About the Mold, Fill, and Pack Steps | |||||

|

| ||||

As you first begin to study an injection molding design, you might want to consider just the basic filling problem before adding the complexity of the Pack and Mold steps. The Simulate dialog allows you to selectively execute each of the steps, and provides a display of which results you already have available.

A typical investigation of an injection molding design involves running, modifying, and re-running the simulation steps several times to test your ideas for design and process improvements. You can run several steps at once, or you can run just one step, examine its results, and then run another step. The steps depend on results from each other as follows:

- Fill depends on results from Mold (if any).

- Pack depends on results from Fill, and Mold (if any).

- Mold does not use results from Fill or Pack, so it can be run at any time.

Because of these dependencies, there are a few rules concerning the order in which steps are executed:

- You must run Fill at least once before running Pack.

- If you re-run Fill, any existing Pack results become out-of-date.

- If you run or re-run Mold, any existing Fill and Pack results become out-of-date.

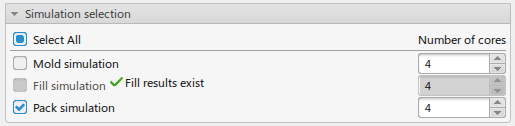

Check boxes in the

Simulation selection dialog box indicate which

steps to execute, provide messages indicating which results are already

available, and enable you to specify the number of CPUs to use during execution

of each step. The dialog box enables and disables step execution based on the

above dependencies and rules. As you modify your selections, the Cycle Times

diagram at the bottom of the Simulate dialog box changes, displaying segments

for the inactive steps in gray.