Creating a Fillet Weld | ||

| ||

-

From the Weld section of the action bar, click Fillet Weld

.

.

- Select a weld body in the tree.

-

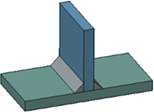

Select both of the faces to join.

Tips: - To add or remove faces defining the supports (as displayed in the Supports list), press Ctrl + Click.

- You can add to or remove faces from a support using

the

Edit selection

context menu

from the

Supports list.

- Clicking a face in the work area adds it to the list.

- To remove a face from the list, use Remove selection.

- Optional: If the parts are not perfectly in contact with each other, you can weld them together using the With Gap option.

-

Optional: Click

Preview.

The fillet weld section appears and the edge where it will be propagated is highlighted.

-

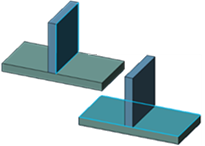

To create another weld, select the following face as support.

-

Click

Preview.

The fillet weld sections appear. The edges where they will be propagated are highlighted.

-

To specify the weld size, select an option:

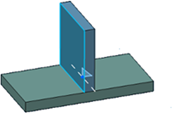

- Throat: Defines the throat length. The a

symbol represents the throat.

- Leg Length: Defines both leg lengths.

The z symbols represent the legs.

To assign a distinct value to Leg 2, first select Leg Length 2.

- Throat: Defines the throat length. The a

symbol represents the throat.

-

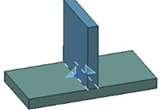

Optional: To define the shape of the weld, click the

Manufacturing tab and select an option. The shape

defines the weld seam shape representation in drafting context. If you select

Convex

or

Concave

or

Concave

, specify a curvature value in

Offset.

The offset is the maximum distance between the weld

face and arc.

, specify a curvature value in

Offset.

The offset is the maximum distance between the weld

face and arc.

For more information about manufacturing options, see Manufacturing.

Note: Shapes are extracted on drawings. - Optional: To specify a dashed weld, click the Type tab and select a creation mode. For more information, see Creating a Dashed Weld.

-

Click

OK.

The fillet weld is created. It appears with aggregated supports and external references in the tree.