User subroutine tested in a stress/displacement analysis

Elements tested

B31

Features tested

User subroutine to define frictional behavior for contact surfaces in a stress/displacement analysis.

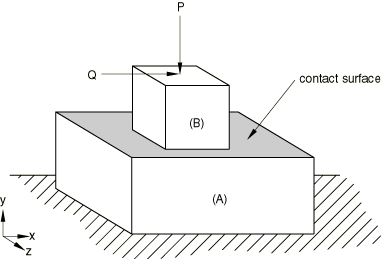

Problem description

Abaqus provides a Coulomb friction model as the default behavior for frictional interfaces. In this test an alternative constitutive model is used. Here, the interface is assumed to have a viscoplastic behavior so that the slip strain rate is proportional to the shear stress. For this particular example

where k=0.001.

A fairly stiff beam element is used to model a rod. The contact between the bottom end of the rod and a three-dimensional rigid surface is modeled by specifying a main-secondary contact pair. The bottom end of the rod constitutes the node-based secondary surface, and the rigid surface represents the main surface. The rigid surface is kept fixed in space throughout the analysis and corresponds to the x–y plane. This configuration is shown in Figure 1. The rod, which is perpendicular to the rigid surface (that is, parallel to the z-axis), is forced into contact with the rigid surface and kept in compression by applying a concentrated load in the axial direction at the top of the rod. Subsequently, the rod is forced to slide around the surface by applying a concentrated load vector of the form

to the node at the top of the beam element. All rotations are constrained on this node as well.

The first two steps of the analysis set up an equilibrium solution in which the beam element is compressed by a force of 100. The rod is then slid in three steps (Steps 3–5), and each of the steps has a total time of unity. A tangential force of norm 100 is applied instantaneously during each of these steps to keep the norm of the shear stress vector constant. During these three steps the incremental slip vector and the interfacial shear stresses are checked for consistency with the assumed constitutive law.

Reference solution

- STEP 3:

A constant tangential force =100 and =0 is applied. The total slip at the end of this step is 0.1 along the x-axis since the applied shear stress is held constant with a value of 100 along this axis.

- STEP 4:

A constant tangential force ==70.71 is applied. The total slip at the end of this step is .17071 in the x-direction and .07071 in the y-direction since the applied shear stress is held constant with a value of 70.71 in each direction.

- STEP 5:

A constant tangential force =0 and =100 is applied. The total slip at the end of this step is .17071 in each direction since the applied shear stress is held constant with a value of 100 along the y-axis.

Results and discussion

The results match the analytical solution for Steps 3, 4, and 5.

Input files

- ufricxxx.inp

-

Stress/displacement analysis.

- ufricxxx.f

-

User subroutine FRIC used in ufricxxx.inp.