- From any Product:

-

Select a machining

app

then the

Programming

section.

An empty

Manufacturing

Cell is created with an

Activities Process

Tree.

-

Create a generic machine or assign a

machine from the database.

As soon as a

machine is assigned to the

Manufacturing

Cell,

a

Part Operation

and a

Manufacturing Program

are created in the

Activities Process

Tree.

-

Alternatively, open an existing

Machining Process

or

PPR Context.

By default, the

Activities Process

Tree

is available.

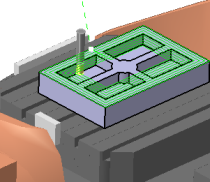

- Click Workpiece Automatic Mount

. . - Create a machining operation.

- In the Activities Process

Tree, click Activate/Deactivate Machine Kinematic to deactivate the machine kinematic and press the Play button of the Compass.

-

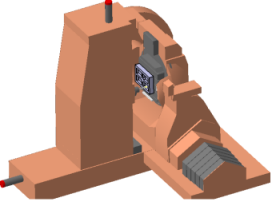

From the View section of the action bar, click Hide/Show Machine

to verify that the machine can reach the part at the

current tool position. to verify that the machine can reach the part at the

current tool position.

A Check Reachability dialog box appears indicating whether the position is

reachable:

- If reachable, the machine goes to the position.

- If the position is out of limits or unreachable, then the machine is displayed with the tool at the home position.

The axis locked

by machine instructions before the current Machining Operation are also taken into

account to move the machine in the position.

- Click OK in the Check dialog box to return to the replay

mode.

|