Scan Pattern–Mesh Intersection | ||||

|

| |||

ProductsAbaqus/Standard

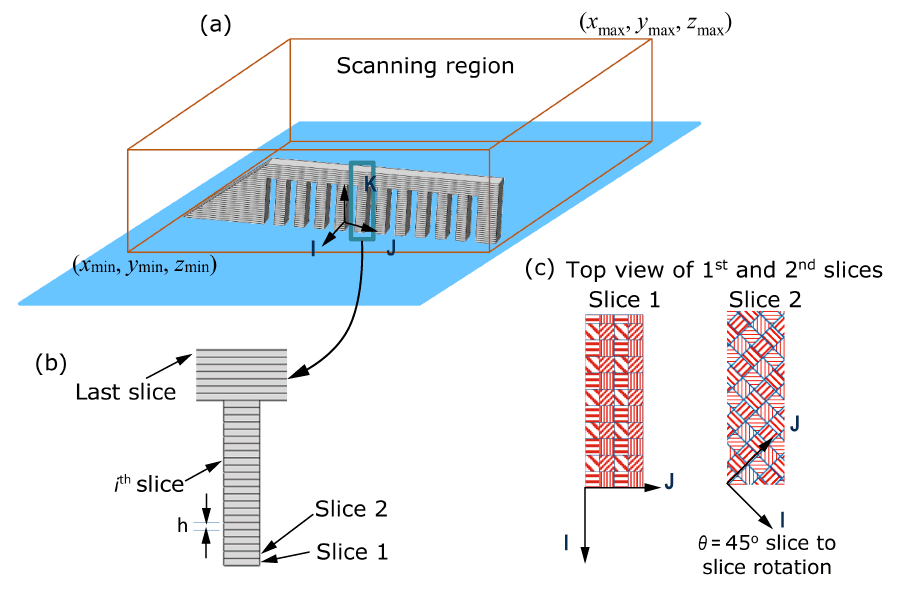

Some additive manufacturing processes are characterized by a tool

trajectory that follows a repetitive pattern in space; for example, powder bed

fusion with the laser beam following a predefined island scanning strategy. In

such cases, instead of describing individual trajectories of a toolpath, it is

more effective to define a scan pattern that represents the idealized motion of

a tool inside a part. The part being printed is divided into equally spaced

(uniform thickness, )

slices or cutting planes that are perpendicular to the build axis,

(see

Figure 1(a)

and

Figure 1(b)).

The build axis system

I–J–K is a

user-defined coordinate system that indicates the printing direction,

K.

The scan pattern consists of a rectangular unit cell (see

Figure 2).

The rectangular unit cell is repeated to cover the cutting plane. The

rectangular unit cell consists of a number of smaller rectangular patches. Each

patch can define a local angle, ,

between the direction of the scanning motion of the tool and the

I-axis. You can assign an eigenstrain tensor to each of

the pattern patches representing the inelastic deformation induced by the

process. You can define a scan pattern by defining extents of individual

patches (xmin,

ymin) and

(xmax, ymax).

All patches together must form a rectangular unit cell that must be situated

entirely in the first quadrant of the

I–J plane, and one corner of the cell

must be at (0, 0).

A scan pattern is active inside a scanning region. A scanning region is a build axis–oriented bounding box defined by its extent (xmin, ymin, zmin) and (xmax, ymax, zmax) (see Figure 1(a)). The height of a scanning region (zmax–zmin) must be an integral multiple of the thickness, h, of a slice. Multiple nonoverlapping scanning regions can be defined to cover the entire part. A different scan pattern can be active inside each scanning region. All scanning regions share the same build axis system. A layer-to-layer or slice-to-slice rotation angle, , can be defined. The scan pattern is rotated by on the slice for layer (see Figure 1(c)).

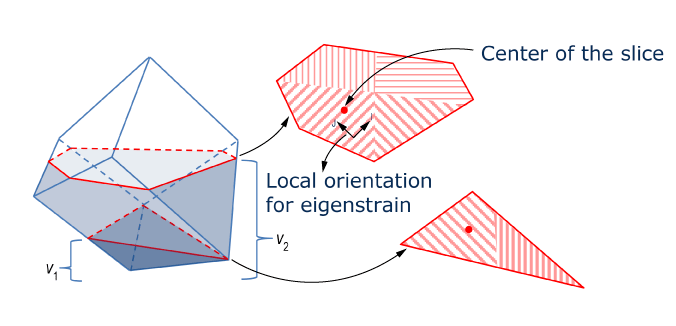

For a given element, the toolpath-mesh intersection module computes the

number of slices, m, inside the element in a given

increment (see

Figure 3).

It finds which pattern patch contains the center of each slice in that element

and the local orientation of that patch considering the layer-to-layer

rotation, ,

and the local rotation, ,

of the scanning direction in that patch. The module also computes the partial

volumes, ,

of the element below each slice.