Introductory Concepts | ||

| ||

About Import/Export of External Data

For more information, see About the Import/Export of External Data in Composites Design User's Guide.

Laser Projection Export and Laser Projection File Reader support .ply, .cal, .xml, .lg, .lpd file formats.

You can open or save external data as reference objects in a PLM database. External references are VPM Documents used to store files.

At export, the 3D Shape is attached to the created or existing PLM external data reference. This enables you to find feature changes since last export. This also provides reusability of the PLM references for export purpose.

- The root reference is a 3D physical product structure.

- The VPM Document is attached to the root reference.

- You have to manage the maturity of the 3D Shape and associated VPM Document.

- You can create several documents with the same name, but their Product Lifecycle Management Identifier (PLMId) must be unique.

The commands listed below support import or export, both in a file-based system and a database. The last column lists features used for traceability when importing/exporting to a database.

| Command | Action | Feature Used for Traceability | Created Specific Values |

|---|---|---|---|

| Laser Projection Export | Export | Stacking | Composites Laser Data |

| Laser Projection File Reader | Import File | - | - |

Laser Projection Export

When generating laser projection information, you can complete plies and points information with:

- Additional Geometries, taken into account provided

Laser Projection Export has been selected at their

creation.Note: If Core Sample Scope is Stacking or Plies Group, only the plies under the core (if any),not the core itself, are taken into account. Added geometry found inside the core footprint is not elevated.

- Stacking Texts defined in Composites Design or Composites Manufacturing Preparation.

- Projected Texts if the option is selected in Laser Projection Preferences.

Laser Projection Export is done in two main steps: Discretization, then elevation.

- As soon as entities are selected, all the curve-type geometries for each ply/cut-piece

are discretized. They can be

- Inner and outer ply contours

- Additional curve-type geometries

- Guide curves

- Orders of drape.

- Discretization points are elevated from the reference surface taking the cured or uncured thickness into account. The thickness is given by a core sample.

- Sag, Step, and

Angle can be customized as follows.

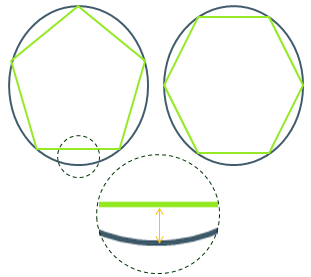

- Sag (Shown by the double-headed arrow) is the maximum

distance or deviation between the geometry (shown in blue) and the trajectory

between the points (shown in green). The effect of a larger value is shown on the

left, of a smaller value on the right.

A larger sag value reduces the number of points to the extent where the step value is reached. A smaller sag value increases the amount of points to meet the sag value. As the number of points grows, so does the size of the output file. - Step (shown by the double-headed arrow) is the minimum

linear distance between any 2 given points. The effect of a larger value is shown on

the left, of a smaller value on the right.

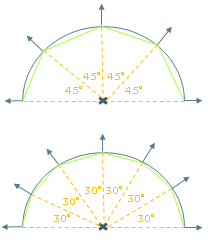

A smaller step value adds more points to ensure that all steps meet the defined minimum distance. Smaller step distances can improve the accuracy of plies in areas where plies are consecutively dropping off (transition zones). The default value is high enough to avoid adding unnecessary points.Recommendation: Adjust the value as required. - Angle is the maximum angle approximation between adjacent

trajectories. Allowed values are between 12 and 45 degrees. Points are added or

removed based on the angle value where sag and step values are too large for high

curvature geometry and do not provide the proper resolution. Decreasing the sag and

step values adds significantly more points uniformly to all geometries concerned and

is not dealt with in most cases. In the example below, when the angle value is 45

degrees (default value), the trajectory is not optimally smooth (shown in green).

When the angle value is decreased to 30 degrees, points are added and the trajectory

is smoother (shown in green).

- Sag (Shown by the double-headed arrow) is the maximum

distance or deviation between the geometry (shown in blue) and the trajectory

between the points (shown in green). The effect of a larger value is shown on the

left, of a smaller value on the right.

- The rosette is transferred at the seed point, if any, at the computed central point otherwise.

As soon as a discretization is done, a preview tree displays the elements to export and the projectors, enabling you to verify the elements.

Laser Projection File Reader

As in export, a preview tree displays the read elements.

Preview Tree

The preview tree displays the elements to export or to read in nodes, according to the options selected in Laser Projection Preferences.

- The information in the preview tree is very similar in Laser Projection Export and Laser Projection File Reader. However, less information is provided at reading (contour information or projector information, for example).

- Select a node in the preview tree to verify the elements in the node. This does not select the elements for export.

Each element node corresponds to:

- A LAYER level in VIRTEK format.

- An xml node level in LPT format.

- A PLY command in LASERGUIDE format.

- A DRAWING/LAYER/GROUP in LAP format.

Ply and cut-piece nodes contain detail nodes for each element:

- Rosette

- Contours

- Guide curve

- Order of drape contours

- Additional geometries:

- Like ply geometries, all visible curve-type geometries found in Additional Geometries Sets are discretized and exported.

- Closed curves are marked as Additional contours in the corresponding node.

- Open curves are marked as Additional curves.

- In all formats, the curves and contours are exported as the other ply geometries (contours, seed curves, ...).

- Stacking Texts are inserted in the preview tree, and exported in the file, at the same position they

have in the 3D area

tree. The type of the text is given between brackets.

- Text (projected) if the text is with 3D representation and

if 3D option is chosen as its laser projection type. It is

projected on the mold alongside the other geometries.

- For VIRTEK format:

- Text (information) if Information option is chosen as its laser projection type. It is displayed on the console.

- Text (query) if Query option is chosen as its laser projection type. It is displayed on the console and validation is requested.

- Text (LED) if LED option is chosen as its laser projection type. It is displayed on the LED display.

- For LPT format:

- Text (information) if Information, Query, or LED option is chosen as its laser projection type. It is displayed on the console.

- Ignored (no node) if 3D Stacking Text is outside plies or cut-pieces.

- For LASERGUIDE format:

- Comment if Information, Query, or LED option is chosen as its laser projection type.

- Ignored (no node) if 3D Stacking Text is outside plies or cut-pieces.

- For LAP format: Ignored (no node) if Information, Query, or LED option is chosen as its laser projection type or if Stacking Text is outside plies or cut-pieces.

- For VIRTEK format:

- Automatic text when Projected Text is

selected.

The text is added under each ply or cut-piece node in the preview tree and therefore in the corresponding LAYER (VIRTEK format), xml node (LPT format), PLY block (LASERGUIDE format) or GROUP (LAP format).

The text is displayed in the preview tree as Automatic Text (projected).

It is visible in the 3D area when the node is selected (or its parent ply node).

3D representation is the same as a Stacking Text with 3D representation and placed below the transferred rosette, in the same plane as the rosette and along the x direction of the rosette.

- Text (projected) if the text is with 3D representation and

if 3D option is chosen as its laser projection type. It is

projected on the mold alongside the other geometries.

Display Options

Display options are proposed in Laser Projector, Laser Projection Export and Laser Projection File Reader. Although similar, they vary from one command to the other.

- Normal Vectors

.

They are colored green, yellow, or red depending on the angle they form with the ray

line from the projector to the discretization point. When no projector is available, the

vectors are colored green. When several projectors are available, the color of the

normal vector is that of the shortest ray with an angle below the warning angle. The aim

is to verify that the plies and cut-pieces can be projected, not to show all

solutions.

.

They are colored green, yellow, or red depending on the angle they form with the ray

line from the projector to the discretization point. When no projector is available, the

vectors are colored green. When several projectors are available, the color of the

normal vector is that of the shortest ray with an angle below the warning angle. The aim

is to verify that the plies and cut-pieces can be projected, not to show all

solutions. - Original Contours

of the ply

or cut-piece on the reference surface to be compared with the discretized ones.

of the ply

or cut-piece on the reference surface to be compared with the discretized ones. - Laser Projection Rays

that

are the lines from the projector to the discretization points. When several projectors

are available, for each discretization point, the projector considered is the closest

projector with a ray-normal angle smaller than the warning angle.

that

are the lines from the projector to the discretization points. When several projectors

are available, for each discretization point, the projector considered is the closest

projector with a ray-normal angle smaller than the warning angle. - Vertical Limit Planes

with respect to the maximum vertical angle of the projector.

with respect to the maximum vertical angle of the projector. - Horizontal Limit Planes

with respect to the maximum horizontal angle of the projector.

with respect to the maximum horizontal angle of the projector. - Size of Normal Vectors

- Color of the Projector Rays and of the Projected Elements

Examples of Files

Extract of a .ply file

LAYER START Plies Group.1 LAYER START Sequence.1 LAYER START Ply.1 START Ply.1 P 3 242.604 62.809 -72.223 0 0.652 0.758 222.679 48.544 -58.311 0 0.698 0.716 212.716 55.676 -65.267 0 0.676 0.737 P 31 212.5 112.41 -105.855 0 0.474 0.88 150 112.41 -105.855 0 0.474 0.88 87.5 112.41 -105.855 0 0.474 0.88 25 112.41 -105.855 0 0.474 0.88 25 102.132 -100.009 0 0.514 0.858 25 92.194 -93.747 0 0.552 0.834 25 82.596 -87.102 0 0.586 0.81 25 73.331 -80.102 0 0.619 0.786 25 67.332 -75.249 0 0.639 0.769 25 61.471 -70.254 0 0.658 0.753 25 50.139 -59.856 0 0.693 0.721 25 40.781 -50.488 0 0.721 0.693 25 31.77 -40.748 0 0.747 0.665 25 23.095 -30.643 0 0.77 0.638 25 14.748 -20.18 0 0.793 0.61 87.5 14.748 -20.18 0 0.793 0.61 150 14.748 -20.18 0 0.793 0.61 212.5 14.748 -20.18 0 0.793 0.61 275 14.748 -20.18 0 0.793 0.61 275 23.095 -30.643 0 0.77 0.638 275 31.77 -40.748 0 0.747 0.665 275 40.781 -50.488 0 0.721 0.693 275 50.139 -59.856 0 0.693 0.721 275 61.471 -70.254 0 0.658 0.753 275 67.332 -75.249 0 0.639 0.769 275 73.331 -80.102 0 0.619 0.786 275 82.596 -87.102 0 0.586 0.81 275 92.194 -93.747 0 0.552 0.834 275 102.132 -100.009 0 0.514 0.858 275 112.41 -105.855 0 0.474 0.88 212.5 112.41 -105.855 0 0.474 0.88 END Ply.1 LAYER END Ply.1 LAYER END Sequence.1

Extract of .cal file

4 T 1 D 25 162.459 -126.061 T 2 D 275 162.459 -126.061 T 3 D 160.121 71.803 -104.222 T 4 D 222.679 48.404 -58.454

Extract of .xml file (plies information)

<?xml version="1.0"?> -<XML> -<PART TopLayers="3" HIGHESTPLY="135" USEASSIGNEDLASERS="" DEFAULTLASER="0" MODIFIED="2016-03-03-11.28.13" INVERTNORMALS="" DBVERSION="" STATUS="" NAME="vmua"> -<PLY NAME="L1-Ply.40"> -<PLY NAME="L2-Ply.40:0" LASERNUMBER="1"> <POINT NAME="" KVAL="-0.727" JVAL="-0.687" IVAL="0" ZVAL="-95.185" YVAL="69.445" XVAL="183.016" NUMBER="1"/> <POINT NAME="" KVAL="-0.727" JVAL="-0.687" IVAL="0" ZVAL="-70.899" YVAL="43.751" XVAL="147.661" NUMBER="2"/> <POINT NAME="" KVAL="-0.727" JVAL="-0.687" IVAL="0" ZVAL="-22.326" YVAL="-7.637" XVAL="218.372" NUMBER="3"/> </PLY> -<PLY NAME="L3-Ply.40:1" LASERNUMBER="1"> <POINT NAME="" KVAL="-0.567" JVAL="-0.824" IVAL="0" ZVAL="-10.856" YVAL="-7.371" XVAL="295" NUMBER="1"/> <POINT NAME="" KVAL="-0.644" JVAL="-0.765" IVAL="0" ZVAL="-41.197" YVAL="15.753" XVAL="295" NUMBER="2"/> <POINT NAME="" KVAL="-0.721" JVAL="-0.693" IVAL="0" ZVAL="-68.791" YVAL="41.541" XVAL="295" NUMBER="3"/> <POINT NAME="" KVAL="-0.811" JVAL="-0.585" IVAL="0" ZVAL="-97.36" YVAL="75.621" XVAL="295" NUMBER="4"/> <POINT NAME="" KVAL="-0.855" JVAL="-0.519" IVAL="0" ZVAL="-109.87" YVAL="94.472" XVAL="295" NUMBER="5"/> <POINT NAME="" KVAL="-0.896" JVAL="-0.443" IVAL="0" ZVAL="-121.294" YVAL="114.414" XVAL="295" NUMBER="6"/> <POINT NAME="" KVAL="-0.958" JVAL="-0.287" IVAL="0" ZVAL="-137.171" YVAL="151.744" XVAL="295" NUMBER="7"/> <POINT NAME="" KVAL="-0.981" JVAL="-0.192" IVAL="0" ZVAL="-143.754" YVAL="171.65" XVAL="295" NUMBER="8"/> <POINT NAME="" KVAL="-0.997" JVAL="-0.081" IVAL="0" ZVAL="-147.64" YVAL="192.329" XVAL="295" NUMBER="9"/> <POINT NAME="" KVAL="-0.999" JVAL="0.039" IVAL="0" ZVAL="-148.088" YVAL="212.618" XVAL="295" NUMBER="10"/> <POINT NAME="" KVAL="-0.985" JVAL="0.172" IVAL="0" ZVAL="-145.959" YVAL="232.783" XVAL="295" NUMBER="11"/> <POINT NAME="" KVAL="-0.935" JVAL="0.356" IVAL="0" ZVAL="-138.644" YVAL="259.427" XVAL="295" NUMBER="12"/> <POINT NAME="" KVAL="-0.853" JVAL="0.522" IVAL="0" ZVAL="-126.175" YVAL="284.729" XVAL="295" NUMBER="13"/> <POINT NAME="" KVAL="-0.853" JVAL="0.522" IVAL="0" ZVAL="-126.175" YVAL="284.729" XVAL="5" NUMBER="14"/> <POINT NAME="" KVAL="-0.935" JVAL="0.356" IVAL="0" ZVAL="-138.644" YVAL="259.427" XVAL="5" NUMBER="15"/> ...</PLY> <TEXT NAME="1" PT3ZVAL="26.246" PT3YVAL="-59.025" PT3XVAL="147.661" PT2ZVAL="-22.326" PT2YVAL="-7.637" PT2XVAL="218.372" PT1ZVAL="-70.899" PT1YVAL="43.751" PT1XVAL="147.661" VALUE="Ply.40"/> </PLY> </PART> </XML>

Extract of .xml file (target points information)

<?xml version="1.0"?> -<XML> -<TOOL TOOLCODE="" STATUS="" COORDSYSTEM="RIGHT" MODIFIED="2016-03-03-11.28.14" NAME="vmub" DBVERSION=""> <TARGET NAME="Point.1" SEARCHRATIO="1.0" ZVAL="-126.061" YVAL="162.459" XVAL="275" DVAL="Y" LASERNUMBER="1" NUMBER="1"/> <TARGET NAME="Point.19" SEARCHRATIO="1.0" ZVAL="-101.832" YVAL="68.518" XVAL="195.779" DVAL="Y" LASERNUMBER="1" NUMBER="2"/> <TARGET NAME="Point.20" SEARCHRATIO="1.0" ZVAL="-80.933" YVAL="43.099" XVAL="79.575" DVAL="Y" LASERNUMBER="1" NUMBER="3"/> <TARGET NAME="Point.21" SEARCHRATIO="1.0" ZVAL="-151.805" YVAL="197.793" XVAL="73.237" DVAL="Y" LASERNUMBER="1" NUMBER="4"/> <TARGET NAME="Point.22" SEARCHRATIO="1.0" ZVAL="-151.629" YVAL="194.743" XVAL="182.877" DVAL="Y" LASERNUMBER="1" NUMBER="5"/> <TARGET NAME="Point.8" SEARCHRATIO="1.0" ZVAL="-76.567" YVAL="38.393" XVAL="147.661" DVAL="Y" LASERNUMBER="1" NUMBER="6"/> </TOOL> </XML