-

From the Weld section of the action bar, click V-Butt Weld

. .

-

Select a weld body in the

tree.

-

Select the following faces as supports.

- Optional: To trim the weld to a surface or another weld, select the limits.

- Optional: Change the angle value for the weld.

- Optional:

Increase the thickness.

- Optional: To extend the weld, enter a value in Extrapol Length.

- Optional:

Click

Preview.

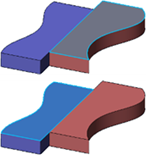

The V-Butt weld section appears. The edge along which it will

be propagated is highlighted.

-

Optional: To define the shape of the weld, click the

Manufacturing tab and select an option. The shape

defines the weld seam shape representation in drafting context. If you select

Convex

or

Concave or

Concave

, specify a curvature value in

Offset.

The offset is the maximum distance between the weld

face and arc. , specify a curvature value in

Offset.

The offset is the maximum distance between the weld

face and arc.

For more information about manufacturing options,

see

Manufacturing.

Note:

Shapes are extracted on drawings.

-

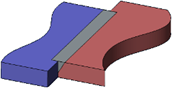

Optional: Select

Generate Weld Impacts.

The app performs a Boolean subtract of the weld shape from the

plates being welded.

-

Click

OK.

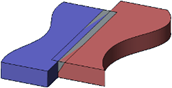

The V-butt weld is created but the affected representations are not yet prepared for

the welding.

-

Click

Update

. .

The affected representations are prepared for the welding.

- The v-butt weld appears in the tree.

- Its supports and their external references appear under the

V-butt weld.

- External references appear under the

External References node too.

- An assembly protected weld preparation is created and appears under the

Assembly features

node. node.

- The welded 3D shapes are prepared.

|

.

.

or

Concave

or

Concave

, specify a curvature value in

Offset.

The offset is the maximum distance between the weld

face and arc.

, specify a curvature value in

Offset.

The offset is the maximum distance between the weld

face and arc.

.

The affected representations are prepared for the welding.

.

The affected representations are prepared for the welding.

node.

node.

appears as a feature in the PartBody including

impacted 3D shapes. A rep impact

appears as a feature in the PartBody including

impacted 3D shapes. A rep impact  is created, maintaining a link between the root

product under which the bundle of weld, weld body, and welds are created.

Rep impact appears under Impacts manager

is created, maintaining a link between the root

product under which the bundle of weld, weld body, and welds are created.

Rep impact appears under Impacts manager

.

.