Add a Create Activity

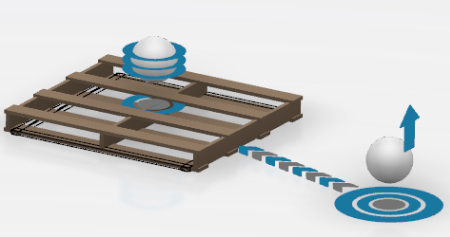

You can add a create activity to an in zone.

-

From the Programming section of the action bar, click Add Create Activity

, and select an in zone. , and select an in zone.

The in zone is highlighted and a context toolbar displays.

-

In the context toolbar, click Add Product(s) to define a Create Activity

and select one or multiple products. and select one or multiple products.

-

Press Esc.

The create activity displays on the in zone, symbolized by an up-arrow.

The selected products are associated to the activity.

Add a Dispatch Activity

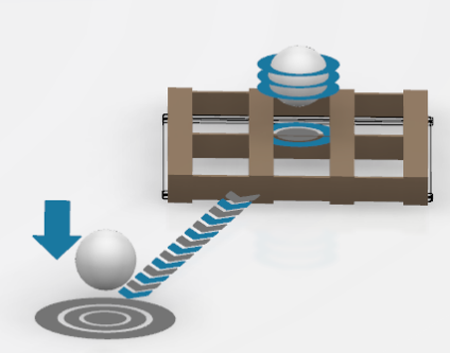

You can add a dispatch activity to an out zone.

-

From the Programming section of the action bar, click Add Dispatch Activity

. .

-

Select an out zone.

The out zone is highlighted and a context toolbar displays.

-

In the context toolbar, click Add Product(s) to define a Dispatch

Activity

and select a product. and select a product.

-

Press Esc.

The dispatch activity displays on the out zone, symbolized by a

down-arrow. The selected product is associated with the activity.

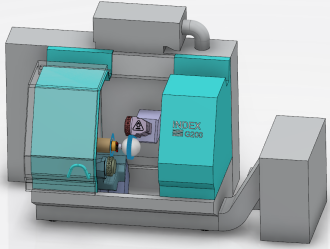

Add a Transform Activity

You can add a transform activity to a resource such as an NC machine, part inside

a pallet, or a mobile storage.

-

From the

Programming section of the action bar, click Add Transform Activity

. .

-

Select a product zone.

-

In the context toolbar, click Add Product(s) to define the Requirement(s) for the

Transform Activity

and select an input product. and select an input product.

-

Click Add Product(s) to define the Output for the Transform

Activity

and select an output product. and select an output product.

-

Press Esc.

The transform activity displays on the product

zone, symbolized by a curved arrow. The selected products are associated

with the activity.

-

Click Simulation Options

at the

right edge of the work area. at the

right edge of the work area.

The Simulation Options dialog box displays.

-

Go to the Flow Simulation

tab and check the Display inputs at design positions at start of

transform activity option.

You have displayed the parts at the design position at the beginning

of the transform activity.

-

Select the product zone with the transform activity and click

Edit SLA Resource to open the

Edit dialog box.

-

Assign or unassign a resource pool by selecting it from the list, then

click Assign or Unassign, then

specify the Quantity of workers.

-

In the Executing Position list, choose the required

home position associated with the resource pools.

You have defined the home position for the Robot and the machine by choosing a position from the list, which applies

during the activity's execution.

-

Select several transform activities in the Resource

Configuration panel, then right-click an activity and select

Create Common Inputs Group

. .

-

Specify if the group is a Transform or an

Assembly type.

-

Select the common part for the input group and the output of the group

execution.

- If you choose Assembly, the command adds aux

parts to the common input.

- If you choose Transform, the command

transforms the common part and the aux part into a new part.

- During simulation, once the common part arrives on the machine, all

the transform activities of the group begin. The overall output is

generated once all the transform activities are completed.

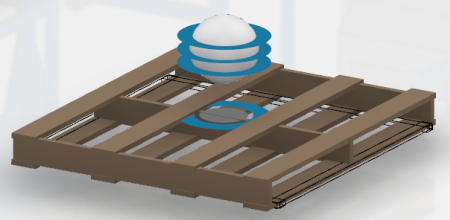

Add a Buffer Activity

You can add a buffer activity to a resource such as a pallet.

-

From the Programming section of the action bar, click Add Buffer Activity

. .

-

Select a product zone.

The product zone is highlighted and a context toolbar displays.

-

In the context toolbar, click Add Product(s) to define a Buffer Activity

and select a product. and select a product.

-

Press Esc.

The buffer activity displays on the product zone, symbolized by a set of

rings.

-

Select the product zone with a buffer activity and click Edit

SLA Resource.

The Edit dialog box displays.

-

In the Waiting Time section, enter the required wait

time value.

You have defined the waiting time for a product before the buffer

reroutes it.

-

Enable Sequence Mode and set Flow Mode

Out to As Per Sequence.

During simulation, parts are routed from the buffer activity as per

the sequence you defined.

Add a Transfer Activity

You can add a transfer activity to a resource such as a conveyor.

Add a Load Activity

You can load products into a machine by adding a load activity to the

machine.

Before you begin: Make sure that the machine has a product zone assigned.

-

From the Programming section of the action bar, click Add Load Activity

. .

-

Select a machine.

- Optional:

If the machine has several product zones, select the product zone to which

you want to assign the activity.

-

Assign or unassign a resource pool by selecting it from the list, then

click Assign or Unassign, then

specify the Quantity of workers.

-

Select the product you want to load.

- Optional: To edit the activity:

- Select the machine and click

Edit the SLA Resource Behavior and Activities

. . -

In the dialog box, modify the parameters as required.

Add an Unload Activity

You can unload products from a machine by adding an unload activity to the

machine.

Before you begin: Make sure that the machine has a product zone assigned.

-

From the Programming section of the action bar, click Add Unload Activity

. .

-

Select a machine.

- Optional:

If the machine has several product zones, select the product zone to which

you want to assign the activity.

-

Assign or unassign a resource pool by selecting it from the list, then

click Assign or Unassign, then

specify the Quantity of workers.

-

Select the product you want to unload.

- Optional: To edit the activity:

- Select the machine and click

Edit the SLA Resource Behavior and Activities

. . -

In the dialog box, modify the parameters as required.

- Optional:

You can also edit the activity when you double-click the unload activity in

the Resource Configuration panel.

- Optional:

In the Edit dialog box that displays, activate the

Unload On Request to unload the activity on

request.

Notes:

- You can also add, create, dispatch, transform, buffer, and transfer activities on zones

that already have an activity assigned. Select a zone and, in the context toolbar that displays, select the activity to add.

- You can add a load or unload activity to a machine that is part of a

product flow. In this case, you can use the product associated with the

product flow can as an input product for the load activity, or output

product for the unload activity.

- To delete an activity, right-click the activity and select

Delete.

- The unload activity is only executed when there is a request for a part

in the downstream resources machine during simulation. If there is no

request, then the unload activity is not executed and the resource is

blocked while it goes into the wait for output state. Once there is a

request for the part, the unload activity is triggered and the machine

is un-blocked.

Add a Generic Activity

You can add a generic activity to an NC machine using the Resource

Configuration panel. Generic activities include actions such as

auto-eject, rotate, open/close door, and so on.

-

Click Resource Configuration

from

the Programming section of the action bar. from

the Programming section of the action bar.

Note:

You can also add a generic activity with the Add Generic

Activity

command in the Programming section of the action bar.

command in the Programming section of the action bar.

-

In the Resource Configuration panel that displays,

right-click a machine.

-

Click Add Generic Activity

from

the context menu. from

the context menu.

-

In the dialog box that displays, enter a name, duration, precedence, and

position.

- Optional:

If the machine has several product zones, select the product zone to which

you want to assign the activity from the list

Products. Or you can select

to add a new

product zone. to add a new

product zone.

-

Assign or unassign a resource pool by selecting it from the list, then

click Assign or Unassign, then

specify the Quantity of workers.

-

Click OK.

-

Click the product zone with the generic activity and click Edit

SLA Resource.

The Edit dialog box displays.

-

In the Executing Position list, choose the required

home position associated with the resource pools.

You have defined the home position for the Robot and the machine by choosing a position from the list, which applies at

the end of the activity.

- Optional:

Define a value in the Rejection Rate section and

enable the Quality Check option.

Note:

The value you enter determines which part is marked for rework or

good.

The generic activity displays under the Generic Activities tree in

the Resource Configuration panel.

Create an Activity by Dragging

You can create an activity using dragging in the Resource

Configuration panel. This activity is mainly for Planning

Integration.

-

From the Programming section of the action bar, click Resource Configuration

. .

-

In the Resource Configuration panel that displays,

drag the required operation from the tree to the required destination in the

panel.

The activity has the same name as the operation from the tree.

Add a Pack Activity

You can add a pack activity to a resource such as a pallet.

Before you begin: Create a buffer resource to use as a pallet. This buffer contains the buffer

activities for all the products that the pallet needs to pack on the conveyor.

-

Click Define Mobile Storage

in the Setup section of the

action bar then select the buffer resource. in the Setup section of the

action bar then select the buffer resource.

Note:

You can also add a pack activity with the Add Pack

Activity

command in the

Programming section of the action bar. command in the

Programming section of the action bar.

You have defined the buffer resource as a mobile storage.

-

Click the product zone of the buffer resource.

This product zone is now the starting point of the selected mobile

storage.

-

Click Resource Configuration

in the Programming section

of the action bar. in the Programming section

of the action bar.

-

In the Resource Configuration panel that displays,

right-click a product zone.

-

In the context toolbar that displays, click Add Pack Activity

. .

-

Click a pallet resource from the tree or the work area, then select the products that need to be packed on the pallet

resource.

-

Optional: Create multiple instances of the same pallet and

declare them as a mobile storage with Define Mobile

Storage

. .

You have defined one pack activity using a pallet. This supports

multiple instances of the same pallet without redefining respective pack

activities. During simulation, all instances of the pallet execute using the

same pack activity as reference.

-

Double-click the pack activity in the Resource

Configuration panel to edit it.

-

In the Edit dialog box, click Add context

for pack

under Context for Pack

Activity. under Context for Pack

Activity.

-

In the Context for Pack Activity panel, select context

from the suggested context, then click OK.

The context is updated in the Edit dialog box

and all parts appear at the correct location based on the context you

specified for the pack activity during simulation.

You have added the pack activity. During simulation, axillary

parts are accepted only after the pallet has arrived. Note:

You can edit the pack

activity by double-clicking the activity in the Resource

Configuration panel.

Add an Unpack Activity

You can add an unpack activity to a resource such as a pallet.

Before you begin: Create a buffer resource to use as a pallet. This buffer contains the buffer

activities for all the products that the pallet needs to unpack on the conveyor.

-

Click Define Mobile Storage

in the Setup section of the

action bar then select the buffer resource. in the Setup section of the

action bar then select the buffer resource.

Note:

You can also add an unpack activity with Add Unpack

Activity

in the

Programming section of the action bar. in the

Programming section of the action bar.

You have defined the buffer resource as a mobile storage.

-

Click the product zone of the buffer resource.

This product zone is now the starting point of the selected mobile

storage.

-

From the Programming section of the action bar, click Resource Configuration

. .

-

In the Resource Configuration panel that displays,

right-click a product zone.

-

In the context toolbar that displays, click Add Unpack Activity

. .

-

Click a pallet resource from the tree or the main 3D, then select the

products that you need to unpack on the pallet resource.

-

To edit the activity, double-click the activity in the Resource

Configuration panel.

-

Optional: Create multiple instances of the same pallet and

declare them as a mobile storage with Define Mobile

Storage

. .

You have defined one unpack activity using a pallet. This supports

multiple instances of the same pallet without redefining respective unpack

activities. During simulation, all instances of the pallet execute using the

same unpack activity as reference.

- Optional:

In the Edit dialog box that displays, activate the

Unload On Request to unload the activity on

request.

You have added the unpack activity. During simulation, axillary

parts are routed before routing the pallet. Note:

The unpack activity is

only executed when there is a request for a part in the downstream resources

machine during simulation. If there is no request, then the unpack activity is

not executed and the resource is blocked while it goes into the wait for output

state. Once there is a request for the part, the unpack activity is triggered

and the machine is un-blocked.

Duplicate a Mobile Storage

You can automatically create manual storages using a reference mobile

storage.

-

From the Setup section of the action bar, click Duplicate Manual Storage

. .

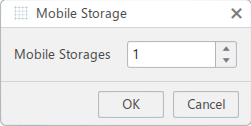

The Mobile Storage dialog box

displays.

-

Select the quantity of mobile storages to create and click

OK.

-

Select the mobile storage to duplicate, then select the parent of the newly

created mobile storage.

-

Select a product zone to be used as the initial location.

The new mobile storages are created under the selected

parent.

|