Problem description

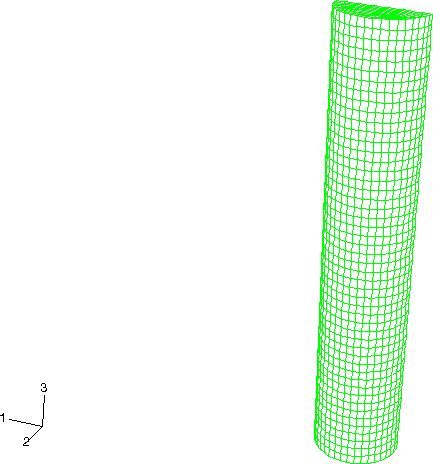

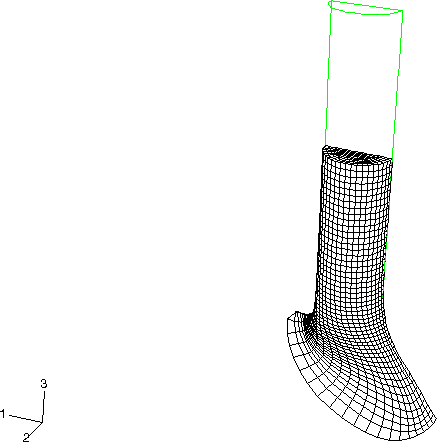

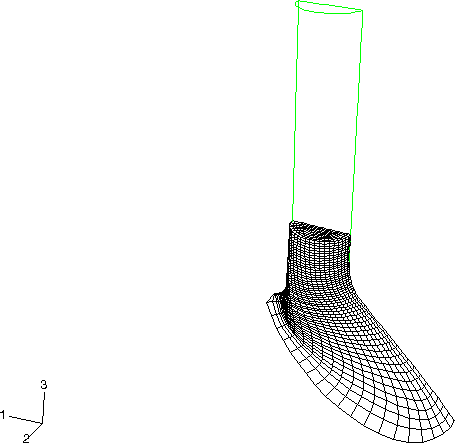

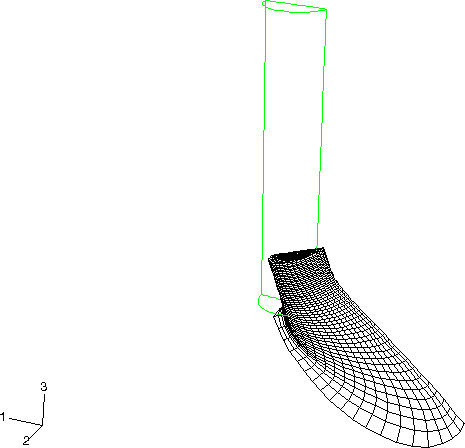

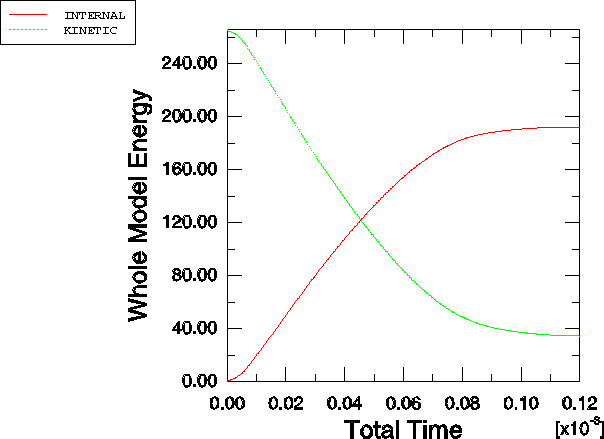

The model geometry is depicted in Figure 1. A cylindrical rod, measuring 32.4 × 3.2 mm, impacts a rigid wall with an initial velocity of =340 m/sec. The wall is perpendicular to the x–z plane and makes an angle of 30° with the x–y plane. The half-symmetric finite element model is shown in Figure 2. Symmetry boundary conditions are applied at the y=0 plane. The rod is meshed with CAX4R elements, and the wall is modeled as an analytical rigid surface using a three-dimensional cylindrical surface in conjunction with a rigid body constraint. Coulomb friction is assumed between the rod and the wall, with a friction coefficient of 0.2. The analysis is performed for a period of 120 microseconds.

The rod is modeled as a Johnson-Cook, elastic-plastic material with a Young's modulus of 124 GPa, a Poisson's ratio of 0.34, and a density of 8960 kg/m3. The Johnson-Cook model is appropriate for modeling high-rate impacts involving metals. The Johnson-Cook material parameters are taken from Johnson and Cook (1985) in which the following constants are used: 90 MPa, 0.31, 1.09, 0.025, and 1 s−1. Furthermore, the melting temperature is 1058°C, and the transition temperature is 25°C. Adiabatic conditions are assumed with a heat fraction of 50%. The specific heat of the material is 383 J/Kg°C, and the thermal expansion coefficient is 0.00005°C−1.