Creating All Machinable Features from Geometry

You can create all recognizable machinable features from their geometry.

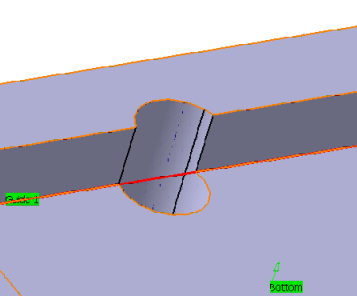

Global Feature Recognition also provides a prismatic machining area corresponding to a complex pocket. The boundary is defined by a hard

boundary only. An imaginary contour at the intersection of hole and slot, is

automatically defined to close the hard contour, but this imaginary contour is shown

only when the hole is recognized by Prismatic Machining Preparation Assistant. In

this way it gives the correct minimum and maximum channel width values for prismatic

machining area.

-

From the Axial

Machining section, select Global Feature

Recognition

.

The Global Feature Recognition dialog box appears.

.

The Global Feature Recognition dialog box appears. -

In the Basic tab, set Selection

Type to Body then select the part in

the work area.

Global Feature Recognition takes the whole body into account.

- Under FeatureFrame, select all the check boxes to search all prismatic machinable feature types in the part.

-

Depending on which features you want to create, proceed as follows:

- To create machinable axial features only, select the Hole check box.

- To create prismatic machining areas only, select all the check boxes except Hole.

- To create all holes included in a tab hole, select the

Enable creation of tab hole components check

box. Note: A tab (or tabulated) hole is more complex than a Part Design hole in that its hole chain (that is, all faces) do not match a Part Design feature. If the check box is not selected, the holes belonging to the tab holes are not created (default behavior).

If the Hole check box is selected, the Only for existing Tech. Result and Only for non existing Tech. Result check boxes become available. - Select Only for existing Tech. Result to create machinable axial features only for holes with technological results.

- Select Only for non existing Tech. Result check box to recognize holes without associated technological results.

-

Select the Advanced tab to specify parameters for

specific processing.

-

Select a face, a line, or an edge in the work area to specify the machining direction.

- The machining axis of the created features is parallel to the machining direction.

- The Create features only in this direction check box becomes available.

-

Optional: After specifying the machining direction,

select the Create features only in this

direction check box.

This is helpful to create features corresponding to the machining direction of a particular machine setup.

-

Optional: Select the Hole / Pocket or

Cutout check box.

Note: Make sure you have selected the appropriate prismatic machinable feature type in the Basic tab (for example, to recognize a hole as a pocket, select the Hole and Complex Pocket check boxes or just the Complex Pocket check box).

- Large diameter holes are created as pockets

- Small diameter intersecting holes are created as holes instead of a single complex pocket.

- Optional: If you have selected Hole in the Basic tab, select the Ignore tapered hole component for hole recognition check box to ignore the fact that the hole type is tapered during feature recognition.

-

Select Include User Parameters in Axial

Features check box to create pattern based on user

parameters (string and integer) for the recognized holes.

Notes:

- As Global Feature Recognition reads the user parameter values from the technological results associated to the holes, it is compulsory to create technological results for all the holes for which you want to create machinable axial features and patterns.

- You can see all the included parameters and their values when double-click the machinable axial features in the Manufacturing View.

-

Select a face, a line, or an edge in the work area to specify the machining direction.

- Select the Axial Filter tab to create machinable axial features.

- Select the Pattern tab to create machining patterns automatically.

-

Click OK to start the feature recognition process.

- Optional: Click Cancel in the progress bar that appears to interrupt the process.

- A dialog box opens and displays statistics about the recognized prismatic machinable features, such as the number of faces, the number of holes found and their types, the number of patterns created, etc.

- All recognized prismatic machinable features are created as Prismatic machining area.x, MAF.x or Pattern Geometry.x as per your request.

- They are visible in the Manufacturing View (Sort by Patterns or Sort by Machining Features).