Problem description

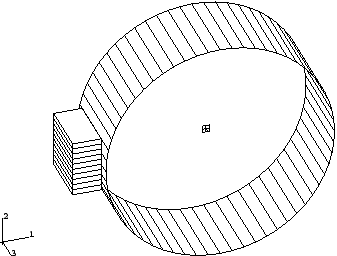

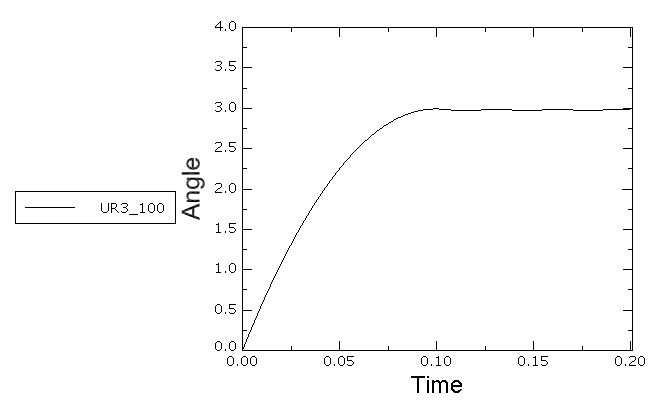

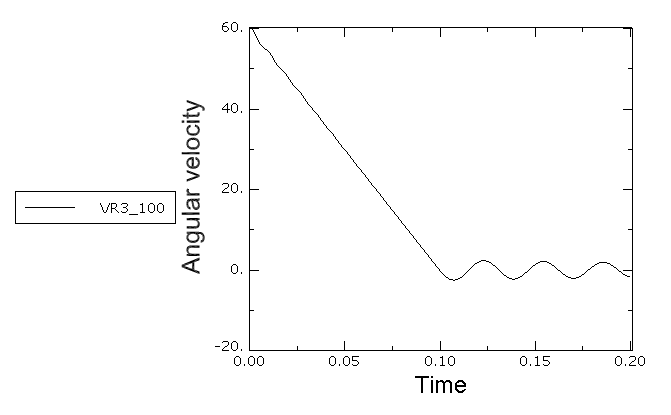

The problem consists of a rigid drum, initially rotating at 60 rad/s about a fixed axis, that is brought to rest by frictional contact with a pad of hyperelastic material. The rigid drum has a radius R of 200 mm and width of 150 mm, total mass of 5 kg, and rotary inertia of 0.175 kg m2 about its free axis of rotation. The deformable pad is a 100 × 100 × 50 mm block of hyperelastic material, having a polynomial strain energy function of order 1 with constants 0.552 MPa, 0.138 MPa and 0.145 × 10−6 MPa. A constant pressure 0.350 MPa is applied to the back of the pad to force it against the rigid drum. A Coulomb friction coefficient of 15% is assumed to exist between the pad and the drum. Both two-dimensional and three-dimensional idealizations of the problem are used for verification.

For two dimensions the rigid drum is modeled in two different ways:

-

The rigid drum is modeled as an analytical rigid surface using a planar analytical surface in conjunction with a rigid body constraint.

-

The rigid drum is discretized using 72 rigid elements of type R2D2.

The analytical rigid surface can yield a more accurate representation of two-dimensional curved punch geometries and result in computational savings. Contact pressure can always be viewed on the specimen surface, and the punch reaction force is available at the rigid body reference node. Results for the element facet representations are presented here.

For three dimensions the rigid drum is modeled in five different ways, as described below:

-

The rigid drum is modeled as an analytical rigid surface using a cylindrical or revolution analytical surface in conjunction with a rigid body constraint. This model is analyzed using contact pairs as well as general contact.

-

The rigid drum is discretized using 72 rigid elements of type R3D4.

-

Membrane elements of type M3D4R are used to model the drum, and they are included in the rigid body by referring to them in the rigid body constraint. A zero material density is specified for the membrane elements; and to make this model comparable to Case 1, a zero-thickness surface is used when defining the outer surface of the drum.

-

Shell elements of type S4R are used to model the drum, and they are included in the rigid body by referring to them in the rigid body constraint. A zero material density is specified for the shell elements; and to make this model comparable to Case 1, a zero-thickness surface is used when defining the outer surface of the drum.

-

Solid elements of type C3D4 are used to model the drum, and they are included in the rigid body by referring to them in the rigid body constraint. A zero material density is specified for the C3D4 elements.

The reference node of the rigid drum is located on the axis of rotation. Since we have chosen to place the reference node at the center of mass for the rigid body, a single MASS element and a ROTARYI element at the reference node are used to define the complete inertial properties for the rigid body.

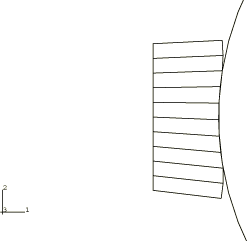

The deformable pad is discretized into 10 equally spaced elements (CPE4R in two dimensions and C3D8R in three dimensions). A rigid plate has been added to the back face of the deformable pad, using R2D2 elements in two dimensions and R3D4 elements in three dimensions, to constrain these nodes to remain in a plane. This rigid plate is a second rigid body, firmly attached to the pad, and with the motion of its reference node constrained in all but the local x-direction. Hence, the pad is free to move toward the drum or away from it, but it can neither translate nor rotate in any other direction.