Defining Derived Components for Connector Elements

The definition of coupled behavior in connector elements beyond simple linear elasticity or damping often requires the definition of a resultant force involving several intrinsic (1 through 6) components or the definition of a “direction” not aligned with any of the intrinsic components. These user-defined resultants or directions are called derived components. The forces and motions associated with these derived components are functions of the forces and motions in the intrinsic relative components of motion in the connector element.

Consider the case of a SLOT connector for which frictional effects (see Connector Friction Behavior) are defined in the only available component of relative motion (the 1-direction). The two constraints enforced by this connection type will produce two reaction forces ( and ), as shown in Figure 1. Both forces generate friction in the 1-direction in a coupled fashion.

A reasonable estimate for the resulting contact force is

where is the collection of connector forces and moments in the intrinsic components. The function can be specified as a derived component.

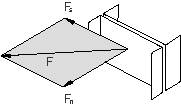

Resultant forces that can be defined as derived components may take more complicated forms. Consider a BUSHING connection type for which a tensile (Mode I) damage mechanism with failure is to be specified in the 1-direction. You may wish to include the effects of the axial force and of the resultant of the “flexural” moments and in defining an overall resultant force in the axial direction upon which damage initiation (and failure) can be triggered, as shown in Figure 2.

One choice would be to define the resultant axial force as

where is a geometric factor relating translations to rotations with units of one over length. The function can be specified as a derived component.

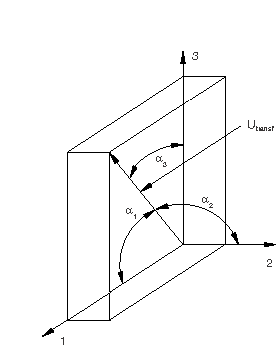

A derived component can also be interpreted as a user-specified direction that is not aligned with the connector component directions. For example, if the motion-based damage with failure criterion in a CARTESIAN connection with elastic behavior does not align with the intrinsic component directions, the damage criterion can be defined in terms of a derived component representing a different direction, as shown in Figure 3.

One possible choice for the direction could be

where is the collection of connector relative motions in the components and , , and can be interpreted as direction cosines (, , ). The function can be specified as a derived component.

Functional Form of the Derived Component

The functional form of a derived component in Abaqus is quite general; you specify its exact form. The derived component is specified as a sum of terms

where is a generic name for the connector intrinsic component values (such as forces, , or motions, ), is the term in the sum, and is the number of terms. The appropriate component values for are selected depending on the context in which the derived component is used. is also a summation of several contributions and can take one of the following three forms:

-

a norm (-type)

-

a direct sum (-type)

-

a Macauley sum (-type)

where is the term's sign (plus or minus), are scaling factors, is the component of , and is the Macauley bracket ( ). In general, the units of the scaling factors depend on the context. In most cases they are either dimensionless, have units of length, or have units of one over length. The scaling factors should be chosen such that all the terms in the resulting derived component have the same units, and these units must be consistent with the use of the derived component later on in a connector potential or connector contact force.

Defining a Derived Component with Only One Term (NT = 1)

Connector derived components are identified by the names given to them. If one term () is sufficient to define the derived component g, specify only one connector derived component definition.

Input File Usage

CONNECTOR DERIVED COMPONENT, NAME=derived_component_name

Defining a Derived Component Containing Multiple Terms (NT > 1)

If several terms (, , etc.) are needed in the overall definition of the derived component g, you must define the individual terms.

Input File Usage

You must specify connector derived component definitions with the same name to define the individual terms. All definitions with the same name will be summed together to produce the desired derived component g. See the spot weld example below for an illustration.

CONNECTOR DERIVED COMPONENT, NAME=derived_component_name CONNECTOR DERIVED COMPONENT, NAME=derived_component_name ...

Specifying a Term in the Derived Component as a Norm

By default, a derived component term is computed as the square root of the sum of the squares of each intrinsic component contribution. If the term has only one contribution (), the norm has the same meaning as the absolute value.

Input File Usage

CONNECTOR DERIVED COMPONENT, NAME=derived_component_name, OPERATOR=NORM (default)

For example, the following input can be used to define the component discussed above:

CONNECTOR DERIVED COMPONENT, NAME=axial 1 1.0, ** CONNECTOR DERIVED COMPONENT, NAME=axial 5, 6 , **

The axial derived component is

.

Specifying a Term in the Derived Component as a Direct Sum

Alternatively, you can choose to compute a derived component term as the direct sum of the intrinsic component contributions.

Input File Usage

CONNECTOR DERIVED COMPONENT, NAME=derived_component_name, OPERATOR=SUM

For example, the following input can be used to define the component discussed above:

CONNECTOR DERIVED COMPONENT, NAME=transf, OPERATOR=SUM 1, 2, 3 , , **

The transf derived component is

.

Specifying a Term in the Derived Component as a Macauley Sum

Alternatively, you can choose to compute a derived component term as the Macauley sum of the intrinsic component contributions.

Input File Usage

CONNECTOR DERIVED COMPONENT, NAME=derived_component_name, OPERATOR=MACAULEY SUM

For example, the following input can be used to define the first term of the normal component of the force () in the spotweld example discussed below:

CONNECTOR DERIVED COMPONENT, NAME=normal, OPERATOR=MACAULEY SUM 3 1.0 **

Specifying the Sign of a Term

You can specify whether the sign of a derived component term should be positive or negative.

Input File Usage

Use one of the following options:

CONNECTOR DERIVED COMPONENT, NAME=derived_component_name, SIGN=POSITIVE (default) CONNECTOR DERIVED COMPONENT, NAME=derived_component_name, SIGN=NEGATIVE

Defining the Derived Component Contributions to Depend on Local Directions

The scaling factors used in the definition of the derived component can depend on the relative positions or constitutive displacements/rotations in several component directions, as described in Defining Nonlinear Connector Behavior Properties to Depend on Relative Positions or Constitutive Displacements/Rotations. See the first example in Connector Friction Behavior for an illustration.

Input File Usage

Use the following option to define a connector derived component that depends on components of relative position:

CONNECTOR DERIVED COMPONENT, INDEPENDENT COMPONENTS=POSITION

Use the following option to define a connector derived component that depends on components of constitutive displacements or rotations:

CONNECTOR DERIVED COMPONENT, INDEPENDENT COMPONENTS=CONSTITUTIVE MOTION

Requirements for Constructing a Derived Component Used in Plasticity or Friction Definitions

When a derived component is used to construct the yield function for a plasticity or friction definition, the following simple requirements must be satisfied:

-

All terms of a derived component must be of a compatible type (see Functional Form of the Derived Component); norm-type terms (-type) cannot be mixed with direct sum-type terms (-type) in the same derived component definition but can be mixed with Macauley sum-type terms (-type).

-

If all terms are norm-type terms, the sign of each term must be positive (the default).

If is greater than 1, the associated functions (potentials) in which the derived component is used may become non-smooth. More precisely, the normal to the hyper-surface defined by the potential may experience sudden changes in direction at certain locations. In these cases, Abaqus will automatically smooth-out the defined functions by slightly changing the derived component functional definition. These changes should be transparent to the user as the results of the analysis will change only by a small margin.

Example: Spot Weld

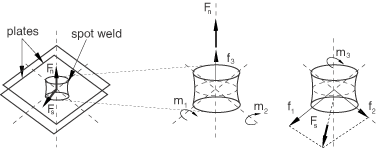

The spot weld shown in Figure 4 is subjected to loading in the F-direction.

The connector chosen to model the spot weld has six available components of relative motion: three translations (components 1–3) and three rotations (components 4–6). You have chosen this connection type because you are modeling a general deformation state. However, you would like to define inelastic behavior in the connection in terms of a normal and a shear force, as shown in Figure 5, since experimental data are available in this format.

Therefore, you want to derive the normal and shear components of the force, for example, as follows:

In these equations and have units of length; their interpretation is relatively straightforward if you consider the spot weld as a short beam with the axis along the spot weld axis (3-direction). If the average cross-section area of the spot weld is A and the beam's second moment of inertia about one of the in-plane axes is (or ), can be interpreted as the square root of the ratio (or ). Furthermore, if the cross-section is considered to be circular, becomes equal to a fraction of the spot weld radius. In all cases can be taken to be .

The reasoning above for the interpretation of the calibration constants in the equations is only a suggestion. In general, any combination of constants that would lead to good comparisons with other results (experimental, analytical, etc.) is equally valuable.

To define , you would specify the following two connector derived component definitions, each with the same name:

PARAMETER =30.68 A=19.63 =sqrt() = CONNECTOR DERIVED COMPONENT, NAME=normal, OPERATOR=MACAULEY SUM 3 1.0 CONNECTOR DERIVED COMPONENT, NAME=normal 4, 5 ,

The symbols denote that is specified using a parameter definition. The normal force derived component is defined as the sum of two terms, . The first connector derived component defines the first term , while the second defines the second term .

Similarly, to define ,

you would specify the following two connector derived component definitions for

the component shear:

CONNECTOR DERIVED COMPONENT, NAME=shear 6 CONNECTOR DERIVED COMPONENT, NAME=shear 1, 2 1.0, 1.0