About Using the Synchronize Production Drawing and BOM XML | ||||

|

| |||

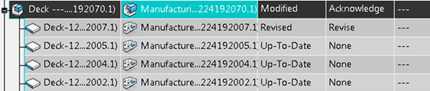

Sometimes there are some modifications for a specific manufacturing assembly in a session and that assembly has an attached Production Drawing or BOM XML. In this case, the Sync Manager shows Modified status for a specific manufacturing assembly row after computation.

The Sync Manager updates Production Drawing or BOM XML by the following conditions:

- The Sync Manager displays Modified status for a

manufacturing assembly row after computation if the Production

Drawing, which is attached to a manufacturing assembly, shows a

Update

flag.

flag.

After synchronization, Production Drawing is updated by the Sync Manager

- BOM XML contents are compared with a corresponding manufacturing

assembly. To compare BOM XML contents with all children or direct

children, the Is Direct Children attribute is added to the

XML Info element. In addition, this Boolean attribute corresponds

to the Consider Direct Children Only option of the

Production Drawing command. This BOM XML

is generated with the Consider Direct Children Only option and

the Sync Manager compares BOM XML contents

with direct children of Manufacturing Assembly00000002. If

BOM XML is generated without the Consider Direct

Children Only option, then Sync Manager considers all

children manufactured items Manufacturing Assembly00000002.

Refer to the comparison result, Sync Manager shows Modified status for the corresponding manufacturing assembly row. After synchronization, BOM XML contents are refreshed

Here are five scenarios about changing a child manufactured item:

- New - If manufactured items are planned for generation under an assembly,

then the assembly structure changes and its attached Production

Drawing or BOM XML needs updating. After computation,

Sync Manager changes the parent manufacturing assembly-row-status

to Modified. If the parent assembly has no computing, then the

status is not changing and documents are not the latest.

After a new manufactured item is created by clicking synchronize, then Production Drawing or BOM XML that are attached to Manufacturing Assembly00000049, Manufacturing Assembly00000005, MW_Section are updated.

Changing the Acknowledge action to None, action for the assembly row, the corresponding documents do not update.

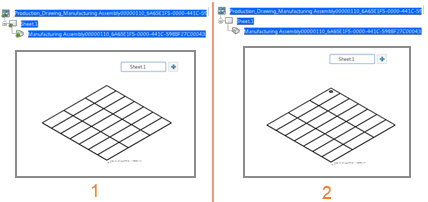

Adding a manufactured item for a Pillar to the Manufacturing Assembly00000002 and a Production Drawing updates after synchronization.

1 - Before Synchronization

2 - After Synchronization

In the BOM XML example, a new Manufactured Part00000017 element adds to BOM XML.

- Modified : Sync Manager captures the position

change of the design product and the modified design-product attribute values, which are

mentioned in DELMnOSynchronizePLMAttributes.CATRule. After computation, the

Sync Manager displays Modified status for

the selected manufacturing assembly row.

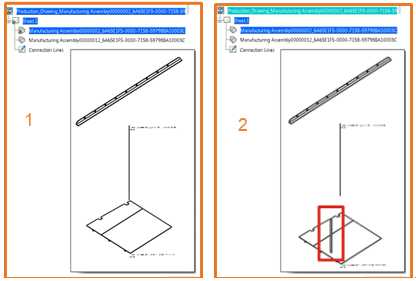

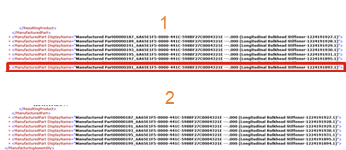

After synchronization, Production Drawing and BOM XML attached to manufacturing assembly are updated. In the Production Drawing example, (1) one deck stiffener was moved manually and Drawing is updated after synchronization (2).

1 - Before Synchronization.

2 - After Synchronization.

In the BOM XML example, Thickness="20mm" was added to the description attribute on the deck stiffener and BOM XML is properly updated after synchronization.

- Revised - The Sync Manager shows Revised status for a manufactured item

if the design product is revised and the implement link is broken. Before this highlight,

Sync Manager shows Up-To-Date status for the manufacturing

assembly row even though the child row has a Revised status.

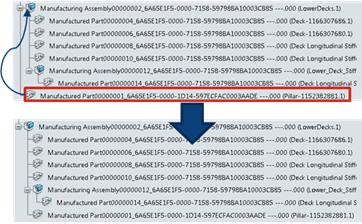

The parent manufacturing assembly-rows that have Production Drawing or BOM XML that show a Modified status after computation if the child manufactured item needs a revision. Not computing the parent manufacturing assembly-row or it does not have documents, then its status does not change to Modified.

After clicking the Synchronize command, a manufactured part revises and the Documents that are attached to the parent manufacturing assemblies update together. To update attached documents, the parent manufacturing assemblies, compute in advance.

A drawing updates with a revised deck that has an opening creation on a deck.

In the BOM XML example, the revision attribute and display name are changed after synchronization.

- Deleted - If a product was deleted, then the Sync Manager shows the

corresponding manufactured Item as having a Deleted status. If its parent manufacturing

assembly computes in advance, then the parent manufacturing assembly-row shows a Modified

status because the structure of the manufacturing assembly changes. In this case, its

Production Drawing or BOM XML must update

together.

After synchronization, Production Drawing and BOM XML that are attached to the parent manufacturing assemblies update.

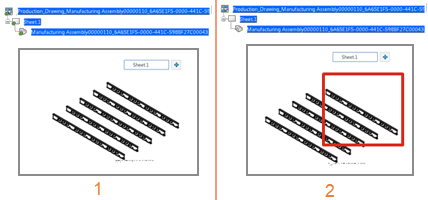

Here, one LBHD stiffener is deleted from Production Drawing after synchronization.

1 - Before Synchronization

2 - After Synchronization

In the BOM XML example, Manufactured Part00000201 has been deleted after synchronization.

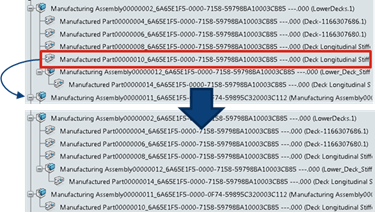

- Reroute case - If the manufactured item is rerouted to another

manufactured item, then the structure is changed and the corresponding

documents need to be updated.

- Supported: If "Manufactured Part00000001" is moved to

"Manufacturing Assembly00000002", then Sync Manager is able to

update Production Drawing or BOM XML attached to Manufacturing

Assembly00000002.

- Not Supported: If "Manufactured Part00000010" moves to "Manufacturing

Assembly00000011," then the implement link of Manufacturing Assembly00000002 removes.

In this case, the Sync Manager cannot update the Production

Drawing or BOM XML of Manufacturing

Assembly00000002. The Sync Manager displays an Unknown status

and action for the corresponding row. Therefore, the user has to update them by using

the Production Drawing command.

- Supported: If "Manufactured Part00000001" is moved to

"Manufacturing Assembly00000002", then Sync Manager is able to

update Production Drawing or BOM XML attached to Manufacturing

Assembly00000002.