Opening the Process Gantt

The Process Gantt chart is opened by selecting the Process Gantt

command, then selecting either the root system or a child system under the root system.

Multi-selection is not available. Only one system and its children are displayed in the Process

Gantt.

If a child system is selected:

- The constraints between

operations are taken into account even if they are

not displayed in the Gantt scope.

- The product flow is taken into account even if it is outside what

is displayed in the Gantt scope.

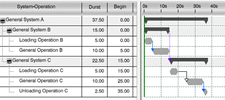

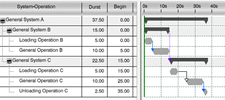

Columns in the Process Gantt

The columns of the Process Gantt chart display information about systems, operations,

parts, fasteners, and resources. Any of the columns (except

System-Operation) can be hidden/shown by right-clicking in

the header area and clearing /selecting any of the column check box options.

The columns in this Gantt chart are as follows:

- System-Operation: Displays a tree view of

the systems and operations.

- Duration: Difference between the start and

end time.

- Begin Time: Start time of an operation.

- End Time: End time of an operation.

- Associated Parts: Instance names of the

assigned parts of an operation. Parts may be displayed as a list with a

separator

(,).

- Type of Time: Estimated, simulated, or

analyzed time of an operation.

- Utilization: Percentage of time for which a

resource is used.

- Value Added: The

value added is an optional attribute that can

be defined in each operation of the system. This value is shown for each

operation, and the average value of all operations is shown for the system. For

more information, see

Value Added Information.

- Number of Fasteners: Displays the number of

assigned fasteners for operation and resources. The first number on the

resource indicates the number of fasteners assigned directly to this resources

behavior. The number in brackets is the sum of the fasteners assigned to the

resources direct behavior and all fasteners assigned to all child behaviors.

- Number of Spots: Displays the number

fastener spots. See

Time Bar for Point Fastening Operations in the Gantt Chart

- Executing Resource: The working resource

assigned to the operation.

- Localization Resource: The organizational

resource assigned to the operation.

- Used Resource(s): The not working resources

assigned to the operation.

- Resource used for positioning: The resource

used for parts positioning for a given operation.

To hide/show any of the columns (except

System-Operation), right-click in the column

header area and deselect/select any of the column check box options.

To change the column size, place your cursor over the edge of the

column. The cursor changes to arrow shape. Move the cursor left or right to

change the column size.

To move a column, select the column. The cursor changes to hand shape.

Move the selected column to left or right as required.

You can use the

Customize Column(s) contextual command to

customize the columns of the Gantt chart with operation, system, and resource

attributes or any new customized attributes.

Tree Expansion

A set of contextual commands is available for expanding and

collapsing the tree in the Gantt chart.

When you right-click any row of the Gantt chart, the following commands

are available in the

Tree Expansion contextual menu:

- Expand First Level: Displays the first level

child row.

- Expand Second Level: Displays the first and

second level child rows.

- Expand All Levels: Displays all the child

levels of the selected row.

- Collapse All: Collapses the row and hides all

its child rows.

- Expand Selection: Displays a

Specification depth dialog box where you can

specify a tree depth for the expansion. You can select one of the available

depth levels (1 to 5) or all levels, or key in a positive number.

Cycle Time Display

The cycle time of systems is displayed in the Process Gantt chart.

Cycle time is displayed by two vertical green bars. They appear if

the system is a leaf system and has operations. The cycle bars stretch from the

top of the system row to the bottom of its last operation row.

If the leaf system has a zero cycle time, only the first bar is

displayed.

Flow View and System View

A Flow view and a System view are available in Process Gantt chart.

- Flow View: This view displays the flow

between systems. It takes into account the full product flow and

time constraints between operations. You can use

this view to display the product flow according to the cycle time.

- System View: This view shifts every system

instance at zero begin time. All systems are seen in parallel.

To switch from one view to the other, right-click the root object of

the Gantt chart and select either

Flow View or

System View in the context menu.

The Flow View / System View is managed for all open Process Gantt charts.

Operation Creation

An operation can be created under a system or under another operation in the Process

Gantt chart.

This is done as follows:

- Select the command of the required operation type.

- Select a system in the Gantt chart or any of its operations (parent

of the new operation).

- Enter its name in the pop-up that appears.

The new operation is then displayed under the system after the last

operation (if a system was selected) or under the operation, if an operation

was selected.

It is also possible to copy, paste, and delete operations in the Process Gantt chart. The Gantt

chart is updated after the copy, paste, or delete.

Operation and System Reordering

Operations and systems can be reordered in the Process Gantt chart.

To reorder operations and systems, drag and drop a row (system or

operation) on another one. The

tree

is also updated after the drag and drop.

Multi-Selection is not available. Only child nodes belonging to the same parent can be

reordered in the Process Gantt chart.

Product Flow and Constraint Creation

Product flows and time constraints can be created in the Process Gantt chart by

dragging and dropping systems/operations and using contextual commands.

The following drag and drop capabilities are possible in the Gantt chart:

- From a system to another system.

- From an operation to another operation.

- From a system to another operation.

- From an operation to another system.

In each case, a product flow is created.

If the drag and drop of a system or an operation to another system is done with the

Ctrl key pressed, a context toolbar will appear with the following commands:

- Create Product Flow

to create a product flow between the system or

operation and the other system. to create a product flow between the system or

operation and the other system.

- Move to System

to

move the system or operation to the other system. to

move the system or operation to the other system.

If the drag and drop of a system to an operation is done with the Ctrl

key pressed, a context toolbar will appear with the following command:

- Create Product Flow

to create a product flow between the system and the

operation. to create a product flow between the system and the

operation.

If the drag and drop of an operation to another operation is done with the

Ctrl key pressed, a context toolbar will appear with the following commands:

- Create Product Flow

to create a product flow between the two

operations. to create a product flow between the two

operations.

- Create Precedence Link

to create a precedence constraint between the two

operations. to create a precedence constraint between the two

operations.

- Create Start-Start Link

to

create a start -start synchronization link between the two operations. Both

operations will start at the same time. to

create a start -start synchronization link between the two operations. Both

operations will start at the same time.

- Create End-End Link

to create an

end-end synchronization link between the two operations. Both operations

will end at the same time. to create an

end-end synchronization link between the two operations. Both operations

will end at the same time.

- Create End-Start Link

to create

an end-start synchronization link between the two operations. You can

specify a delay between the end of one operation and the start of the other. to create

an end-start synchronization link between the two operations. You can

specify a delay between the end of one operation and the start of the other.

- Move Operation

to

move the operation under another operation. The dragged operation becomes

the child of the other operation. to

move the operation under another operation. The dragged operation becomes

the child of the other operation.

For more information, see

Creating Time Constraint Links Between Operations.

Note:

You can access the Constraint Properties panel to edit

time constraints and manage product flows by right-clicking the arrow, then by

clicking Constraint Properties in the context menu.

in the context menu.

Operation Colors

In the Process Gantt chart, colors can be assigned to systems using the

Color in Gantt View contextual command.

In the context menu, the following commands are available:

- Color by Resource: when activated, operations are

colored according to their implementing resource in the Process Gantt chart.

- Default Colors: when activated, the default color is

applied to operations.

Specifying Scale Units

To specify the scale units of the Process Gantt chart, right-click the title bar

showing the time units and select Set Scale Units.

The dialog box that appears allows you to specify the time unit

(seconds, minutes, and so on), the zoom, and the scale to be applied to the

Gantt chart. A preview allows you to try out any entered values before

accepting them.

Modification of an Operation Duration

In the Process Gantt chart, time can be edited if it concerns an operation (and not a

system) which has no child and it is displayed in estimated time.

The estimated time is the only time that can be modified manually.

Simulated and analyzed times are deduced, so they cannot be modified by

defining a value.

To modify the estimated duration of an operation, do one of the

following:

- Right-click the operation, select

Properties then modify the estimated time

value.

- Double-click the

Duration column and modify the value in the

pop-up that appears.

- Double-click the

End Time column and modify the value in the

pop-up that appears.

- Increase the length of the bar representing the operation.

- Double-click the bar representing the operation. A Properties dialog

box appears to let you modify the duration as well as the name of the operation.

Note:

The operation must not have any children. An operation that has

children is like a system: its duration is the sum of all the durations of

its children.

When an operation duration is 0, the operation is

represented by a red symbol.

Note:

You cannot edit a begin time for an operation or a system. Begin

times are deduced by solving the constraints specified.

Value Added Information

The

value added is an optional attribute that can be

specified on each operation of the system. This value is shown for each

operation, and the average value of all operations is shown for the system.

Value added of an operation is an estimate of

how much time that the operation is used for assembly. It is expressed as a

percentage. If no time of the operation is spent on assembly, the

value added can be specified as 0%.

Value added can be used on an operation that

has its time mode defined as Estimated time or Analyzed time. For

value added based on Estimated time, the value

is defined in the operation's

Properties dialog box. For

value added based on Analyzed time, the value is

defined using

Edit Time Analysis. See the

Time-Motion Study

User's Guide for more information.

Sometimes operations have time modes defined as Simulated time or Work

instruction. In this case, the

value added is the percentage defined in

Value Added Ratio on Estimated Time in the

Properties dialog box.

Note:

This information is only displayed in the Gantt chart when the Display value

added ration on system option is selected in

.

You can display a value added categories bar on top of the system cycle

bar. The value added categories are defined on the time

analysis of an operation. You can specify the color of each category in

(for example, green for value added, red for

nonvalue added, and so on). The total value for each

category is computed for all the operations in the system. Note:

This information is

only displayed when the Display value added categories from Time

Analysis on system option is selected in the

.

This option also enables a value added

categories bar to be displayed in the Resource

Balancing panel.

Time Bar for Point Fastening Operations in the Gantt

Chart

The length of the time bar for a Point Fastening operation

depends if it is related to an item with fasteners or fastener

groups linked to it or not.

Two fastener models are supported in

Process Planning

and

Fastener Planning:

the fastener model and the fastener group model.

Both fastener models handle "spots" that define the position of fasteners. A spot is where a

fastening action is done, which is important to describe the Point Fastening operation.

- In the fastener model, there is one spot per fastener.

- In the fastener group model, there can be one of more spots per fastener.

Note:

Fastener groups can no longer be created, but existing fastener

groups are supported.

The length of the time bar for a Point Fastening operation is as

follows:

|