3DEXPERIENCE to V5 Data Import Table

This table describes the export effect on mechanism entities that can be translated using the Downward Compatibility tool. See File Coexistence and Migration User's Guide for more information.

| 3DEXPERIENCE Data Type | Export Effect |

|---|---|

| Mechanisms | |

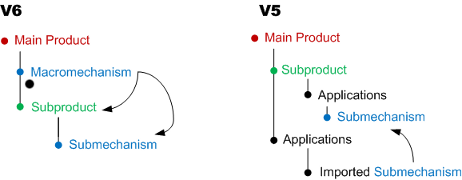

| Mechanism representation under a root product (not flexible) | Exported as mechanism. A mechanism is created under the Applications node. |

| Partially defined mechanism | Exported as mechanism but cannot be simulated in V5 |

| Submechanism | Exported as mechanism |

| Macro mechanism | Not supported except a macro mechanism that assembles only one mechanism. |

| Commands | |

| Command | Partially supported as some joints cannot be assigned commands in V5. Potential orientation issues. See Export Exceptions or Limitations for more information about commands. |

| Engineering Connections | Partially supported. Exported as V5 joints; V5 Assembly constraints are not created for geometry combinations that cannot be selected. See 3DEXPERIENCE Engineering Connections vs V5 Assembly Constraints for more information. |

| Rigid | Exported as rigid joint

All supports are permitted. However, the Fix Together relatively constraint is handled as a simple Fix Together in V5. The Fix Together relatively constraint does not exist in a V5 rigid joint. |

| Prismatic | Exported as prismatic joint, except if the 3DEXPERIENCE engineering connection includes coincidence constraints and edge/line elements as supports. |

| Revolute | Exported as revolute joint, except in the two following configurations:

|

| Spherical | Partially supported. Exported as spherical joint if the spherical engineering connection includes a coincidence constraint and two points as supports. The curve as support is not supported. |

| Cylindrical | Exported as cylindrical joint. See Export Exceptions or Limitations for limitations on this type of joint. |

| Planar |

Partially supported. Exported as planar joint, except if the 3DEXPERIENCE engineering connection includes an offset constraint and two face/plane elements as supports. |

| U Joint | Not supported |

| Point Curve | Exported as point curve joint. |

| Point Surface | Exported as point surface joint |

| Roll Curve | Exported as roll curve joint. A 3DEXPERIENCE command assigned to a Roll Curve is exported in V5. If there are two commands assigned to a 3DEXPERIENCE Roll Curve joint, only one command is created in V5. |

| Slide Curve | Exported as slide curve joint. Assigning a command to a slide curve is not permitted in V5. Thus, if a command is assigned to a slide curve, it is not exported to V5. |

| Compound Engineering Connections | Partially supported. |

| Gear | Exported as gear joint See Export Exceptions or Limitations for limitations on this type of joint. |

| Rack | Exported as rack joint See Export Exceptions or Limitations for limitations on this type of joint. |

| Cable | Exported as cable See Export Exceptions or Limitations for limitations on this type of joint. |

| Screw | Exported as a screw joint |

| Fixed Parts | |

| Fixed Part | Exported as fixed part. All supports are permitted. However the fix in space constraint will be handled as simple Fix as it does not exist for a V5 rigid joint. |

| Dressup | |

| Dressup | Exported as a dressup |