Generate 2D Details for Electrical Devices, Equipment and Supports

You can use the GVS to customize the drawing of flattened data with 2D

details for devices, equipment and supports.

By default, 2D detail generation is

based on device, equipment, or support part number. A device contains an external reference attribute:

- If it is not valuated, the part number of the device is used for the 2D detail.

- If it is valuated, a 2D detail with the same name is searched in the catalog or library

mentioned in the GVS and is instantiated in the drawing.

Supports and equipment do not have any external reference attribute. You can create

an External Reference Knowledge parameter to use the same 2D

detail for several references of support or equipment:

- If the parameter is not valuated, or does not exist, the part number of the

support or equipment is chosen by default and you need to create as many 2D

details as the number of support or equipment references.

- If the parameter is valuated, the 2D detail with a name corresponding to

the parameter's value, external reference, is used.

To create an External Reference parameter for a support,

follow the steps below:

-

Select a support.

-

From the Compass, click Engineering Rules Capture.

-

Click Parameter Set

from

the Engineer Rules Capture section. from

the Engineer Rules Capture section.

The Knowledge Engineering Specification

Physical dialog box appears.

-

Enter a representation name (Support) and click OK.

A Support node appears in the tree, with a

Parameters sub-component:

-

Select Parameters in the tree and click Parameters

Explorer

in the Engineer Rules Capture section.

in the Engineer Rules Capture section.

-

In the New Parameter of Type list, select the

String type, then in the opposite field

(With), select Single

Value.

-

Click New Parameter of Type and give a

Local Name: External reference.

-

In the Parameter > Value, enter:

2DDetailName.

-

Click OK.

The external reference parameter with the 2D detail name is visible

in the tree.

Generate 2D Details for Protective Coverings and its Ends

You can use the GVS to customize the drawing of flattened data with 2D

details for the protection covering and its ends. By default,

- 2D detail generation for ends is based on the external reference attribute

- 2D detail generation for protective covering is based on the exact name of the

reference part.

-

To generate the 2D details for protection covering ends:

-

Under the electrical GVS parameters, select

Yes from the

Generation list, available in and then specify the catalog name for 2D details

instantiation.

Note:

You can set generation preferences for all the available

protection types.

-

Specify external reference attribute string (same as the name of

the one specified in the catalog) that needs to be instantiated.

The 2D details at the ends of the protective covering are

instantiated in the generated 2D data. Note:

The same 2D detail is

used for both ends of the protective covering. Thus, when

defining the detail, the administrator must respect the detail

symmetry about the x-axis.

The center of the detail is placed on the end point of the

protective covering and the OX axis of the detail follows the

tangency of the curve at the previous point. When generating the

drawing, 2D details are scaled according to the layer of

protective covering to which they are applied.

-

To generate the 2D details for protection covering, set the GVS attribute

to Yes from the Generation

list, available in .

Note:

You can set generation preferences for all the available protection

types.

The element from the catalog/library named identical to the reference part name is

instantiated.

Generate 2D Details at Harness Junctions

You can use the GVS to customize the drawing with symbols representing

the harness junctions.

-

In your GVS, select .

-

Set the GVS parameters:

-

Under the Generation node, select

Yes to activate the customization

functionality.

-

Under the CatalogName node, enter the name

of a catalog/library and chapter/class.

-

Under the SymbolName node, enter the name of

the symbol to represent the junctions.

Note:

When the catalog name or symbol name is not found, the customization

is not applied even if the Generation is set to

Yes.

For more information, see Electrical

Manufacturing Preparation Parameters.

-

Click OK to validate.

When using the Front View

command, the selected symbol is displayed at every harness junction.

Notes:

- For broken junctions due to loops, the symbol is displayed at

one of the broken extremities.

- If the harness is modified leading to junctions creation or

modification, use the Update

command to refresh the drawing.

command to refresh the drawing.

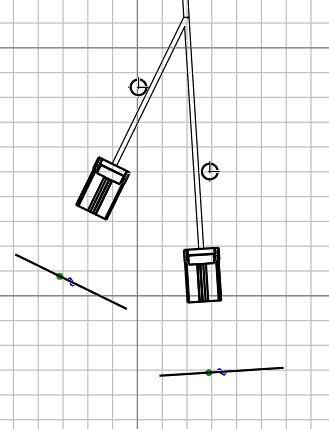

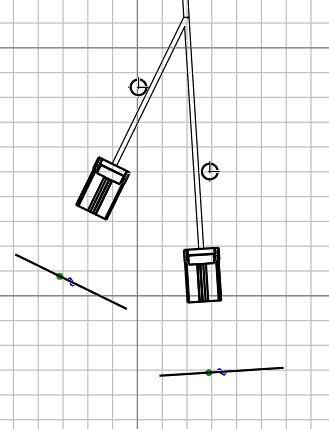

Generate 2D Details for Support Section Views

You can use the GVS to customize the drawing of flattened data with 2D

details for support section views. By default, one 2D detail per support section is

generated. Details are positioned on the drawing on a grid. The details of support

sections are oriented according to the orientation of the support in the 3D view.

-

Select .

-

In the Standard Definition dialog box, expand the

EquipmentAndSystems node.

-

Select Support > Representation > SectionOfSupport >

Generation node and, in the

Generation list, select

Yes to generate 2D details for support section

views.

Node supports are identified by a letter and corresponding details

are identified using the same identifier plus a prefix, if desired.  In this example, the arrow on the right side is a 2D detail which is

superposed on the 3D projection of the support. The symbols used in the

drawing view can be:

- Images from the catalog if you filled the External

Reference attribute in your support with a knowledge

parameter

- A symbol named after the support part number

The automatic generation leads to the creation of following elements:

For more information, see About Customizing a Drawing View.

Generate 2D Details for Cutting Information

You can add a cutting line associated with a scissor symbol to your drawing.

These features set in the GVS show where to cut a conductor on the formboard.

The cutting line is defined by a symbol and an offset value separating the device

extremity from the cutting line.

Before you begin: In Data Setup, assign your cutting line symbol in the

Drawing catalogs or the Drawing

libraries resource.

-

In your GVS, select .

-

Set the parameters:

-

Under Generation, select

Yes.

-

Under CatalogName, enter the name of the

catalog or library in which the symbol is set.

-

Under SymbolName, enter the name of the

symbol representing the cutting line.

Note:

When the catalog name or symbol name is not found, the customization

is not applied even if the Generation is set to

Yes.

For more information, see Electrical

Manufacturing Preparation Parameters.

-

To define the offset value of the cutting line, do either of the following:

-

Generate the drawing either using the Documentation

command or the Front View command.

After the generation, the selected symbol is displayed at the extremity of every

device assembly.

Note:

The cutting line must be drawn perpendicular to the axis of the

branch connected to the device assembly and align with the origin of the y-axis.

|