Problem description

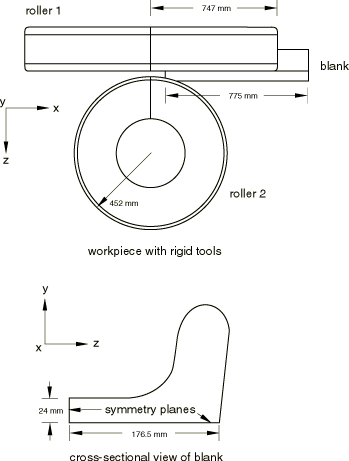

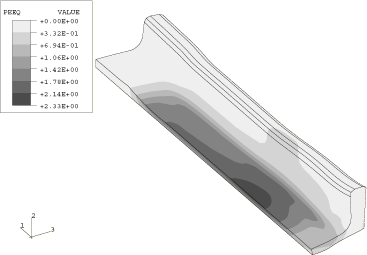

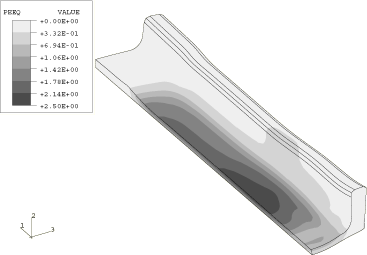

This analysis shows a stage in the rolling of a symmetric I-section. Because of the cross-sectional shape of the I-section, two planes of symmetry exist and only a quarter of the section needs to be modeled. The quarter-symmetry model, shown in Figure 1, consists of two rigid rollers and a blank. Roller 1 has a radius of 747 mm, and roller 2 has a radius of 452 mm. The blank has a length of 850 mm, a web half-width of 176.7 mm, a web half-thickness of 24 mm, and a variable flange thickness.

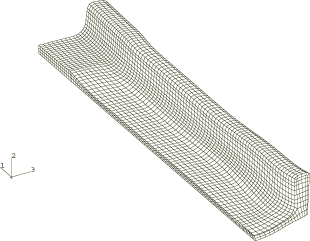

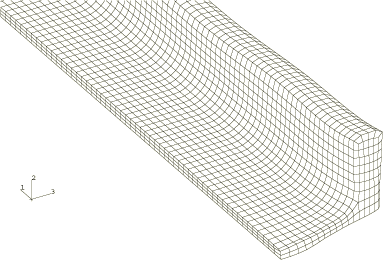

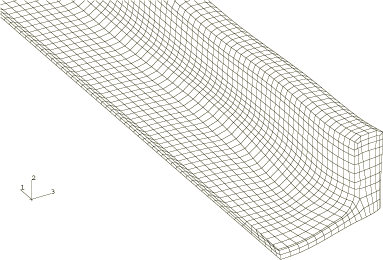

The finite element model is shown in Figure 2. The blank is meshed with C3D8R elements. Symmetry boundary conditions are applied on the y and z symmetry planes of the blank. The rollers are modeled as three-dimensional revolved analytical rigid surfaces. Roller 1 has all degrees of freedom constrained except rotation about the z-axis, where a constant angular velocity of 5 rad/sec is specified. Roller 2 has all degrees of freedom constrained except rotation about the y-axis. An initial velocity of 4187.0 mm/sec in the negative x-direction is applied to the blank to initiate contact between the blank and the rollers. This velocity corresponds to the velocity of the rollers at the point of initial contact.

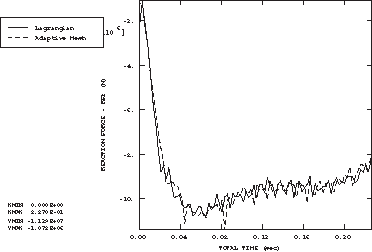

Variable mass scaling is used to scale the masses of all the blank elements so that a desired minimum stable time increment is achieved initially and the stable time increment does not fall below this minimum throughout the analysis. The loading rates and mass scaling definitions are such that a quasi-static solution is generated.

The blank is steel and is modeled as a von Mises elastic-plastic material with a Young's modulus of 212 GPa, an initial yield stress of 80 MPa, and a constant hardening slope of 258 MPa. Poisson's ratio is 0.281; the density is 7833 kg/m3. Coulomb friction with a friction coefficient of 0.3 is assumed between the rollers and the blank.