The results for each test are presented in two plots: one showing the

stress/strain response and the other showing the variation of the permanent

volumetric strain with the applied stress. For each plot two sets of data are

presented: one corresponds to Coffin's experimental data, and the other

corresponds to the

Abaqus

simulation.

Figure 2,

Figure 3,

and

Figure 4

compare the prediction of the model with the experimental test data in uniaxial

tension and uniaxial compression, respectively. All the figures show good

agreement between the test data and experimental results. This behavior is to

be expected since the model is calibrated using uniaxial test data.

Figure 5

shows that small (compared to the strain in

Figure 4)

permanent volume changes were observed in the uniaxial compression experiment.

The model in

Abaqus

predicts zero permanent volume change under uniaxial compression and higher

confining stresses.

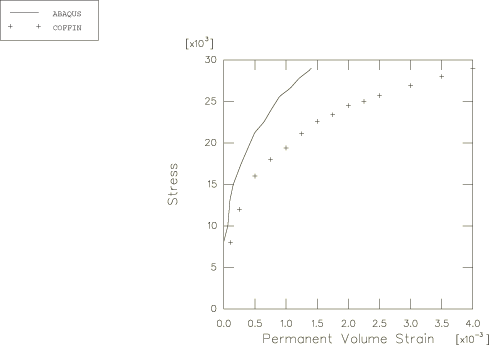

The results for equibiaxial tension are presented in

Figure 6

and

Figure 7.

At high stress values

Abaqus

predicts a stiffer response. The error in the stress/strain response is about

20% at 70% of the fracture stress and higher for higher stress values. The

error in the stress/strain response at high stresses is probably because the

Rankine yield criterion is only an approximation to the real material behavior

under equibiaxial loading conditions.

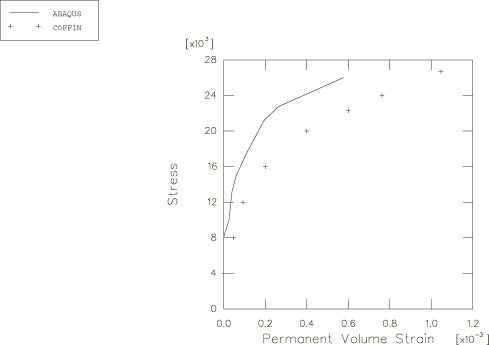

The results for pure shear are shown in

Figure 8

and

Figure 9.

Again,

Abaqus

predicts a stiffer response at high stress values. The error in the

stress/strain response is about 20% at 70% of the fracture stress and higher

for higher stress values. The stress/strain response of the simulation

indicates a change in the rate of hardening at very high stresses. This

behavior is due to a change in the yielding mechanism from Rankine to Mises.

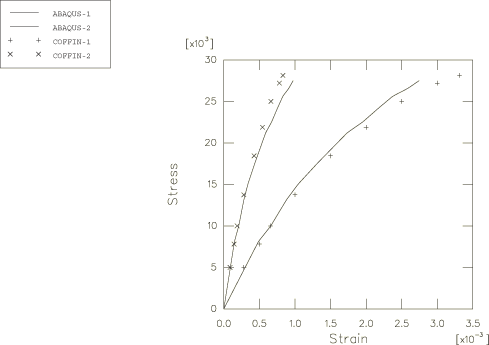

Figure 10

and

Figure 11

show the results for unequal biaxial tension, where the applied loading in one

direction is twice of that in the other. In both the figures the strains are

plotted against the maximum principal stress. In

Figure 10

the curves labeled “Abaqus–1”

and “COFFIN-1” correspond to the maximum

principal stress versus the maximum principal strain, and the curves labeled

“Abaqus–2”

and “COFFIN-2” correspond to the maximum

principal stress versus the intermediate principal strain. The stress/strain

response predicted by

Abaqus

is in good agreement with the experimental results. The difference between the

numerical and experimental results for the permanent volume strain under high

stresses suggests that the minimum principal strain has not been captured as

accurately as the other principal strains in the numerical simulation. The

reason for the better agreement in the stress/strain results for unequal

biaxial tension as compared to those for equibiaxial tension and shear may be

that the loading path is, in relative terms, closer to the uniaxial tension

loading path and that the model is calibrated with uniaxial tension results.

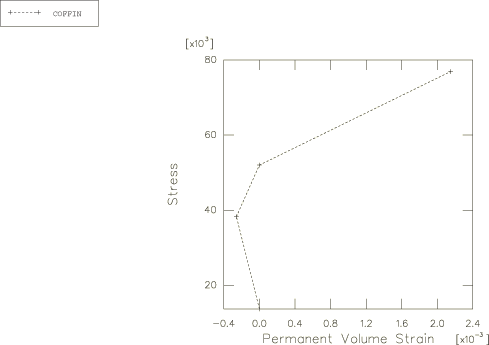

Finally, the case of biaxial tension/compression is shown in

Figure 12

and

Figure 13.

The loading for this test consists of tension in one direction and compression,

with twice the magnitude of the tensile load, in the other direction. The

stress/strain response as predicted by

Abaqus

agrees well with the experimental results. The loading path for this case is

close to the loading path for uniaxial compression, and the model is calibrated

with uniaxial compression results. In

Figure 13

the experimental results indicate a very high value for the maximum permanent

volume change. Given that the loading is predominantly compressive, such a high

value of the permanent volume change is somewhat surprising. It is possible

that such a permanent volume change may be related to effects such as

microbuckling of the graphite flakes; the

Abaqus

model does not capture this behavior.