Assembly Evaluation | |||||||||

|

| ||||||||

Assembly Evaluation uses the design review environment of Manufacturing Planning to handle a wide range of products from consumer goods to very large automotive or aerospace projects as well as plants, ships and heavy machinery. You work in the manufacturing simulation environment to define and simulate assembly and disassembly procedures, which enables you to validate product assembly and maintenance at the design stage.

Assembly Evaluation provides the following capabilities:

- Interactive assembly path creation and editing

- Product buildup, operation by operation, in resources context

- Identification of operations by selecting manufacturing assemblies in 3D

- Definition of probe points for analysis during simulation

- Definition of assembly simulation scenarios

- Interference detection and checks during simulation

- Choreographed simulations

- Management of assembly sequences with Gantt editor

- Creation of excitation referencing operations in manufacturing simulation scenarios

- Generation of results of a manufacturing scenario in a simulation context

- Generation of animations of assembly simulations

- Swept volume analysis during simulation replay

- Automatic generation of an exploded assembly state

Both the designer and the planner can use Assembly Evaluation to accomplish a number of workflows such as assembly feasibility studies, process validation, and planning authoring and validation.

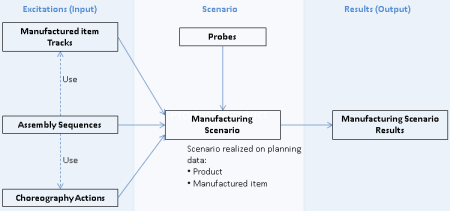

Designer Workflow for Early Assembly Feasibility

The figure below illustrates the general workflow that the designer can follow for early

assembly feasibility using the Simulation environment.

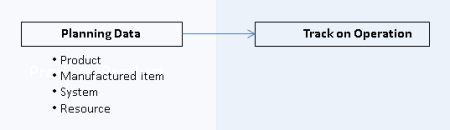

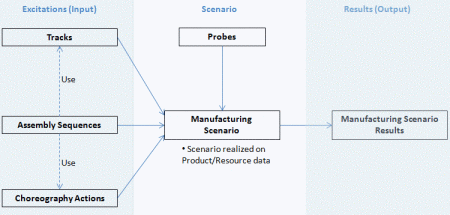

Planner Workflow for Early Process Validation

The figure below illustrates the general workflow that the planner can follow for early

process validation using the Simulation environment.