Experimental research has determined that the quality of the results for a shot peening

process depend mainly on the intensity of the peening. The

Intensity parameter quantifies the amount of energy being

impacted on the surface by the streaming shot. The other process variable to be tracked

during shot peening is the duration of peening impact, which is the Exposure Time at any

point of the surface being peened. This exposure time is directly affected by the

industrial robot motion speed relative to the surface being processed. Peening test

experiments have also established that the increase in intensity of peening is not linear

with the duration of impact. Instead, the behavior is such that for a given peening setup

with increasing exposure time duration, the intensity reaches a particular saturation

level.

The Intensity of a shot peening process is measured and monitored by means of a

standardized type of calibration test called an Almen Test. The Almen Strip

for such a calibration test is made of spring steel with strict tolerances for hardness

and flatness. During the test, the Almen Strip is peened on one side only, and the effect

of the induced compressive stress on one side of the strip results in it becoming very

slightly curved. This deflection Arc Height is correlated to the energy imparted by the

shot and it is measured using an Almen Gauge. The Intensity resulting from a peening

process is measured in units of mm of Almen strip arc height curvature.

The resulting test Almen strip arc height varies according to both the velocity and mass

of the peening shot. Intensity is therefore related directly to the amount of energy

imparted by the stream of shot and absorbed by the strip. The increase in intensity (and

hence the Arc Height in test measurement) is not linear with Exposure Time but curves

towards a saturation limit. Such an Intensity versus Exposure graph is generated by doing

multiple tests of the peening setup with different robot motion speeds. Based on this

graph, the peening Saturation Limit is defined as the point on the curve such that peening

exposure time being doubled results in the arc height or deflection of the Almen strip

increasing only by another 10% or less. Finally, given the above calibration data for a

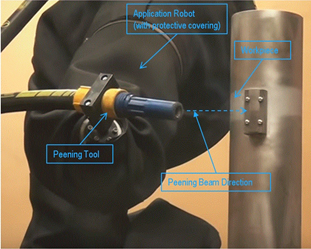

robotic shot peening setup, the actual peening results are a consequence of the industrial

robot program as it follows the complex surface and the effective speed, distance, and

inclination of the robotic peening tool over the course of the duration of peening as it

proceeds.