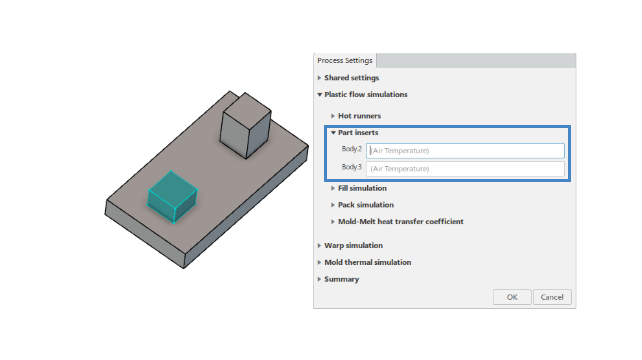

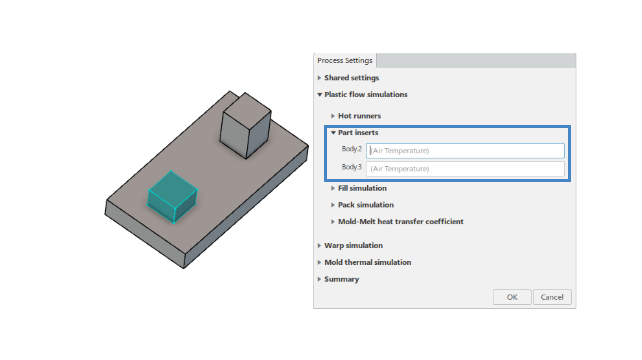

Ability to Specify the Temperatures of Part Inserts

You can now specify the temperatures of part inserts.

Previously, Plastic Injection assumed that any part inserts in your model were at ambient temperature. While this

approach is consistent with molding practices historically, an increasing portion of

the industry prefers to heat part inserts before placing them into the mold because

heating a part insert improves the bond between the part insert and the plastic

material.

Plastic Injection now lets you specify the temperature of each part insert at the start of the

plastic injection process. As you edit the initial temperature of a part insert in the

Process Settings dialog box, the app

highlights the part insert in teal, as shown in the image below.

Benefits: The ability to specify part insert temperatures allows you to simulate the

latest manufacturing trends.

For more information, see

About the General Settings

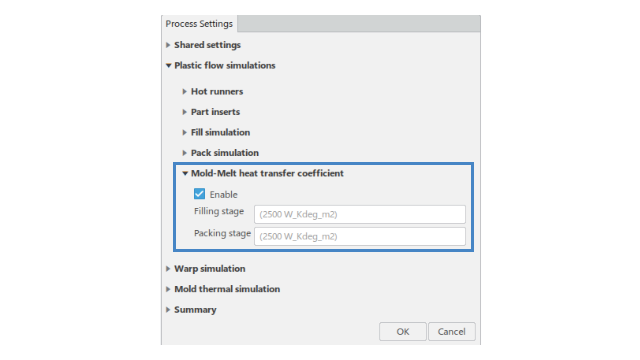

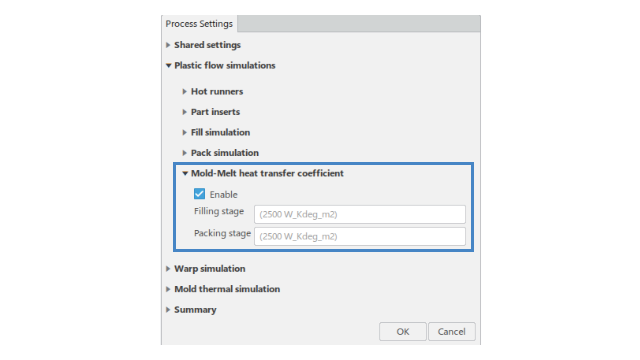

Mold-Melt Heat Transfer Coefficient

You can now specify the mold-melt heat transfer coefficient.

The heat transfer between the polymer material and the mold walls varies during the

different stages of the injection molding process. To represent the heat transfer

between the polymer material and the mold walls more accurately, you can now specify

heat transfer coefficient values for the Fill and Pack stages of the injection molding

process.

You can specify the heat transfer coefficients from the Process

Settings dialog box, as shown below.

Benefits: The mold-melt heat transfer coefficient allows you to simulate the plastic

injection process more accurately than before.

For more information, see

About the General Settings

Materials Database Updates

The plastic materials database now includes the latest material catalogs from

leading material suppliers.

The database update includes the addition, reclassification, and removal of

the materials listed below.Additional materials:

- 14 grades from EMS-GRIVORY

- 10 grades from SABIC Specialties

- Two grades from Trinseo

Reclassified materials:

- 19 grades from EMS-GRIVORY

- Five grades from Monsanto

- Five grades from VISTA CHEMICAL

- Three grades from SABIC Innovative Plastics

- Three grades from DAINIPPON INK

- Two grades from BASF

- Two grades from ARCO CHEM

- Two grades from Asahi Chemical

- Two grades from FPTC

- Two grades from Eastman Kodak

- One grade from Eastman Chemical

- One grade from DSM Engineering Plastics

- One grade from DuPont Engineering Polymers

- One grade from Aiou University

- One grade from Hoechst Celanese

- One grade from Hooker Chemical

Removed materials:

- Three grades from SABIC Specialties

- One grade from EMS-GRIVORY

- One grade from UNION CARBIDE

- One grade from an unnamed supplier

Benefits: An updated plastics materials database allows you to perform accurate and

lifelike plastics injection molding simulations using material grades you can purchase

later for manufacturing.

For more information, see

About Plastic Injection Materials