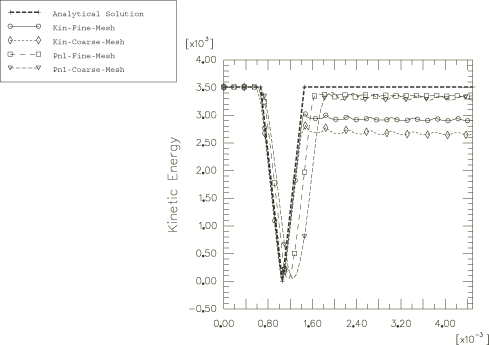

Verification for this problem is provided by comparing the values of

significant problem variables with the analytical solution. The numerical

solutions are based on the default time incrementation except where noted.

Plots of kinetic energy are shown in

Figure 4.

Four stages of the solution (pre-impact, truss compression, truss re-expansion,

and postimpact) are apparent in this plot. When penalty contact is used, the

latter stages are delayed and changes in the slope at the transitions between

these stages are smoothed. The onset of truss compression is advanced in time

by one increment with kinematic contact. In each of the numerical solutions the

kinetic energy is not entirely recovered upon rebound because of the numerical

dissipation of energy and finite discretization. For the penalty contact

solutions the dissipation of energy is primarily caused by small amounts of

bulk viscosity (included by default in the

Abaqus/Explicit

element formulations) and viscous contact damping (included by default for

penalty contact). For the kinematic contact solutions both the bulk viscosity

and the contact algorithm itself contribute significantly to the loss of

energy. The kinematic contact algorithm dissipates the kinetic energy of the

contact node upon impact, whereas the penalty contact algorithm converts the

kinetic energy of the contact node into energy stored in the stretched penalty

spring. These energy transfer considerations will be discussed further in the

following paragraphs.

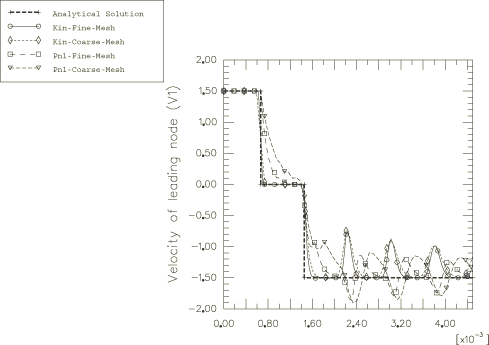

Velocity histories of the leading truss node (contact node) are plotted in

Figure 5.

The kinematic contact solutions for velocity closely match the analytical

solution during pre-impact and during impact. The impact stage is less distinct

in the velocity plots for penalty contact because some penetration occurs. All

numerical solutions for the postimpact velocity show some oscillations that are

not part of the analytical solution. These oscillations are associated with the

energy dissipation and finite discretization. In the kinematic contact

solutions a stress wave continues to pass through the truss during the

postimpact phase, which periodically reduces the magnitude of the nodal

velocity. This wave becomes narrower as the mesh is refined. With penalty

contact a postimpact stress wave persists, which causes the postimpact nodal

velocity to oscillate about approximately −1.5 m/s, where the negative velocity

indicates movement in the negative x-direction. In all

numerical solutions these velocity oscillations become more diffuse over time

as a result of the bulk viscosity damping.

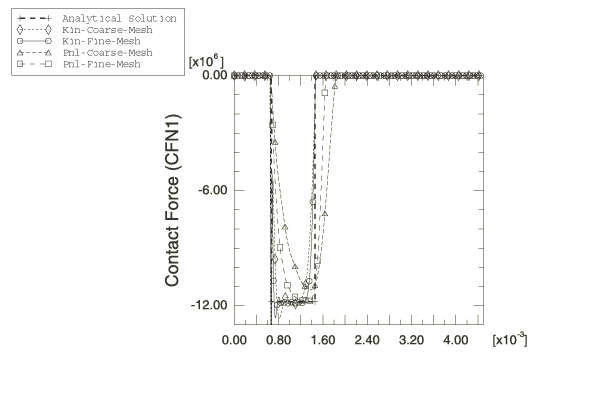

Contact force history solutions are plotted in

Figure 6.

For the kinematic contact tests

Abaqus/Explicit

gives very good estimates of the peak contact force and captures the steps in

the contact force history quite well. However, it will be shown later that the

contact force history with kinematic contact depends on the size of the time

increment used in the analysis. The penalty contact force solutions produce

reasonable estimates of the peak contact force, but because of the inherent

numerical softening of the penalty method, extreme mesh refinement is needed to

observe sudden jumps in contact force.

Figure 7

contains plots of external work. The external work remains zero in the

analytical solution. Some external work associated with contact forces, which

are treated as external forces in

Abaqus/Explicit,

can be observed in the numerical solutions. With penalty contact the external

work accounts for the energy stored in the penalty springs during contact

penetration and the energy dissipated by viscous contact damping. After the

rebound the external work returns to a constant negative value as the penalty

spring energy is recovered; the negative value corresponds to the amount of

dissipation due to viscous contact damping. With kinematic contact a contact

force first occurs in the increment just prior to the actual impact when a gap

is still present; thus, penetration does not occur in the next increment.

Therefore, the kinematic contact force does some work when contact is first

established. This work corresponds to the kinetic energy of the contact node,

and this energy is dissipated by the contact algorithm and is not recovered

upon the rebound.

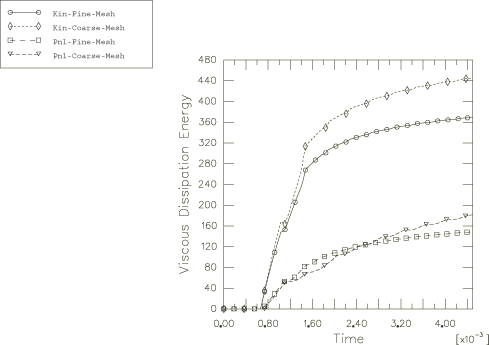

The energy dissipation caused by the bulk viscosity is plotted in

Figure 8.

This dissipation is greater with kinematic contact than with penalty contact

because impacts in the kinematic contact formulation are not softened. Greater

shock to the elements and increased element damping occur. Energy continues to

dissipate after the rebound as a result of damping of stress waves that persist

in the truss after the rebound.

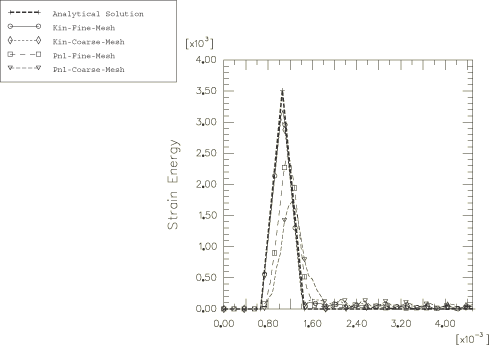

Plots of strain energy are shown in

Figure 9.

The energy stored in penalty springs is not included in the strain energy

reported by

Abaqus/Explicit,

because the contact forces are treated as external forces. Instead, the energy

stored in penalty springs appears as negative external work, as mentioned

previously. Some strain energy remains after the rebound in the numerical

solutions, which is related to stress waves that remain in the truss.

An undesirable characteristic of the kinematic contact algorithm is that the

initial impact force predicted for a given mesh over the contact region depends

on the size of the time increment. The contact force results shown in

Figure 10

are based on analyses in which the time increment was scaled by 0.25. This

scaling simulates the presence of a small element in the model that would

control the time increment size. The kinematic contact algorithm will

overestimate impact forces if the time increment is significantly lower than

the stable time increments of elements near the contact region. Reducing the

time increment causes the contact force to increase, because the approach speed

of the leading node must be resolved over a shorter time interval to avoid

penetration upon impact.

Figure 10

also shows that the time increment size has negligible influence on the contact

force solution if the penalty contact formulation is used. Other solution

variables discussed in this example have minimal dependence on the size of the

time increment for both types of contact constraint methods.

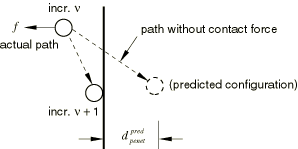

To better understand these results, consider a single secondary node impacting a fixed rigid

wall. Figure 11 and Figure 12 show such a contact secondary node as a circle in increment

. Friction will not be considered.

In the kinematic contact formulation

Abaqus/Explicit

calculates a predicted penetration

(see

Figure 11).

This predicted penetration is equal to the movement of the node if no contact

condition is enforced.

Abaqus/Explicit

then calculates the contact force, ,

in the normal direction according to

and applies this force in the current increment. The contact force is

applied before the contact is actually established. In the next increment,

+1,

the node contacts the surface of the opposing body without penetration (see

Figure 11)

and the loss of kinetic energy occurs. Although not shown in

Figure 11,

a contact force will also occur in increment +1

in the case of kinematic contact to eliminate the remainder of the velocity

component normal to the surface.

Figure 12

shows the schematic for the penalty contact formulation. The contact force is

first applied in increment +1,

and some penetration of the node into the opposing surface occurs. The contact

force

is calculated according to

where k is the penalty stiffness calculated by

Abaqus/Explicit,

c is the viscous damping coefficient calculated from the

default contact damping setting, and

is the penetration velocity. The penalty stiffness term can be envisioned

physically as a spring attached between the penetrating node and the surface

being penetrated. The energy is stored in this spring and is released as the

node penetration reverses and decreases to zero (see

Figure 7).

The small amount of kinetic energy lost (see

Figure 4)

is the result of viscous effects of the elements, viscous contact damping, and

strain energy remaining in the truss after separation (see

Figure 9).

As the mesh is refined, both formulations tend toward the analytical solution.