General Information

The Prismatic Machining Area features are associative.

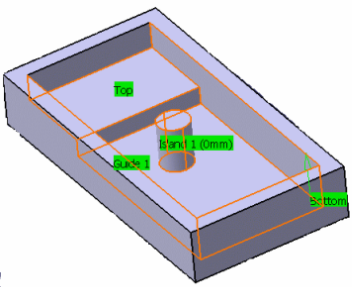

When running Feature Recognition, the milling areas (with non-planar top element) are taken into account for feature creation (Prismatic Machining Area). Checking is done on bottom face only, whereas conditions are not applied on top face. The top face is any surface, it does not need to be planar which is parallel to bottom face.

Feature recognition provides a Prismatic Machining Area corresponding to a Complex Pocket. The boundary is defined by a hard boundary only. An imaginary contour at the intersection of Hole and Slot is automatically defined to close the hard contour.

Formulas, Checks and Tool Queries

Prismatic Machining Area features is used in formulas, checks and tool queries in machining processes and machining operations (for example, to find the appropriate tool to machine the machining area). Example: Look in: MillAndDrillToolAssembly, Cutting length>Prismatic machining area.Depth or Nominal diameter<Prismatic machining area.Minimum corner radius*2

Search Queries

Prismatic Machining Area features is used in search queries. 'NC Machine'.'Prismatic machining area'.'Minimum corner radius'>5mm

Bottom Color Attribute for Prismatic Machining Area feature

The Bottom Color is the new parameter in the Machining Area Parameters dialog box. The Bottom Color parameter value gets updated after you select the bottom in 3DEXPERIENCE platform for Prismatic Machining Area feature. The value of Bottom Color parameter is in form of RGB value and is stored as string. The format/syntax of value is: (Red value, Green value, and Blue value).

If bottom is not selected for Prismatic Machining Area feature then the Bottom Color parameter in the Machining Area Parameters dialog box attribute is displayed as NONE.

In case, if you change the color of the bottom in 3DEXPERIENCE platform, then you have to edit the Prismatic Machining area feature dialog box to get the updated value of the Bottom Color parameter.

Bottom Color parameter is available in knowledgeware expressions such as "formula" and "checks" for different operations in machining process. It is seen from formula in Knowledge action bar for respective Prismatic Machining Area feature.

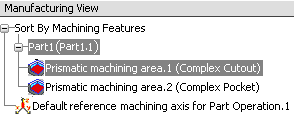

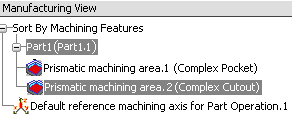

Associativity of Prismatic Machining Areas

A Prismatic Machining Area in the Manufacturing View has associated geometry in the part. Typical geometry could be:

- Top element

- Bottom element

- Boundary profile

- Other Prismatic Machining Area parameters such as minimum corner radius.

If the geometry is modified in the part document, then corresponding parameters and surface information for Prismatic Machining Area are updated in Manufacturing View to reflect correct values.

- the depth of complex pocket is changed so that it becomes complex cutout

- the boundary profile of a complex pocket is modified in such a way that it becomes a complex step, blind slot or through slot.

Such changes are not associative.