Use Clash Detection

You can quickly compute impacts by detecting clashes between

visible components.

Notes:

- Assembly impacts cannot be created if linked to a representation that is not loaded in the

context:

- The line in Impact Result is disabled.

- A message is displayed.

- You can improve performances by deactivating Technological

Results, either from the

Preferences

or from the

context menu

of the

tree.

-

From the Mold Design section of the action bar, click Components

Impacts

and

select the impacting products containing Assembly Features. and

select the impacting products containing Assembly Features.

- Structured components, non-Tooling components and non-Tooling Assembly Features are supported.

- Only impacted representations found under the UI Activated product

are taken into account.

- When required, select multiple occurrences of an impacting product

before starting Impacts.

-

Expand Options and select Preselect

shapes impacted by clash detection.

The number of impacting products and impact result are displayed.

The impacts are computed from the automatic detection of clashes between

visible elements.

Use Clash Detection with Additional Manual Edition

You can manually enhance the automatic clash detection described

above.

-

Start as described above.

-

Expand Impacting Products to access the table for

editing.

The table lists the Assembly Features, one per line.

- From left to right, each line is made of a check box, the name of

the impacting product, the PLM type of the product, the name of the

impacting element, and the type of impact.

- By default, all the check boxes are selected.

-

Select additional impacting products.

Select Impacting Products is selected by

default.

- They are added to the table, with their

Assembly Features.

- Their check boxes are selected.

- Corresponding Assembly Impacts are added to

Impact Result, with their check boxes

selected.

-

Place the pointer over the name of an impacting product.

The complete path is displayed.

-

Select

Select Impacted Representation check box and

select representations to add.

The

Impact Result table is updated.

-

Click the arrow in one column header to filter the impacting products

respectively by name, PLM type, impacting element or type. The header

expands.

-

Either select the check box corresponding to your choice.

-

Or enter a text (for example a prefix).

The filter applies to all lines, with a selected or cleared check box.

Only the result of the filtering is listed in Impacting

Products.

-

Expand Impact Result to access the table for

editing.

- This table lists possible Assembly Impacts, one per line.

- From left to right, each line is made of a check box, the name of

the impacted product, that of the impacted representation, the name

of the impacting product and that of the impacting element.

- Filtering, selection by check box or pointer works as described

above.

- Only Assembly Impacts with a selected check box are taken into

account when computing impacts.

Use Only Manual Selection

You can skip the automatic detection of clashes and add impacted

representations manually.

-

From the Mold Design section of the action bar, click Components

Impacts

and

select the impacting products containing Assembly Features. and

select the impacting products containing Assembly Features.

-

Make sure that Preselect shapes impacted by clash

detection is cleared.

Only the impacting products are listed. The Impact

Result table is empty.

-

Add impacted representations as explained above.

You can select

- A 3D Shape Representation from the 3D area.

- A 3D Shape Representation, or a 3D Part, or a Product with one

single representation.

-

Filter, select by check box or pointer as explained above.

Define Clash Detection Options

You can control how the clash detection works.

-

Expand Options.

By default, Process also invisible

representations is cleared. Clashes are detected only

between visible elements.

-

Select Process also invisible representations to

extend the search for clashes to all hidden elements and the geometry of

impacting products and impacted representations.

This is useful for opening components with only Assembly Features definitions.

-

From the list, select an option to apply ordered rules.

- Skip Ordered Impact Rules

- Apply Ordered Impact Rules to All

- Apply Ordered Impact Rules for Fixing

Components.

-

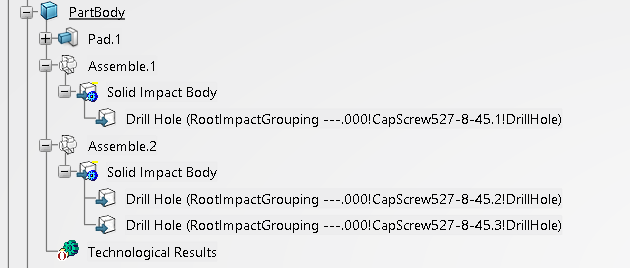

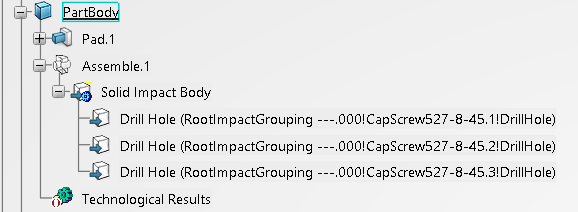

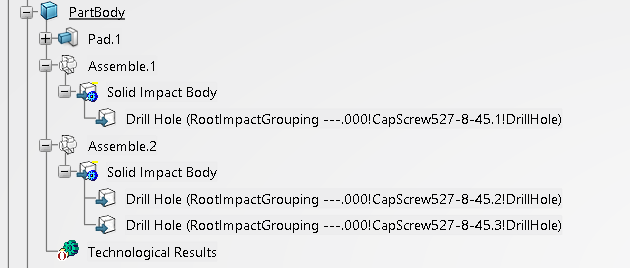

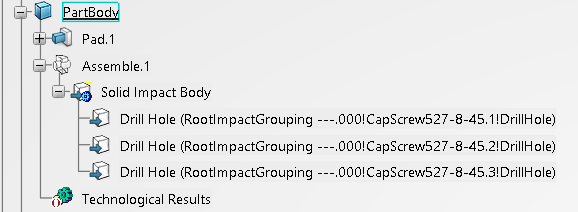

Select the Create new Assemble at each computation

check box to override the Preferences option Optimize grouping of

Solid Impacts into Bodies.

- When selected, creates an Assemble of Solid Impatcs at each impacts

creation, independantly of the status of Optimize

grouping of Solid Impacts into Bodies.

- When cleared, takes the status of Optimize grouping of

Solid Impacts into Bodies.

Note:

The status of Create new Assemble at each

computation is saved

Assembly Impacts are created for all the selected check boxes of Impact

Result. Modified Impacted Representations are visible in the 3D area.

For Mold Tooling Design Only

You can activate and take advantage of the captured events (Only for components

with Assembly Features), and delete impacts of created products.

-

Select an option from the list.

- No automatic preselection

- Automatic preselection of created

Products

- Automatic preselection of created or moved

Products

- The status of this option is taken into account and remembered when

you exit Components Impacts by OK or

Cancel.

- Any event associated with the new instantiation or replacement (or

move) of an impacting Component is memorized during the current session, until it is used the

next time you start Components Impacts.

- The captured events feed the automatic preselection of impacting

components the next time you start Components

Impacts.

- The option you have selected from the list is taken into account,

provided you have not previously selected impacting components. Any

occurrence of a component instance of the list that belongs to the

UI active product structure is added to the selection of impacting

products. Their impacts are computed.

-

Proceed as explained above.

- When you exit with OK, all the component instances for which an

occurrence was taken into account are removed from the list, the

events are seen as consumed.

- When you exit with Cancel, the list of events is kept.

- If you had entered Components Impacts with a

manual preselection, the automatic selection occurs the next time

you enter Components Impacts. However, if an

occurrence of a component of the list is manually selected and its

impact computed, the corresponding component instance is removed

from the list and no longer proposed in the preselection.

Notes:

- When an automatic preselection is selected, the events are

captured and stored in a list.

- The events are removed from this list when their impact is computed

- Either by Components Impacts

- Or by the context Impact command

- Or by the placement of a component with impact (The

newly instantiated component is first added to the list,

and immediately removed when applying the impact).

- If a component was automatically preselected, but manually

removed from Impact Result, the impact is not computed, the

event is not consumed and is kept for a future use.

- The list is persistent only within the session (not stored in

the database). It is completely erased when you exit the

session, or when you select No automatic

preselection.

- The list is partially erased when you go from

Automatic preselection of created or moved

Products to Automatic preselection of

created Products.

- Undo/redo is not supported in the list.

- If an event was consumed by an impact that is undone,

the event is not restored. The component is not proposed

again for automatic preselection.

- If an event was captured for a move operation, which is

undone, the event remains in the list, the component can

be proposed again for automatic preselection.

-

If required, select Delete Impacts of selected

products.

Notes:

- Existing impacts are deleted and new impacts computed in the

current context of the design. This is not an update of the

existing impact in the context where it was computed. This may

lead to alteration of the design intent.

- If the product is not up-to-date, the deletion fails. Cancel

Components Impacts, update the

product, restart Components Impacts.

When a component with impacts is moved, several cases may occur

depending on the other components it encounters in the Product context after

the move:

- The same Parts in clash lead to the same impacts.

Update updates all the impacts to their

correct geometry.

- Some impacted parts are no longer in clash.

Update makes the previous impacts

ineffective but they remain in the model.

- Some new parts are now in clash. Update does

not add them.

- The application of the ordered impact rules may keep the same parts

in clash, but the condition changes and the type of impact needs to

be changed, for example, a Cap screw is now going through the plate

after a design change. Update only updates

the previous impact type.

- With the application of the ordered impact rules for Assembly

features of type Pad and Pocket, the order of the objects in clash

(following the Component axis) may change the object to be impacted

by the Assembly feature.

All these reasons require that the existing impacts are deleted

before a new computation.

For every selected component (no matter how it was selected),

existing impacts are deleted. New impacts are computed and displayed for

every selected component. If you exit with Cancel, the deleted impacts are

restored.

|