Assignment Assistant Overview

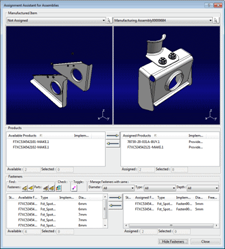

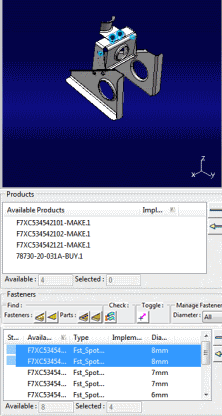

The Assembly Assignment Assistant can be used to assign

products and fasteners to items.

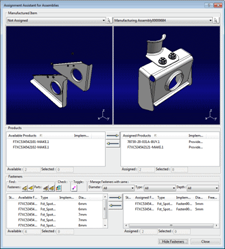

The assignment assistant dialog box appears when you select Assembly

Assignment Assistant

. .

Click the image to enlarge it:

The assistant comprises the following main parts: Items, Products, Fasteners, and 3D viewer.

Selection and Display

When you select an item in the right-hand and left-hand item lists, all products

implemented by this item are displayed in the corresponding 3D viewer. These products

are also listed in the Available Products and Assigned

Products lists under the 3D viewer.

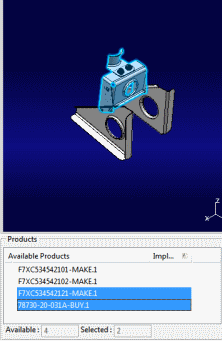

Selecting Not Assigned in the left-hand item list displays the

products that are available for assignment. Note:

If the product is not declared as

Manufacturable/Procurable, it does not appear in the

Available Products list and the 3D viewer.

When you select an item in the right-hand item list, the list of unassigned products

is updated.

A product that is assigned to a predecessor is identified as Output of:

<predecessor> in the Products list and is

displayed in the 3D viewer. However, it is not available for assignment. Selecting

the Output of: line in the list highlights the resulting

product in the viewer. Similarly, selecting the product in the viewer highlights the

Output of: line in the list.

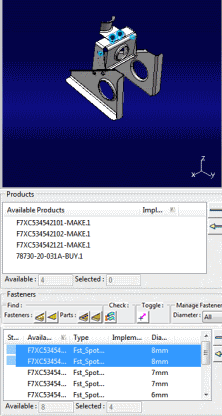

When you click the Show Fasteners command, a

Fasteners frame appears under the

Products frame, allowing you to manage the consumption of

fasteners. The behavior is the same as for products. For more information, see Fastener Assignments and Additional Options. However, fasteners assigned on predecessors are not available in the Fasteners

list and are not displayed in the 3D viewer.

The 3D viewer offers Zoom, Pan, and Trap Selection capabilities, as well as a menu.

Cross highlighting is available between the 3D viewer and the lists in the assistant.

Note:

In this document, objects in left-hand lists are known as source objects and

objects in right-hand lists are known as destination objects.

Center Tree and Reframe on Selection for Products

Product Assignments

The assignment assistant allows you to assign, unassign, or reassign a

product, or a list of products between two items.

This is done using the assignment arrows  and and  as

follows: as

follows:

- Assigning a product from Not Assigned to a

destination item creates a Provided Part under the destination

item.

- Assigning a product from a Manufacturing Assembly to Not

Assigned unassigns this product from the Manufacturing Assembly and deletes the corresponding Provided Part.

- Assigning a product from a source Manufacturing Assembly and a destination Manufacturing Assembly unassigns it from the source and assigns it to the destination.

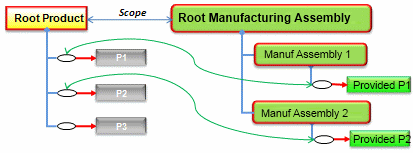

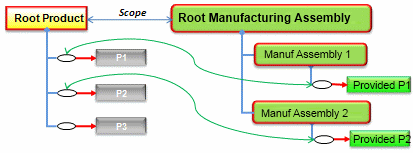

In the following example, Products P1, P2, and

P3 are instantiated under a Root Product:

- Product P1 is implemented by Provided Part

P1; Provided Part

P1 is instantiated under Manufacturing Assembly

1

- Product P2 is implemented by Provided Part

P2; Provided Part

P2 is instantiated under Manufacturing Assembly

2

- Product P3 is available for assignment on Manufacturing Assembly

1 or Manufacturing Assembly

2.

- Assigning Product P3 to Manufacturing Assembly

1 creates a Provided Part

P3 that is instantiated under Manufacturing Assembly

1.

- Unassigning Product P1 from Manufacturing Assembly

1 deletes Provided Part

1.

- Reassigning Product P1 from Manufacturing Assembly

1 to Manufacturing Assembly

2 deletes Provided Part

P1 under Manufacturing Assembly

1 and creates another Provided Part

P1 instantiated under Manufacturing Assembly

2.

Note:

The assignment arrows in the assistant are disabled if:

- the source and destination products reference the same Manufacturing Assembly.

- no products are available for assignment in source and destination.

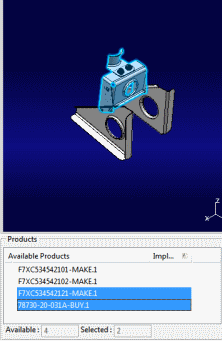

Under the source products list and the destination products list, there are two

fields:

- Available or Assigned:

displays the number of available or assigned products under the selected

item.

- Selected: displays the number of selected products.

Fastener Assignments and Additional Options

When you click Fasteners in the assignment assistant, a

number of additional options become available for managing product and fastener

assignments, including automatic assignment and validity checks.

When the Fasteners frame appears under the

Products frame in the assignment assistant, you can

manage the consumption of the fasteners.

The behavior is the same as for products: fasteners can be assigned, unassigned, and

reassigned, although, instead of a Provided Part, a Fasten step is created for each fastener and instantiated under the item on which the

fastener is assigned.

Find Fasteners Options

A number of options are available to find fasteners.

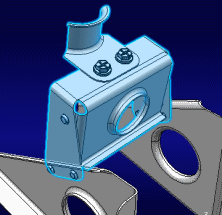

Find Fasteners Joining Selected Parts

The

Find Fasteners Joining Selected Parts

option allows you to identify the fasteners that

join selected parts. It highlights these fasteners in the lists and 3D

viewers. option allows you to identify the fasteners that

join selected parts. It highlights these fasteners in the lists and 3D

viewers.

|

Selected parts:

|

Joining fasteners:

|

Find Fasteners Linked to Selected Parts

The

Find Fasteners Linked to Selected Parts

option allows you to identify the fasteners that

are directly linked to selected parts. It highlights these fasteners in the

lists and 3D viewers. option allows you to identify the fasteners that

are directly linked to selected parts. It highlights these fasteners in the

lists and 3D viewers.

Find Parts Options

A number of options are available to find parts.

Find Parts Joined by

Selected Fasteners The Find Parts Joined by Selected

Fasteners

option selects and highlights the parts that are

joined by one or more selected fasteners. option selects and highlights the parts that are

joined by one or more selected fasteners.

Find Parts Linked to Selected

Parts The Find Parts Linked to Selected

Parts

option selects and highlights parts that are linked

to the selected parts by at least one fastener. option selects and highlights parts that are linked

to the selected parts by at least one fastener. Check the Status of Assigned Fasteners

The Check the Status of Assigned Fasteners option

verifies the validity of the assigned fasteners.

It verifies if the fasteners assigned to a destination assembly join all

products assigned to the same assembly (or item):

- If a fastener is valid, a green check mark

is

displayed next to the fastener name in the fasteners list. is

displayed next to the fastener name in the fasteners list.

- If a fastener is not valid, a red cross mark

is

displayed next to the fastener name in the fasteners list. is

displayed next to the fastener name in the fasteners list.

The last two fasteners join the assigned products: they are valid. All products

joined by the first two fasteners are not assigned: these fasteners are not

valid. Note:

The fasteners list can be sorted by status.

In addition to the fastener names and status, the following information is given

in the corresponding lists:

- the implementing Fasten step

- the fastener type, which is user-defined

- the diameter of the fastener.

Toggle Fastener Axis Representation

The Toggle command lets you display or hide the

fastener axes in the 3D viewers.

The arrow on the axis representation shows the orientation of the fastener.

Manage Fasteners with Same Diameter and Type

You can filter the fasteners displayed in the fasteners lists by

diameter, by type, or both.

The fastener lists display the available diameters and types of fasteners

according to the selected Diameter and

Type filter criteria.

Assignable Parts/Fasteners in Context

The Assignable Parts/Fasteners in Context option

allows you to list the fasteners linked to or joining a group of parts, or to

list parts joined by a group of fasteners.

The fasteners or parts

are listed within the scope of a selected item.

If Assignable Parts/Fasteners in Context is selected in

the left-hand item selection list, then the parts and fasteners lists are

updated according to the item selection in the right-hand side.

The right-hand viewer displays the parts and fasteners directly assigned to the

item selected in the right-hand list, as well as the input assemblies (listed as

Output of: in the parts list).

On the left-hand side, all the available parts and fasteners (assigned and not

yet assigned) in the scope and lower scopes of the right-hand item are

displayed.

Only the left-hand parts and fasteners lists remain active so you can select

parts/fasteners. Right-hand lists are disabled.

This allows you to better understand your assembly because you have access to all

parts and fasteners inside a given scope.

Freeze Status of Fasten Steps

A Freeze Status column is available in the

fasteners list.

The orange pin  icon in the column shows the Freeze status of the Fasten step implementing the corresponding fastener: icon in the column shows the Freeze status of the Fasten step implementing the corresponding fastener:

- If the implementing Fasten step is frozen, the orange pin

icon appears in the column. icon appears in the column.

- If the Fasten step is not frozen (so Released, the default status), no icon is

shown.

- If you select Not Assigned, the Freeze

Status column is not visible, as no implementing Fasten step is available for freeze/release.

To change the Freeze status on a Fasten step implementing the selected fasteners, two commands are available in the

context menu of the fasteners list:

- Freeze Selected

Fasten(s): Freezes all the Fasten steps implementing the selected fasteners and updates the

Freeze Status column.

- Release Selected

Fasten(s): Releases all the Fasten steps implementing

selected fasteners and updates the Freeze Status

column.

Note:

If no fasteners are selected or if Not

Assigned is selected, these two commands are not

available.

For more information, see Freezing or Releasing Fasten Steps Position.

Center Tree and Reframe on Selection for Fasteners

A menu is available for the left and right fasteners lists. The menu consists

of two menu items Center Tree and Reframe On

Selection.

Clicking Reframe On Selection reframes the selected product in

the 3D viewer of the appropriate list.

Center Tree contains the following submenu items:

- Clicking On Selected Fastener centers the selected

fastener in the tree.

- Clicking On Selected Fasten Step centers the selected

Fasten in the tree.

Automatic Fastener Assignment from Options

The assistant can automatically assign fasteners to items where their joined

parts are assembled, not only to the destination item.

To do so, select the Automatically

Assign and Re-assign Fasteners option in

.

Defining that option allows you to automatically assign fasteners that join movable

parts. When you select parts to assign, unassign, or reassign, all fasteners joining

these parts together are assigned on the first parent Manufacturing Assembly where the parts are assembled.

Similarly, fasteners joining these parts with already-assigned parts are assigned on

the first parent Manufacturing Assembly where the parts are assembled.

Create New or Use Existing Fasten Reference from Options

You can use the same Fasten step reference for identical fasteners.

To do so, select the Use same Fasten

step reference to implement fasteners option in

.

Identical fasteners can have the same diameter, the same type, and the same group of

joined parts.

- When the option is cleared, a new Fasten step reference is created to implement each assigned fastener in the

assistant.

- When the option is selected, the system searches for an identical fastener

according to the selected criteria (same diameter, same type, and same group

of joined parts). If a reference exists, it is used. If no reference exists,

a new reference is created.

- When none of the criteria is selected, a new reference is created.

Bead Fasteners

A bead fastener is a specific type of fastener that connects two or more

parts and whose location is defined by a 3D curve. Bead fasteners are widely used in

the automotive industry.

A bead fastener comprises the following entities:

- Fastener reference and instance

- 3D part, which defines the location of a 3D curve

The 3D parts linked to a bead fastener are not supported in the assignment assistant.

These parts are not listed in the product lists. However, their 3D representation is

used to represent the bead fastener.

When a bead fastener exists, to visualize it in the assignment assistant viewer, the

representation of the 3D part linked to it is shown in the viewer:

- Selecting the bead fastener in the fasteners list highlights the visible

representation of its 3D part in the viewer.

- Selecting the 3D part representation in the viewer highlights the bead

fastener linked to it in the fasteners list.

Bead fasteners are managed in the assignment assistant as follows:

- A Fasten step is created to implement a bead fastener.

- Unassigning a bead fastener removes the implementing Fasten step.

- Moving a bead fastener between two systems creates a new operation.

- Moving a bead fastener between two items reroutes the implementing Fasten steps.

For more information, see Product to Item Assignments.

|

![]() .

.

and

and  as

follows:

as

follows:

option allows you to identify the fasteners that

join selected parts. It highlights these fasteners in the lists and 3D

viewers.

option allows you to identify the fasteners that

join selected parts. It highlights these fasteners in the lists and 3D

viewers.

option allows you to identify the fasteners that

are directly linked to selected parts. It highlights these fasteners in the

lists and 3D viewers.

option allows you to identify the fasteners that

are directly linked to selected parts. It highlights these fasteners in the

lists and 3D viewers.  option selects and highlights the parts that are

joined by one or more selected fasteners.

option selects and highlights the parts that are

joined by one or more selected fasteners.

option selects and highlights parts that are linked

to the selected parts by at least one fastener.

option selects and highlights parts that are linked

to the selected parts by at least one fastener.