Unidirectional solution transfer between Abaqus/Standard and FLUENT

Elements tested

CPS4I

Features tested

Unidirectional coupling between Abaqus/Standard and FLUENT; and

transfer of normal surface pressure and concentrated forces.

Problem description

This verification problem illustrates the co-simulation feature used to couple Abaqus/Standard with FLUENT to perform a fluid-structure interaction (FSI) simulation. The problem consists of a slender cantilever beam placed inside a channel with steady, incompressible, laminar flow. For this case a unidirectional coupling is considered in which fluid pressure along the cantilever beam is computed by FLUENT and is imported into Abaqus. The problem is simple such that comparison between the numerical and analytical results can be made.

Model:

The model consists of a slender cantilever beam inside a channel, as illustrated in Figure 1. The beam length is 1 m, and the thickness is 0.01 m. The depth is considered sufficiently large so that end effects can be neglected and the flow can be considered independent of the z position. A 0.1 m slice of the beam and channel is chosen for this model. The FLUENT model contains two fluid domains that are distinct at one end and merge at the opposite end of the beam: the top channel height is 0.02 m, and the bottom channel height is 0.04 m. The channel cross-section is uniform along the beam.

Mesh:

A two-dimensional model is used. The mesh consists of incompatible mode plane stress elements: 100 elements along the length, and 4 elements stacked in the thickness direction. No mesh parameter studies were performed on the structural mesh. The fluid-structure interface is defined through a surface definition.

The fluid mesh consists of 200 quadrilateral cells along the channel length and 8 cells and 16 cells stacked in the top and bottom channels, respectively. Quadrilateral fluid cells were used since these generally provide better pressure results than triangular fluid cells at the faces.

Material:

The structural model uses linear elastic properties with Young's modulus of 1.09 GPa and a Poisson's ratio of 0.3.

The fluid model assumes incompressible flow with a fluid density of 1000 kg/m3 and a dynamic viscosity of 0.001 kg/ms.

Boundary conditions:

The structure is fixed on the inlet end of the channel and free at the outlet end. The velocity inlet flow corresponds to a Reynolds number of 250 in the upper channel and 354 in the lower channel. A pressure outlet with a zero gauge pressure is specified at the outlet, implying that the fluid of the top and bottom channel merge and have the same pressure condition. A fully developed flow is assumed and is specified through the FLUENT user-defined function fsi_channel_2d.c for two-dimensional problems and fsi_channel_3d.c for three-dimensional problems.

Loading:

The fluid flow induces both normal pressure and viscous shear forces on the cantilever. The viscous shear forces are relatively small. The cantilever deforms due to the pressure difference in the top and bottom channels.

Analytical results

A fully developed flow is assumed through the uniform cross-section channel with an incompressible fluid. Thus, the y-velocity component () and the gradient of the x-velocity component () are zero everywhere; and the governing Navier-Stokes equation for the fluid flow is

where y represents a local coordinate system of each channel, represents the cantilever interface, and represents the channel wall. The flow at the fluid-structure interface and the channel wall are zero. Thus, at and for both the top and bottom channels.

Substituting the boundary condition and integrating the Navier-Stokes equation leads to the flow solution for each channel:

The mean velocity, , is defined as the integral of the flow solution over the channel cross-sectional area divided by the cross-sectional area. Assuming a unit depth,

Solving for the pressure gradient, you obtain a linear pressure distribution in each channel,

where is the gauge pressure at the outlet.

The deformation of a cantilever beam subjected to a triangular distributed pressure is given by

where is the pressure at the inlet end.

The tip deflection due to the flow in each channel is

Since the flow fields merge and the structure is linear, you can superimpose the results for both channels.

Units

The SI unit system is used. Abaqus does not require that the analysis be run with a particular unit system as long as all properties are specified in a consistent manner. However, the unit system used by Abaqus must coincide with those used by the third-party analysis code.

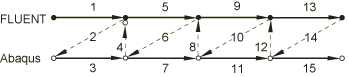

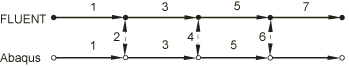

Coupling scheme

A unidirectional coupling scheme, illustrated in Figure 2, is employed with FLUENT designated to begin the exchange process by sending its exchange information first. FLUENT computes the flow field around the undeformed cantilever (arrow 1) and sends the pressure distribution to Abaqus (arrow 2). Abaqus then computes the deformation corresponding to the pressure field during the first increment (arrow 3).

Running the co-simulation

The following procedure illustrates how to run the co-simulation using the MpCCI project file:

The Abaqus and FLUENT problem files should be copied to the appropriate product directories: problemDir/ABAQUS and problemDir/FLUENT, and the MpCCI project file should be copied into the problemDir directory.

From the problemDir directory, submit the MpCCI project file to MpCCI GUI in batch mode:

mpcci -batch example.csp

Results and discussion

Based on the analytical derivation for normal pressure distribution, the expected tip deflection is –1.235 × 10−4 m. The simulation results are shown in Table 1 for a case in which normal pressure (PRESS) is imported into Abaqus and a case in which concentrated forces (CF) are imported into Abaqus.

| Element | Tip Deflection (m) (PRESS) | Tip Deflection (m) (CF) |

|---|---|---|

| CPS4I | –1.202 × 10−4 (–2.7%) | –1.202 × 10−4 (−2.7%) |

The pressure difference between the top and bottom channels reported by FLUENT shows a –2.7% difference compared with the analytically predicted pressure difference. This discrepancy is consistent with the differences observed in the tip deflections. Viscous shear forces, which are not consistent with the analytical derivation, are transferred in addition to the normal pressure forces for cases in which concentrated forces are exchanged. These viscous shear forces are relatively small.

Input files

Unidirectional transfer

- fsi_channel_cps4i_pr_1-way.inp

Abaqus input file for unidirectional transfer with pressure loads imported.

- fsi_channel_cps4i_cf_1-way.inp

Abaqus input file for unidirectional transfer with concentrated forces imported.

- fsi_channel_cps4i_pr_1-way.csp

MpCCI GUI project file for fsi_channel_cps4i_pr_1-way.inp.

- fsi_channel_cps4i_cf_1-way.csp

MpCCI GUI project file for fsi_channel_cps4i_cf_1-way.inp.

- fsi_channel_2d.cas

FLUENT case file for all two-dimensional models.

- fsi_channel_2d_1-way.jou

FLUENT journal file for all unidirectional transfers.

- fsi_channel_2d.c

FLUENT user-defined function for two-dimensional laminar flow.