.

Axial motion is called with the following parameters:

- Length (L) = Vertical Safety Distance (VD)

- Ramping motion

- Macro point

- Tangent vector

- Tool axis

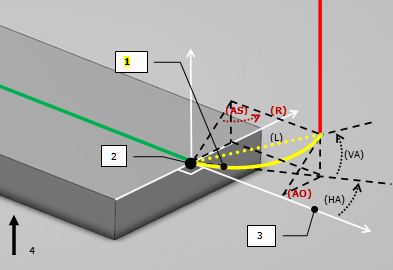

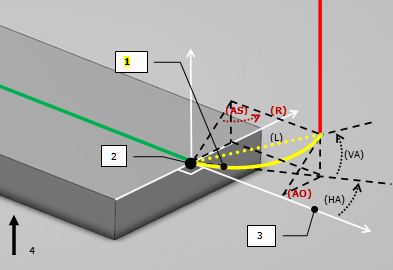

Circular Motion

This motion is a linear motion, built with:

- Angular Sector (AS).

- Angular Orientation (AO).

- Radius (R).

If collision is detected, the first step is to:

- Increase Angular Orientation (AO) up to 90 degrees.

- Reduce Angular Sector (AS) by keeping distance in plane between macro point and arc extremity, greater than tool radius.

If no solution is found, a new strategy is applied.

Horizontal motion is called with the following parameters:

- Horizontal angle (HA) see picture.

- Vertical angle (VA) see picture.

- Length (L) see picture.

- Circular motion

- Macro point

- Tangent vector

- Tool axis

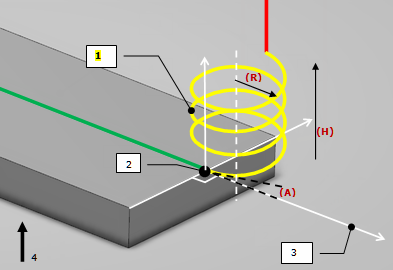

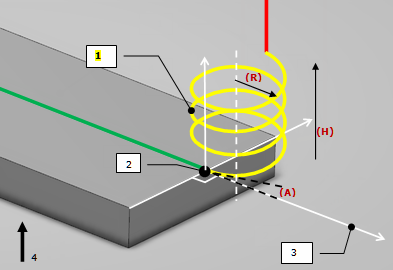

Helix Motion

This motion is a helix motion, built with:

- Radius (R)

- Height (H)

- Angle (A)

If collision is detected, the first step is to:

- Reduce macro length by keeping distance in plane between macro point and helix extremity, greater than tool radius.

If no solution is found, a new strategy is applied.

Ramping motion is called with the following parameters:

- Horizontal Safety Distance (HD) = 2 x Radius (R).

- Vertical Safety Distance (VD) = Height (H).

- Ramping Angle (RA) = Angle (A).

- Helix motion

- Macro point

- Tangent vector

- Tool axis

PP Word List

This motion is collision free.