The

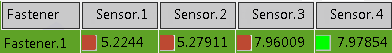

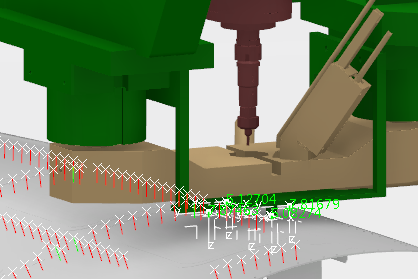

resource moves to the respective fastener location and the distance is shown with the distance annotation.

Since there is a handle attached to the sensor, you can change the status of sensor in the work area by clicking on the line turns the respective sensor toggle On or Off status or by selecting in the Computation Results table.