- From the Surface Machining section of the action bar, click Multi-Axis Curve Machining

. .

A Multi-Axis Curve Machining entity is added to

the manufacturing program.

The dialog box opens at the Geometry tab

.

- Still in the Geometry tab, set the Curve Machining mode to Between 2 curves to drive the contact point.

- Still in the Geometry tab, click the top guiding curve in the icon. In the Edge Wizard that appears, in the option dialog box

, set Link types to Line insert, then select edges on the part. , set Link types to Line insert, then select edges on the part. Note:

Any

gaps between the edges are filled thanks to the Insert

link option.

-

Still in the Geometry tab, set the Curve Machining type to Side to drive

the flank of the tool.

-

Go to the Strategy tab

to specify parameters for:

to specify parameters for:

- Machining

- Tool path style to Zig zag

- Machining tolerance

- Direction of cut to climb

- Sequencing to Radial first (by segment)

- Max discretization step

- Max discretization angle

- Type of contouring to Circular

- Forced contour to None

- Close contour overlap (%)

- Radial

- Distance between paths

- Number of paths

- Axial

- Maximum cut depth

- Number of levels

- Tool Axis

- Tool axis mode to Tangent axis

- Mode to Along ruling direction

- Allowed lead to 30deg

- Fanning distance to 1000mm

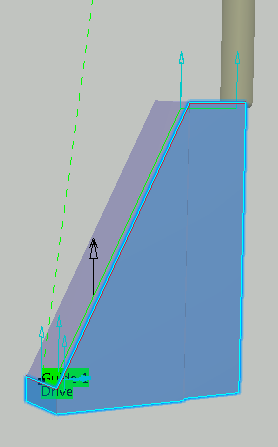

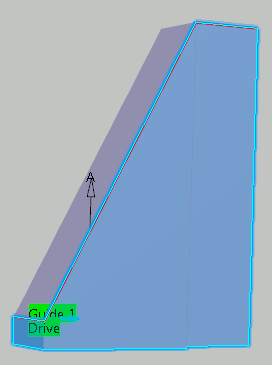

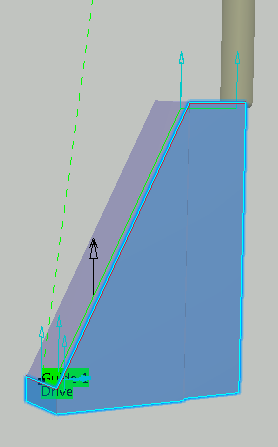

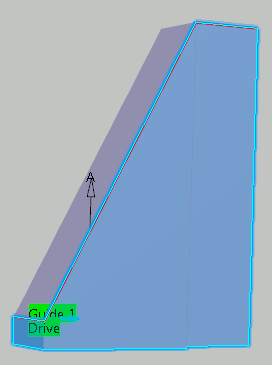

- Click the sensitive drive element in the icon, then select drive

surfaces in the work area.

A default reference tool axis is displayed in the work area. Note:

When machining a strip (or band) for faces, the tool axis is

deduced from the isoparametrics of the faces in order to ensure

continuity of the trajectory.

- If

needed, click the tool axis arrow

(A) in the sensitive icon, then specify a different

tool axis direction.

You can do this by selecting a surface. In

this case the surface normal is used. - Go to the Tools tab

to select a tool. to select a tool. - Go to the Feeds and Speeds tab

to specify the feedrates and spindle speeds for the machining operation. to specify the feedrates and spindle speeds for the machining operation.

- Go to the Macros tab

to specify the machining operation transition paths (approach

and retract motion, for example). to specify the machining operation transition paths (approach

and retract motion, for example).

-

Click Display or

Simulate to check the validity of the machining operation.

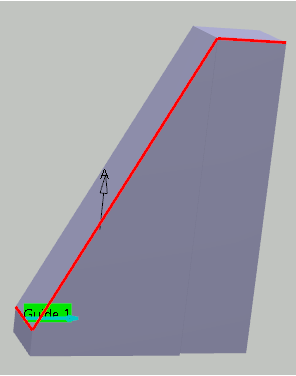

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

- Click OK in the Display or

Simulate dialog box, and again in the main dialog box to create the machining operation.

The tool path is created.

|

.A Multi-Axis Curve Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab

.A Multi-Axis Curve Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab .

.

, set Link types to Line insert, then select edges on the part. Note: Any gaps between the edges are filled thanks to the Insert link option.

, set Link types to Line insert, then select edges on the part. Note: Any gaps between the edges are filled thanks to the Insert link option.

to specify parameters for:

to specify parameters for:

to select a tool.

to select a tool. to specify the feedrates and spindle speeds for the machining operation.

to specify the feedrates and spindle speeds for the machining operation.

to specify the machining operation transition paths (approach

and retract motion, for example).

to specify the machining operation transition paths (approach

and retract motion, for example).