Geometry and model

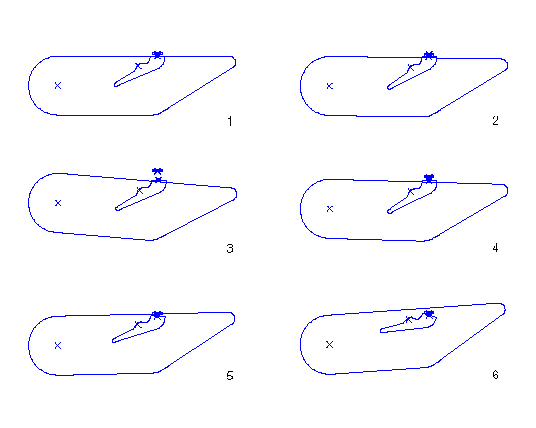

A snubber is used to cushion the closing of a cowling on an aircraft. The cowling opens and closes by applying a torque about the Z-axis at a fixed point (the origin, Q, in Figure 1). The snubber-arm assembly is attached to the cowling at point C. The snubber arm is constrained at point A by a spring and is allowed to rotate relative to the cowling about point C. The other end of the spring is attached to the cowling at point E. A shoe is attached to the snubber arm at point B and contacts with a block as the cover closes, as shown in detail in Figure 2. The shoe is allowed to pivot about point B. The spring retains the snubber arm against a stop on the cowling with an initial force of 50 lbs when the cover is open. The shoe contacts the block as the cover closes.

A small rotational spring (10 lb/rad) keeps the shoe from rotating relative to the snubber arm while the shoe is not in contact with the block. The block is fixed to the ground. As the shoe comes into contact, the two surfaces slide relative to each other. The coefficient of friction between the block and the shoe is 0.5.

The closing speed of the cowling is slow enough so that inertia effects can be neglected. Figure 1 shows the position of the mechanism when the shoe and the block make initial contact. The cowling rotates five more degrees about point Q after the block and the shoe make initial contact.