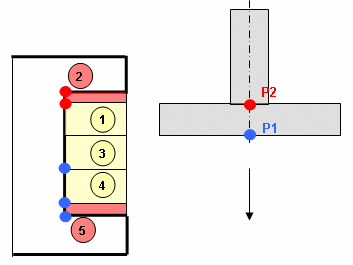

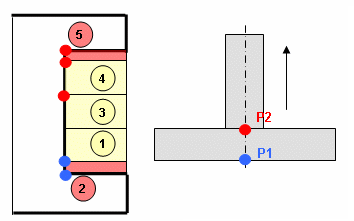

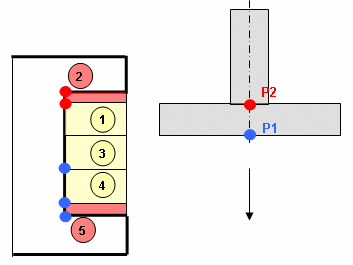

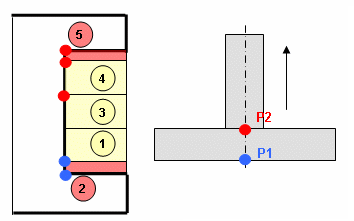

The tool path is computed as follows:

- The roughing pass ordering respects the machining direction definition.

- If a side finish pass is defined, a side finish pass is done for each

roughing level

- If a top and/or bottom finish passes are defined, top and/or bottom

finish passes are done in order to minimize tool motion between levels. For example:

- in top/bottom machining with top and bottom finish passes, top finishing

is done just after the first machining level and just before the second

machining level.

- in bottom/top machining with top and bottom finish passes, bottom finishing

is done just after the first machining level and just before the second

machining level.

- The tool compensation point is taken into account for each pass.

This point is switched automatically during a Return between levels

macro whenever the next level to machine requires a different compensation

point.