Manual Support Creation

When Create Manual Supports is selected, the Manual

Support Creation dialog box appears. You can use this dialog box to

create defined supports in specific support zones, compute support zones, and view a

quick preview of computed support zones.

You can manually define support zones by defining the Zone and

Support parameters.

Support Structure Propagation

You can propagate the current part to a product support structure on positioned part,

using Propagate Structure.

The Propagate On dialog box displays all the valid, eligible

instances for support propagation.

This option is only displayed if:

- The positioned part has calculated support structures.

- There is more than one occurrence of the positioned part that originates

from a singular part to produce.

It is only possible to propagate support structures if the two positioned parts are

defined along the same X-Y plane and have the same rotation along the Z-axis.

Copy Support Properties

You can copy the shape of the current support to a selection of other supports.

This command can be accessed by:

- Clicking Copy Properties

from

the context toolbar that appears when you select a support structure in the work area. from

the context toolbar that appears when you select a support structure in the work area.

- Clicking Copy Supports to other instances from the

support context menu in the manufacturing view.

Only supports with an identical structure (surface, edge, or point) can be selected

for duplication.

Support Structure Assessment

You can specify various support parameters using the Support Structure

Assessment dialog box.

Open the Support Structure Assessment dialog box by doing one of

the following:

- Click Quick Support Analysis

from the context toolbar in the work area when establishing the build layout. from the context toolbar in the work area when establishing the build layout.

- Click Analysis

from the Generate Support

Structure dialog box. from the Generate Support

Structure dialog box.

You can use the Support Structure Assessment dialog box to:

- Edit the minimum surface angle for the set of facets needing supports.

- Edit the maximum surface angle for the set of facets needing supports.

- Edit the orientation of the part using the Robot while the command is active. This command dynamically evaluates the

surface area for the modified orientation.

Based on the color chosen for the minimum/maximum surface angle, color legend updates

itself, and the color changes gets reflected on the facets of the overhanging parts.

The following parameters can be modified:

| Parameter |

Description |

| Minimum surface angle

|

Specifies the minimum surface angle allowed on

the part. |

| Maximum surface angle

|

Specifies the maximum surface angle allowed on

the part. |

| Transparency

|

Specifies the transparency of the color

visualization. |

| Supported Zones Area

|

Indicates the computed surface area of the

support zone. This measurement is given in square meters.

|

| Supported Edge Length

|

Indicates the computed surface area of the

edge length. This measurement is given in square millimeters.

|

| Number of Supported

Points

|

Indicates the number of supported points.

|

| Occlusion WRT

Front-face

|

True: Displays only the previewed

zones visible in the current view.

False: Displays all previewed zones.

|

Wire Support Edition

You can select, edit, and delete wire support structures in the work area.

Use the commands in the context toolbar to edit or delete a selected support structure face.

You can also use the Scaling

command to display a Robot that allows you to scale supports on the bottom or an intermediate level. command to display a Robot that allows you to scale supports on the bottom or an intermediate level.

Note:

This command is only available with wire support structures.

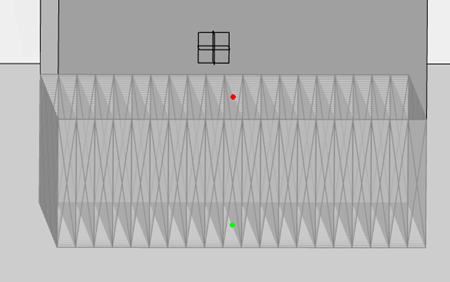

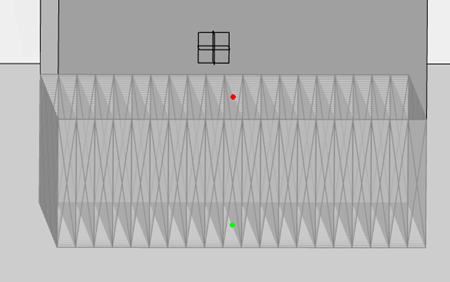

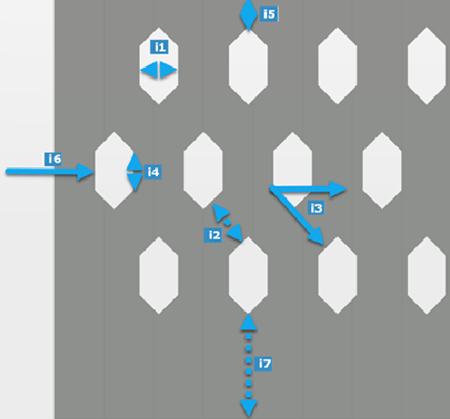

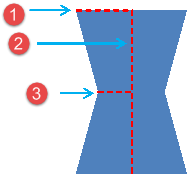

Wire Angled Support Creation

You can create an angled wired support structure.

Select a wired support in the work area, then select Edit Supports

from the context toolbar. Manipulation points appear in the work area if it is possible to create an angled support structure. Points that appear in

red cannot be manipulated, whereas points that appear in green are open to

manipulation. from the context toolbar. Manipulation points appear in the work area if it is possible to create an angled support structure. Points that appear in

red cannot be manipulated, whereas points that appear in green are open to

manipulation.

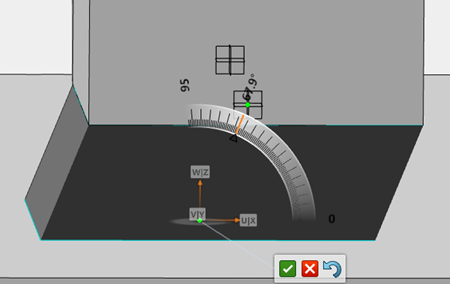

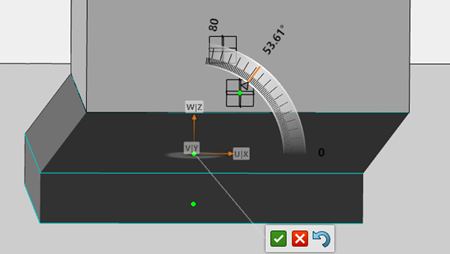

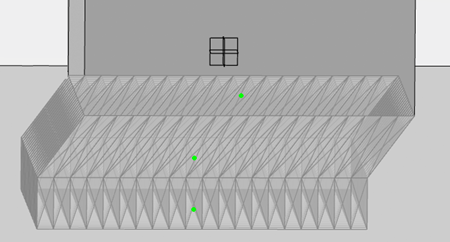

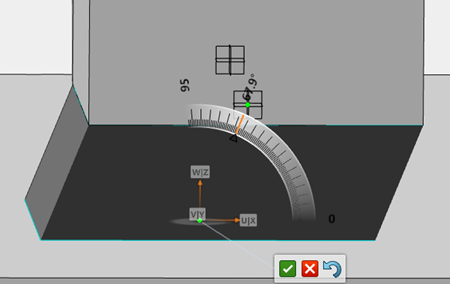

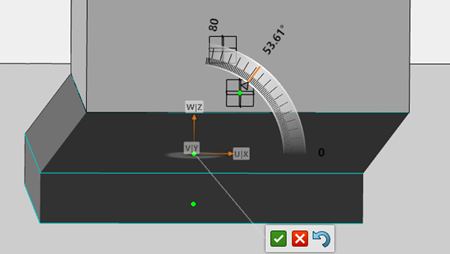

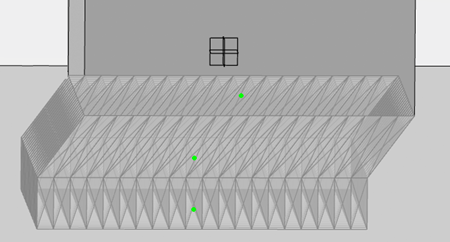

Clicking a green manipulation point displays a Robot that you can use to define the various angles of the angled support. Moving the

Robot dynamically recomputes the support structure.

Along the X-axis:

Along the X and Y-axis:

When you are finished, use the context toolbar to validate, reject, or revert your changes.

Rules for Generating Supports

You can generate supports by creating rules that apply to the whole part or to

specific zones of the part only.

Assign or edit a support rule using:

- Create or Edit Rules

command in the

Generate Support Structure dialog box. command in the

Generate Support Structure dialog box.

- Rules Management

command in the

Setup section of the action bar. command in the

Setup section of the action bar.

Note:

Before creating support structure rules, you must define zones on the part where

supports need to be specified, and choose a shape for the supports.

Zones

Lets you define an area on the part where to generate supports.

A zone corresponds to an area defined between a minimum angle value and a maximum

angle value. You can generate supports on:

Depending on the zone selected, the following parameters are available:

- Surface

-

| Parameter |

Description |

| Minimum Surface

Angle

|

Minimum angle between the part

surface and build tray surface. The value must be

less than 90°. |

| Maximum Surface

Angle

|

Maximum angle between the part

surface and build tray surface. The value must be

greater than or equal to 0. |

| Minimal Surface

Width

|

Precision of the zone

computation. |

| Tolerance

|

Specifies the maximum

deviation allowed between the design part and the

manufactured part. |

| Ground

Type

|

Lets you decide if the roots

of the support structure stand on the build tray,

on the part or on both. |

- Edge

-

| Parameter |

Description |

| Minimum Edge

Angle

|

Minimum angle between the part

edge and build tray surface. The value must be

less than 90°. |

| Maximum Edge

Angle

|

Maximum angle between the part

edge and build tray surface. The value must be

greater than or equal to 0. |

| Computation |

Lets you specify the support's computation

method:

Can be either:

- All: follows the sharp

edges

- Lowest line: detects the

lowest line on the part.

|

| Minimum

Length |

Minimum length of the lowest

line. Note:

Only available if

Computation is set to

Lowest line.

|

| Exclude Edge

Already Supported

|

Ignores the part edges at an

angle that equals the maximum angle value with

respect to the build tray. |

| Maximum Angle for

Zones Already Supported

|

Maximum angle allowed between

the part surface and build tray. This value is

used for the Exclude edges included in

surfaces supported parameter. |

| Ground

Type

|

Lets you decide if the roots

of the support structure stand on the build tray,

on the part or on both. |

- Point

-

| Parameter |

Description |

| Exclude Points

Included in Surfaces and Edges

Supported

|

When selected, ignores the

points of the part at an angle that equals the

maximum angle value with respect to the build

tray. |

| Maximum Angle for

Zones Already Supported

|

Maximum angle allowed between

the part surface and build tray. |

| Ground

Type

|

Lets you decide if the roots

of the support structure stand on the build tray,

on the part or on both. |

Shapes

The following shapes are available for supports:

-

Wire Wire

-

Conical Conical

-

Tree Tree

-

Volume Volume

- None

| Wire |

Conical |

Tree |

Volume |

|

Depending on the type of zone selected

(Surface,

Edge, or

Point), the following

parameters are available:

| Parameter |

Description |

| Pattern

Type

|

Lets you choose between an

offset or grid pattern. |

| Spacing

|

Specifies the density of the

pattern. |

| Radial

Offset

|

Specifies the offset

spacing. |

| Direction

angle

|

Specifies the direction of

the grid support structure. See Additional Wire Support Parameters. |

| Z Offset to

Top |

Creates a void between the

support structure boundary and the top

zone. |

| Z Offset to

Bottom |

Creates a void between the

support structure boundary and the bottom

zone. |

| Rib

width

|

Specifies the width of the

transverse reinforcement. |

| With

envelope

|

Creates an additional wire

that follows the peripheral loop of the surface

zone. |

| Fragmentation

|

See Additional Wire Support Parameters. |

| Fillet |

Adds fillet perforations on

the support. |

|

| Parameter |

Description |

| Cone

Radius

|

Specifies the radius of all

the nodes in direct contact with the part.

|

| Space Between

Cones

|

Specifies the distance

between cones to control the density of the

supports. |

| Radial

Offset

|

Specifies the offset

spacing. |

| Z Offset to

Top |

Creates a void between the

support structure boundary and the top

zone. |

| Z Offset to

Bottom |

Creates a void between the

support structure boundary and the bottom

zone. |

| Fillet |

Adds fillet perforations on

the support. |

|

| Parameter |

Description |

| Leaf

Radius

|

Specifies the radius of all

the nodes in direct contact with the part.

|

| Radius Increase

Rate

|

Specifies the rate at which

the tree thickens from the leaves to the root of

the tree. |

| Branch Internal

Thickness

|

Specifies the skin thickness

for hollow branches. If the value equals zero, the

branches are considered solid. |

| Maximum

Angle

|

Specifies the maximum angle

allowed for branches with respect to the building

direction. |

| Space Between

Leaves

|

Specifies the spacing

between leaves to control the density of the tree.

|

| Radial

Offset

|

Specifies the offset

spacing. |

| Z Offset to

Top |

Creates a void between the

support structure boundary and the top

zone. |

| Z Offset to

Bottom |

Creates a void between the

support structure boundary and the bottom

zone. |

| Fillet |

Adds fillet perforations on

the support. |

|

| Parameter |

Description |

| Motif

|

Customizes the solid

structure by letting you select any polyhedral

motif you have created. |

| Scale

|

Specifies the scaling factor

applied to the motif before replication, to

control the density of the lattice structure.

|

| Skin

Thickness

|

Creates a solid skin around

the lattice structure when you specify a value.

|

| Z Offset to

Top |

Creates a void between the

support structure boundary and the top

zone. |

| Z Offset to

Bottom |

Creates a void between the

support structure boundary and the bottom

zone. |

| Fillet |

Adds fillet perforations on

the support. |

Note:

Negative values are accepted for Offset on Volume

supports. With negative values, the support

structure penetrates the part, but not the build

tray.

|

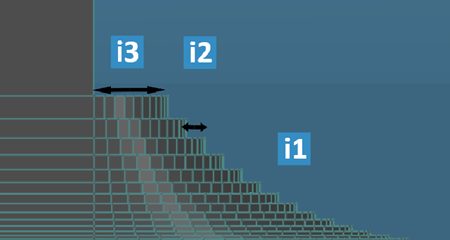

Fillet

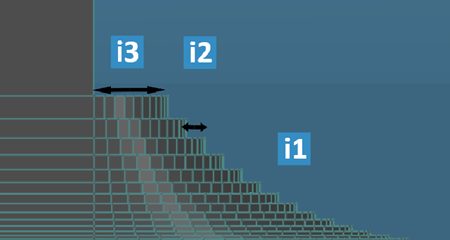

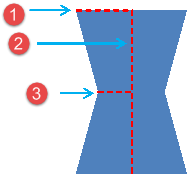

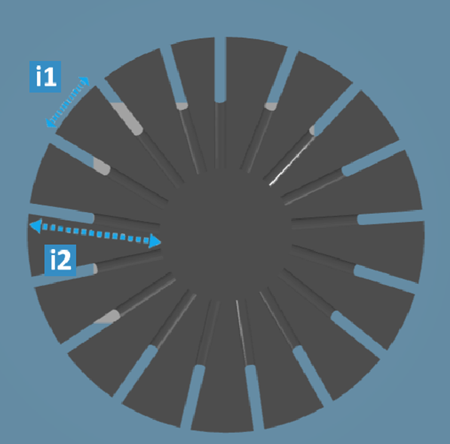

- Fillet on Wire

-

| Legend |

Parameter |

Definition |

| i1 |

Fillet

Radius

|

Specifies the perforation

radius |

| i2 |

Fillet Wired

Spacing

|

Specifies the perforation

spacing. |

| i3 |

Fillet Wired

Offset

|

Specifies the perforation

offset. |

- For the Perforation parameters, see Perforation.

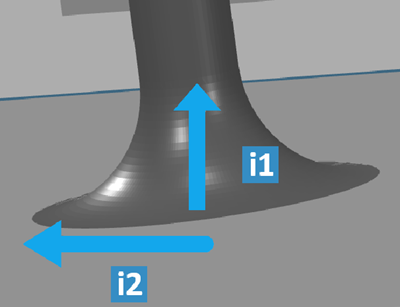

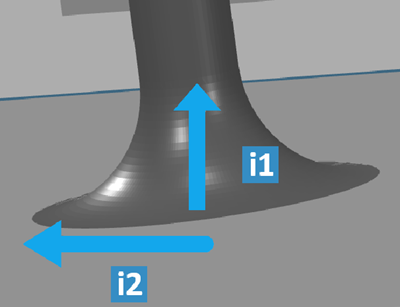

- Fillet on Conical, Tree, and Volumic Shapes

-

- Fillet on Conical and Tree

Shapes

| Legend |

Parameter |

Definition |

| i1 |

Fillet

Radius

|

Specifies the perforation

radius |

- Fillet on Volumic Shape

| Legend |

Parameter |

Definition |

| i1 |

Fillet

Height |

Specifies the perforation

height |

| i2 |

Fillet

Radius

|

Specifies the perforation

radius |

- The perforations are defined by their shape, their spacing pattern, and their depth.

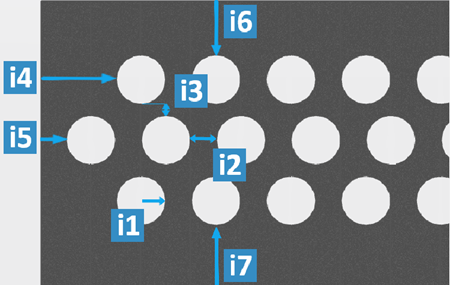

- Perforation Shape

-

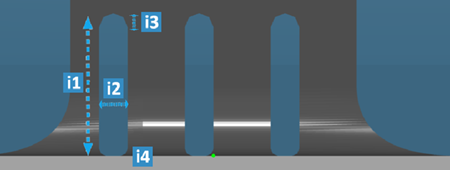

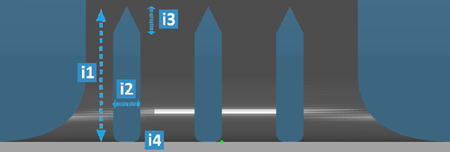

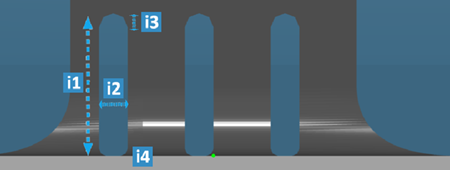

- Cylindrical

| Legend |

Parameter |

Definition |

| i1 |

Height

|

Specifies the perforation

height |

| i2 |

Width |

Specifies the perforation

width |

| i3 |

Top

Radius

|

Specifies the perforation

top radius |

| i4 |

Bottom

Radius

|

Specifies the perforation

bottom radius |

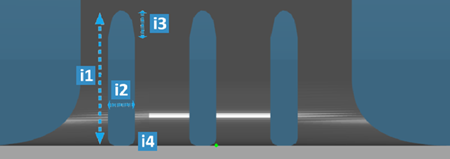

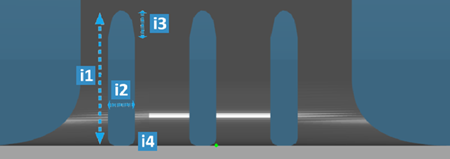

- Ovoid

| Legend |

Parameter |

Definition |

| i1 |

Height

|

Specifies the perforation

height |

| i2 |

Width |

Specifies the perforation

width |

| i3 |

Top

Height

|

Specifies the perforation

top height |

| i4 |

Bottom

Radius

|

Specifies the perforation

bottom radius |

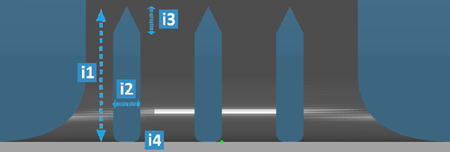

- Triangular

| Legend |

Parameter |

Definition |

| i1 |

Height

|

Specifies the perforation

height |

| i2 |

Width |

Specifies the perforation

width |

| i3 |

Top

Height

|

Specifies the perforation

top height |

| i4 |

Bottom

Radius

|

Specifies the perforation

bottom radius |

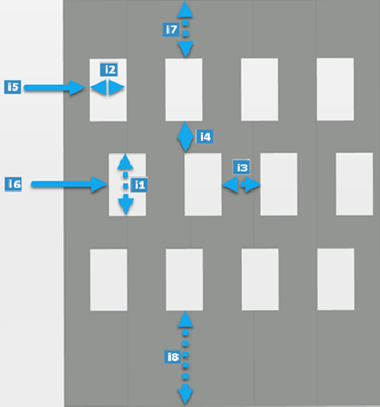

- Spacing Pattern Type

-

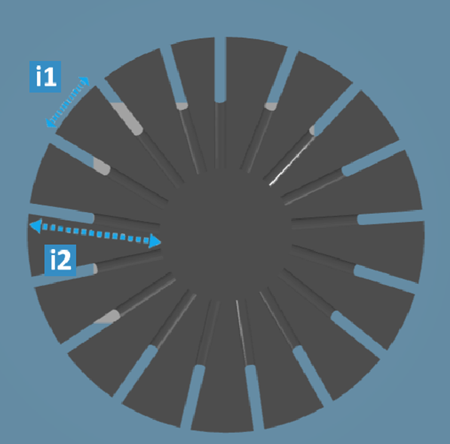

- Curvilinear

| Legend |

Parameter |

Definition |

| i1 |

Step

|

Specifies the spacing between the perforation along the

curve |

| i2 |

Lenght |

Specifies the perforation depth |

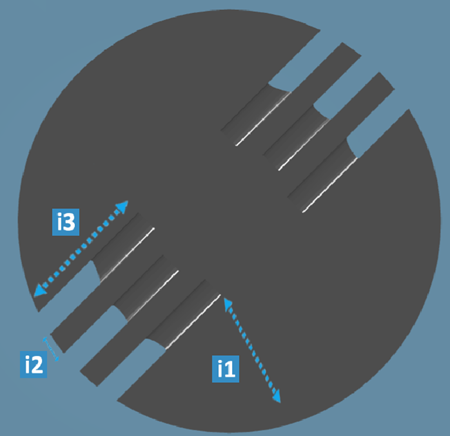

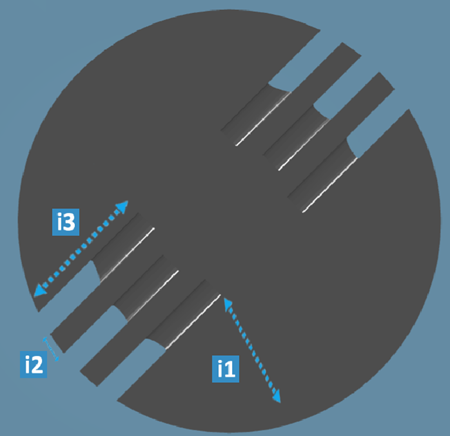

- Mono-directional

Note:

The perforations are

perpendicular to a reference direction (by default

X Ref Axis).

| Legend |

Parameter |

Definition |

| i1 |

Additional Angle

to X Ref axis |

Specifies the angle between X Ref axis and the reference

direction |

| i2 |

Step

|

Specifies the spacing between the perforations along the reference

direction |

| i3 |

Lenght |

Specifies the perforation depth Note:

Unavailable if

Depth Type is set as

Up to

next.

|

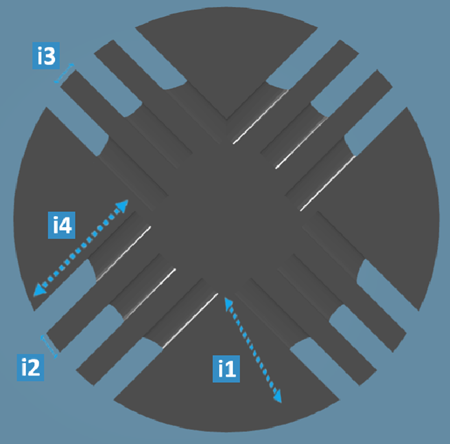

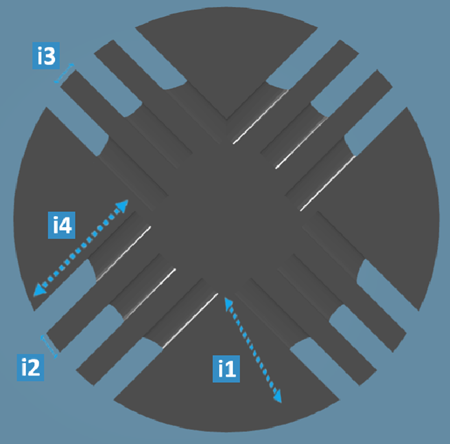

- XY Grid

Note:

The perforations are

perpendicular to a reference direction (by default

X Ref Axis) and along the reference

direction.

| Legend |

Parameter |

Definition |

| i1 |

Additional Angle

to X Ref axis |

Specifies the angle between X Ref axis and the reference

direction |

| i2 |

X

Step

|

Specifies the spacing between the perforations along the reference

direction |

| i3 |

Y

Step |

Specifies the spacing between the perforations along the direction

perpendicular to the reference direction.

|

| i4 |

Lenght |

Specifies the perforation depth Note:

Unavailable if

Depth Type is set as

Up to next.

|

- Depth

-

| Type |

Description |

| Fixed

|

The perforation depth is

limited by a fixed value. |

| Up to

next |

The perforation goes through

the support. Note:

If Spacing pattern

type is defined as

Curvilinear, this is

unavailable.

|

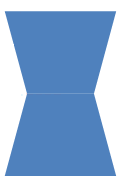

Rules for Generating Anchors

It is possible to define anchors between the supports and part. Anchors are

thinner than supports, allowing you to remove the support structure from the

manufactured part.

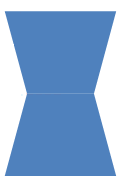

Anchors have a shape similar to the one below:

When using anchors, the part is automatically subdivided into geometric shapes. One

geometry shape corresponds to one anchor. It is possible to customize the geometry

shape associated with one anchor by modifying the value of the Grid

length or Space between anchor points

parameters.

To define anchors, select the With anchors check box in the

dialog box that appears when you select a shape for a support. The following

parameters are available:

The following

parameters are available:

|

Surfaces

Surfaces Edges

Edges  Points of a part

Points of a part  allows you to draw the required support

zone directly on the part in the work area. Note: Free Form

allows you to draw the required support

zone directly on the part in the work area. Note: Free Form is only compatible with the Surface and

Edge zone types.

is only compatible with the Surface and

Edge zone types.  allows you to define a sectioning plane

in the work area. Use the Robot to position the plane. Clicking Sectioning

allows you to define a sectioning plane

in the work area. Use the Robot to position the plane. Clicking Sectioning

again hide the plane and the part

becomes fully visible again.

again hide the plane and the part

becomes fully visible again.

from the

from the

command in the

command in the

in the image above.

in the image above. in the image above.

in the image above.  in the image above.

in the image above.