An “exact” solution is developed by first defining the total strain rates,

and ,

as functions of the stress rates

and .

The resulting rate equations are then integrated numerically with high accuracy

to give a reference solution.

Ziegler's kinematic hardening gives, under isothermal conditions,

where

where

is the yield stress and

where C is the slope of the stress versus plastic

strain curve under uniaxial loading conditions.

Under plane stress conditions ()

and with ,

and

where

and

Hence,

and

where ,

The stress rate-strain rate relation is, therefore,

where ,

,

and

Inverting this relationship gives the total strain rates as

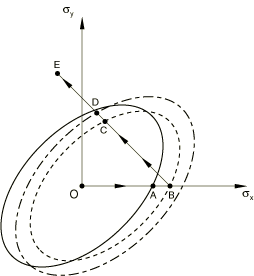

The center of the yield surface translates according to Ziegler's kinematic

hardening rule, so that

where

Hence,

and the translation rate at the center of the yield surface is given in

components by

Given the values of the variables ,

,

,

,

and ,

at the beginning of the increment, together with the prescribed stress

increments

and ,

the total strain rate equation and the translation rate equation for the center

of the yield surface provide the values of ,

,

,

and .

A small program for calculating the required variables is given in ornlbiaxialload_exact.f. The main program

provides prescribed stress increments

and

equal to those used in the finite element analysis. Each of these

increments is then split into 1000 subincrements, and the total strain rate equation

and the translation rate equation for the center of the yield surface are integrated

over each subincrement to provide virtually exact values of

,

,

, and

, corresponding to the prescribed values of

and

used in the analysis. In each of the subincrements, a test is made

to determine if

When this test is satisfied, the yield surface is expanded from

the virgin properties to the 10th cycle properties so that

is increased from its virgin value of 207 MPa (30000

lb/in2) to its 10th cycle value of 234 MPa (34000 lb/in2).

This value of

is used in each subincrement following the initial satisfaction of

the test

, according to the ORNL plasticity

algorithm.