Problem description

Stress and strain data are entered using uniaxial test data, biaxial test data, planar test data, and volumetric test data for the hyperelastic material model. A least squares method is used to fit the experimental data. For the polynomial and Ogden forms the order of the series (N) is specified for the hyperelastic material model. The following cases are analyzed:

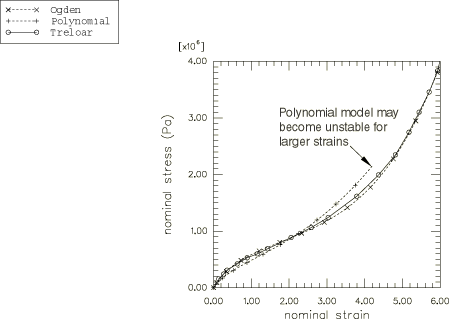

Polynomial form with N=2 (5 deviatoric terms).

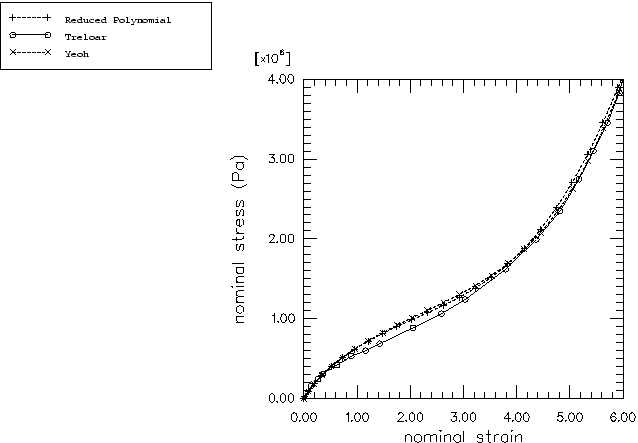

Reduced polynomial form with N=4 (4 deviatoric terms).

Yeoh form, which is equivalent to the reduced polynomial form with N=3.

Ogden form with N=3 (3 deviatoric terms).

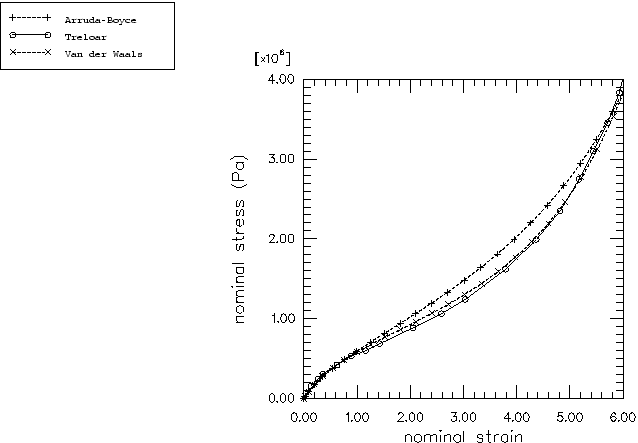

Arruda-Boyce form.

Van der Waals form.

The stress values are given in pascals. The density of the material is 1000 kg/m3. A state of simple uniaxial tension is induced in the cube up to a strain of 600%. The stretching velocity is ramped up from zero to 6.0 m/s within 2.0 seconds. The coefficients fitted by using the polynomial strain energy potential with N=2 may lead to unstable material behavior when the nominal strain in a uniaxial tensile test reaches approximately 440%. (Unstable regimes for hyperelastic materials are discussed in Hyperelastic Behavior of Rubberlike Materials.) Therefore, for that particular analysis the final deformation was set to be 400% by ramping the velocity from zero to 4.2 m/s within 2.0 seconds.