About Previous Part Position | ||||

|

| |||

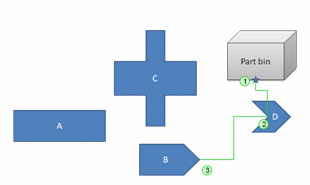

Part Bin

A part bin is a storage resource where the parts to assemble are stored before assembly operation. It is linked to an operation as a "with" resource.

The part bin is associated to an item (or manufacturing assembly) by means of a capable resource link. This link can be used to specify the storage resource where a specific item is stored. It can be created in Manufactured Item Definition.

The item is implemented by an operation and implements one or several products.

End Position and Start Position

Tracks are created in order to assemble a product. You can work in two different ways.

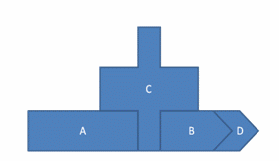

Starting from the final mounted product (see figure below), you can create unmounting tracks and then reverse them.

In this case, you select the part position in part bin or the previous part position at the end of the track creation and this point is used as the end point of the track (see figure below).

Then after reversing the track, the selected position becomes the start position of the track (see figure below).

Working with an exploded view (see figure below), you can create the mounting tracks directly.

As the first point is created by default at the part position, you first select the part position in part bin or the previous part position and then reorder it to have it as the first point. The selected point is used as the start position of the track (see figure below).

Part Position in Part Bin

A track can move a single manufacturing assembly. It can also move several used resources.

If a part bin is defined on the operation, and if it is associated to the manufacturing assembly moved by the track, then the part position in the part bin is proposed as start point.

It is possible to associate a capable resource to a manufacturing assembly, and this link can used to determine if a part bin is associated to a manufacturing assembly.

If the relative position of the manufacturing assembly to the capable resource is taken into account, then this position is used. If this position is not defined by the user, the position of the resource itself (part bin axis system) is taken.

Selection of a part position in a part bin is not possible in the following cases:

- If no part bin is defined as a storage resource, and if the part moved by the track has not been moved by another track in a previous operation, no specific point can be selected.

- If a part bin is defined on an operation, but if it is not associated to the part moved by the track, and if the part moved by the track has not been moved by another track in a previous operation, then no selectable point is proposed.

- If several items are associated to the track, there are potentially several part bins associated to the items. As all the manufacturing assemblies are moved with the same track, these part bin positions are not coherent and are not proposed.

Previous Part Position

A track can move a single manufacturing assembly. It can also move several used resources.

The previous operations are the operation that are completed before the current operation starts.

If the manufacturing assembly moved by the track has already been moved by another track in a previous operation, the last position of the previous operation is proposed as a selectable point.

If a defined position is set on this operation, it is taken into account by the track.

If the manufacturing assembly moved by the track has already been moved by a defined position in a previous operation (and if there is no track on that operation), then the defined position is proposed as a selectable point.

If no track and no defined position is set on the previous operation, the initial product position is proposed as a selectable point.

If several items are associated to the track, there would be potentially several previous positions associated to the items. As all the manufacturing assemblies are moved with the same track, these part positions are not coherent and are not proposed.