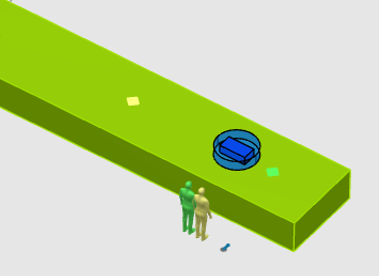

You can define a conveyor as a continuous flow line and play the simulation using

a mobile storage pallet with the mobile storage pallet flowing directly to the conveyor.

A mobile storage is a storage type that you have defined as mobile, which allows it to

be on a conveyor.

Before you begin: Open a scenario with a mobile storage pallet on a conveyor and a buffer

activity.

-

Select a conveyor and click Edit SLA Resource or

Edit Product Flow.

-

In the Processing Mode section of theEdit

dialog box that appears, select the Continuous Flow

Line option to define the conveyor as a continuous flow

line.

Note:

The part accumulation mode is always nonaccumulating for a continuous

flow line, so you must manually ensure appropriate speed and part

spacing on the conveyor.

-

To specify the position of the part on the conveyor during simulation,

right-click a part in the Resource Configuration table,

then click .

You have modified the part position during simulation.

-

Click the Play command on the Compass to begin the simulation.

The continuous flow line simulation plays with the mobile storage

pallet flowing directly to the conveyor. The simulation also shows the

product flows for the parts moving directly to the decision zone.

Note:

During the simulation, you must trigger the operation at the

decision zone when the mobile storage pallet meets the decision zone.

Due to this, the mobile storage pallet must flow directly to the

conveyor during the operation. If there is a worker assigned to the

operation, then the worker must move along with the mobile storage

pallet.

The worker must also meet at the midpoint of the mobile storage pallet on

the moving conveyor. When the pack activity is complete, the part will

be at the corresponding product zone of the mobile storage pallet.

-

Stop the simulation if the operation is not complete before the mobile

storage pallet reaches the end of the conveyor.

-

Resume the simulation when the unpack activity is complete, then route

parts out of the conveyor.

-

Select the buffer activity and click Edit SLA

Resource or Edit Product Flow.

-

In the Edit dialog box that appears, check the

Sequence Mode option to control the production

sequence of machines.

When you define the sequence mode on the buffer activity, the buffer

sequences parts based on the resource level capacity only.

You have defined the conveyor as a continuous flow and simulated the scenario

with a buffer activity.