Elements tested

- C3D8R

- C3D10

- C3D10M

- C3D20

- C3D4

- C3D8T

- C3D20RT

- CAX3H

- CAX4

- CGAX4HT

- CGAX8RT

- CPE3

- CPE4

- CPE6

- CPE6H

- CPE8

- CPE8R

- CPEG3HT

- CPEG4HT

- C3D8P

- C3D20RP

- CAX4P

- CAX8RP

- CPS3

- CPS4

- CPS4T

- DC2D4

ProductsAbaqus/Standard Elements tested

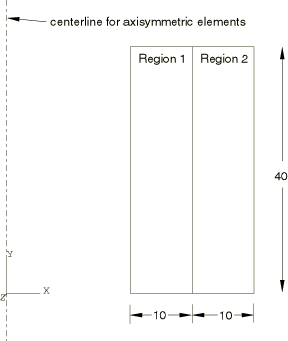

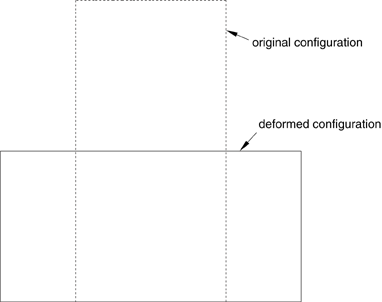

Features testedSolution variables transfer capabilities Problem descriptionThe verification tests in this section consist of pairs of models. Within each pair the first, or ancestor, model undergoes a simple deformation to a deformed configuration. The second, or descendent, model represents the deformed configuration of the ancestor with a different mesh and possibly with different element types. The solution from the ancestor model is transferred to the descendent model, and the resulting state of this model is verified to be consistent with the ancestor in its deformed configuration. Model:The ancestor model has a simple rectangular geometry. In most cases the model contains two distinct material regions, shown in Figure 1. This model undergoes a uniform compression, as shown in Figure 2, and the resulting configuration is chosen as the geometry for the descendent model, as shown in Figure 3. Models with axisymmetric elements are placed at a large radial position so that the element behavior is near to that of plane strain elements. Models with three-dimensional elements have a depth of 10 units and have meshes slightly different from those shown in the following planar mesh figures.    Mesh:Material:Material properties are selected from among the following models. In cases where two different material properties are used in adjacent regions, the parameters listed first are applied to one material region and the parameters listed second are applied to the other: Elastic (including UMAT implementation)

Elastic/plastic

Hyperelastic

Boundary conditions:The ancestor model is constrained from vertical motion on the bottom surface and from horizontal motion along the interface between the material regions. The top surface is then compressed with a uniform motion while the sides expand with a prescribed, volume preserving motion. These boundary conditions result in a deformed configuration that is independent of the material models used in the analysis. In some tests the deformed configuration shown in Figure 2 is reached at an intermediate step and increment, which enables testing of solution mapping from intermediate configurations. Ancestor models with temperature degrees of freedom have a temperature of zero prescribed on the lower boundary and a temperature of 1000 prescribed on the upper boundary, resulting in a linear variation in temperature across the height of the model. Ancestor models with pore pressure degrees of freedom have a pore pressure of zero prescribed on the lower boundary and a pore pressure of 1 prescribed on the upper boundary, resulting in a linear variation in pore pressure across the height of the model. Results and discussionThe material solution variables in each descendent model are verified to match those in the ancestor model in its deformed configuration. In cases where the models have distinct material regions, the solution variables in the descendent model are verified to be distinct with no smoothing across the material boundary. The linear distribution in temperature in models with temperature degrees of freedom and in pore pressure in models with pore pressure degrees of freedom is verified to agree between the ancestor and the descendent model. Input filesThe input file names describe the analysis procedure, element type, and material type. The input files are grouped in pairs; each pair is comprised of an ancestor model, from which the solution is transferred, and a descendent model, to which the solution is transferred. The ancestor analysis files follow the format pmap_element_material_options_a.inp; the descendent analysis files follow the format pmap_element_material_options_d.inp. element indicates the element type or types used in the analysis. material indicates the type of material in the analysis. options indicates the particular procedure or feature tested. CPE8 element tests:

| |||||||||||||||||||||